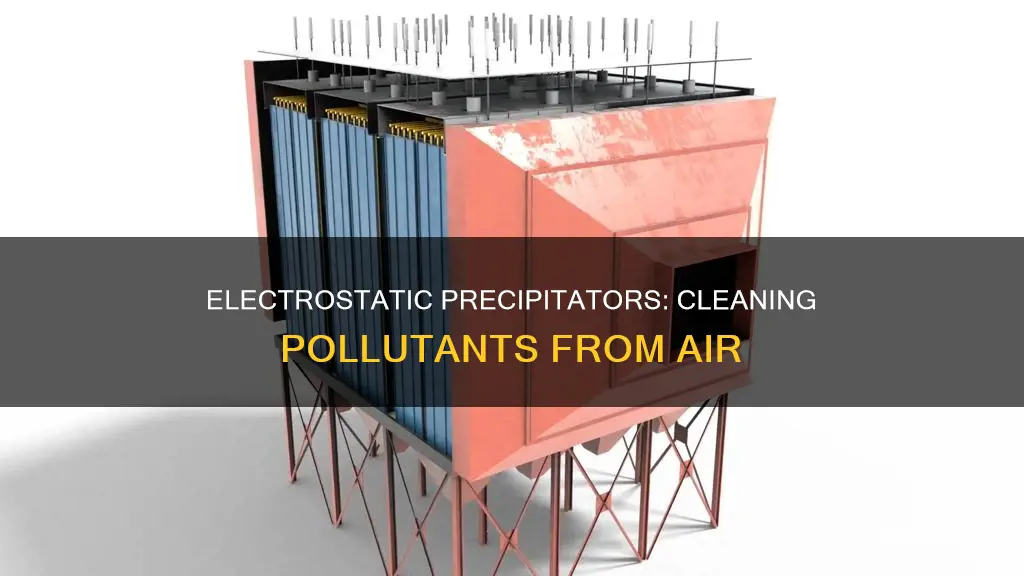

Electrostatic precipitators are devices that use electrostatic force to remove impurities from the air. They are commonly used to purify air emitted from industrial chimneys and capture particulate matter from flue gases. The basic principle behind electrostatic precipitators involves charging particles in the air stream and then collecting them using electrostatic attraction. This technology is highly effective for industrial use but has also been explored for residential settings.

What You'll Learn

- Electrostatic precipitators use static electricity to remove impurities from the air

- They are used to clean gases emitting from the metallurgical industry, coal and power plants

- They are not suitable for residential use due to the risk of ozone exposure

- They are highly effective at removing particulate matter, including fine particles

- Electrostatic precipitators were first invented in the early 20th century by Dr. Frederick Cottrell

Electrostatic precipitators use static electricity to remove impurities from the air

Electrostatic precipitators are highly effective tools for removing impurities from the air. They are commonly used in industrial settings, such as power plants and factories, to control air pollution and ensure the safety of workers. The basic principle behind electrostatic precipitators is the use of static electricity to grab and hold dust and other particles, purifying the air.

These devices consist primarily of wires and collection plates, with a high voltage applied between the wires and the collecting plates. This creates an electrostatic field that charges the air electrically and ionizes it. When airborne particles, such as dust, pollen, or smoke, flow between the collecting plates, they become charged and are attracted to the plates with the opposite charge, causing them to stick to them. The clean air then flows through, leaving the impurities behind.

The particles collected on the plates can be removed in different ways, depending on the type of electrostatic precipitator. In dry electrostatic precipitators, the particles are shaken loose, scraped off, or removed with special soak-off cleaners, while in wet electrostatic precipitators, water sprays are used to wash the particles away. The collected impurities are then safely disposed of in an environmentally friendly manner.

Electrostatic precipitators are particularly effective at capturing fine particles, even those smaller than 1 micron in diameter, which can be extremely harmful if released into the atmosphere. They can also handle large volumes of gas at various temperatures and flow rates, making them versatile and efficient. However, one of the main concerns with electrostatic precipitators is the production of ozone and nitrogen oxides, which can be harmful to human health.

Overall, electrostatic precipitators play a crucial role in air pollution control, especially in industrial settings, by using static electricity to remove impurities from the air and help protect the environment and human health.

Air Quality Forecast: What to Expect Tomorrow

You may want to see also

They are used to clean gases emitting from the metallurgical industry, coal and power plants

Electrostatic precipitators are used to clean gases emitting from the metallurgical industry, coal and power plants. They are large industrial emission control units that are designed to trap and remove dust from exhausted gases. They are the most popular devices to control air pollution in many industrial applications.

The metallurgical industry, for instance, uses electrostatic precipitators to capture particulate matter from flue gases. The negatively charged particles attach to the positive plates and are then collected in hoppers. These precipitators have an efficiency of 99% in purifying contaminated gas.

Coal-burning electric generating plants use electrostatic precipitators to trap fine particulate matter. They are especially useful in applications where a large amount of gas needs treatment and where the use of a wet scrubber is not appropriate. The dirty gas stream passes across high-voltage wires, carrying a large negative DC voltage. The particles are then electrically charged and migrate through the electrostatic field to a grounded collection electrode.

Power plants also use electrostatic precipitators as an air pollution control system to effectively capture pollutants from exhaust gases. They are particularly useful in removing fly ash particles from the flue gases produced by coal-fired boilers.

Plastic Recycling: Air Pollution Paradox?

You may want to see also

They are not suitable for residential use due to the risk of ozone exposure

Electrostatic precipitators are devices that use electrostatic forces to remove impurities from the air. They are highly effective in industrial settings for capturing important metals and minerals from flue gases, as well as removing harmful particulate matter from waste gases at industrial facilities and power-generating stations.

However, electrostatic precipitators are not suitable for residential use due to the risk of ozone exposure. While they can collect dust, mould, and other large particles, they are less efficient than traditional air purifiers with high-efficiency air filters and strong motors. The primary concern with using electrostatic precipitators in homes is the release of ozone and nitrogen oxides, which poses health risks.

Ozone (O3), also known as smog, is a gas molecule composed of three oxygen atoms. It is harmful to the lungs and can cause inflammation and damage to the airways. The electrostatic precipitator's air-charging process produces ozone as a by-product, introducing pollution into the indoor environment. This is particularly concerning for individuals with breathing conditions such as asthma, as ozone can aggressively attack lung tissue and cause respiratory issues.

To minimise ozone production, a two-stage design can be used, which separates the charging and collecting sections. This design is often employed in shipboard engine rooms to clean the air and prevent the buildup of flammable oil fog. However, for residential air purification, traditional air filters or alternative technologies like activated carbon, fiberglass, or HEPA filters are recommended to improve indoor air quality without the risk of ozone exposure.

While electrostatic precipitators are not suitable for residential use due to ozone concerns, they remain a valuable technology for industrial air pollution control, helping to capture and remove harmful pollutants from industrial processes.

Electric Vehicles: Clean Air Revolution

You may want to see also

They are highly effective at removing particulate matter, including fine particles

Electrostatic precipitators are highly effective at removing particulate matter, including fine particles. They are commonly used to remove particles from waste gases at industrial facilities and power-generating stations. The basic mechanism involves using electrostatic force to grab and hold dust and other particles. Electrostatic precipitators consist primarily of wires and collection plates, with a high voltage applied from an electrostatic field between the wires and the collecting plate, charging the air electrically and ionizing them.

The electrostatic precipitator functions by applying energy only to the particulate matter being collected, without significantly impeding the flow of gases. The particles become charged as they flow between the collecting plates, causing them to attach to the oppositely charged plates. The air then flows through, leaving purified air. The collected particles are then removed from the plates through various methods, such as shaking, scraping, or washing, and disposed of safely.

The effectiveness of electrostatic precipitators is evident in their ability to capture fine particles, including those smaller than 2.5 microns (0.0001 inches) in diameter. Some precipitators can even remove particles as small as 0.01 microns in diameter. This capability is crucial for preventing the release of fine particles that can be drawn deep into the lungs, causing serious health issues.

Additionally, electrostatic precipitators can handle large volumes of gas at various temperatures and flow rates, making them suitable for industrial applications. They are also durable and require minimal maintenance. However, one of the limitations of electrostatic precipitators is their dependence on the electrical resistivity of particulate matter, and they may not be suitable for certain types of particles with higher electrical resistivity.

Overall, electrostatic precipitators play a vital role in air pollution control, especially in industrial settings, by effectively removing fine particulate matter and contributing to cleaner air.

Understanding Secondary Air Pollutants: Formation and Impact

You may want to see also

Electrostatic precipitators were first invented in the early 20th century by Dr. Frederick Cottrell

Electrostatic precipitators are devices that use electrostatic force to grab and hold dust and other particles from the air. They were first invented in the early 20th century by Dr. Frederick Cottrell, a chemistry professor at the University of California, Berkeley. In 1907, Dr. Cottrell applied for a patent on a device that charged particles and collected them using electrostatic attraction. The device was first used to collect sulfuric acid mist and lead oxide fumes emitted from various acid-making and smelting activities, which were harming vineyards in northern California.

At the time of Cottrell's invention, the theoretical basis for its operation was not understood. It was only later, in Germany, that Walter Deutsch and the Lurgi company developed the operational theory behind electrostatic attraction. Despite this, Cottrell's device worked, and he was able to use the profits from it to fund further research, experiments, and innovations. Cottrell's invention was originally designed for the recovery of valuable industrial-process materials, but it soon found a crucial application in air pollution control.

Electrostatic precipitators are now widely used in industrial settings to remove harmful particulate matter from waste gases, particularly in metallurgical, coal, and power plants. They are also used for capturing important metals and minerals from flue gases. The electrostatic force ionizes the particles in the flue gas, causing them to be attracted to and deposited on collection plates. The treated air then passes out of the precipitator, resulting in cleaner, purified air.

Over the years, various companies have been involved in manufacturing and improving the technology of electrostatic precipitators. These include Western Precipitation, Lodge-Cottrell, Lurgi Apparatebau-Gesellschaft, and Japanese Cottrell Corp. In 1946, anti-trust concerns forced the elimination of territory restrictions for these companies. Today, electrostatic precipitators continue to play a crucial role in air pollution control, helping to reduce the negative impact of industrial activities on the environment and human health.

Beijing's Battle Against Smog: Strategies and Successes

You may want to see also

Frequently asked questions

An electrostatic precipitator is a device that uses an electric charge to remove certain impurities from air or other gases.

An electrostatic precipitator uses electrostatic force to grab and hold dust and other particles. It consists primarily of wires and collection plates, with a high voltage applied from an electrostatic field between the wires and the collecting plate, charging the air electrically and ionizing them in the process.

An electrostatic precipitator removes fine particulate matter like ash, dust, soot, smoke, oil, grease, and other liquid droplets from the air.

Electrostatic precipitators are commonly used in industrial settings, such as power plants, factories, and other facilities that produce waste gases. They are used to remove harmful pollutants from the air before it is released into the atmosphere.

Electrostatic precipitators are not typically recommended for home use as they are not as effective as other air purification systems in removing common indoor air pollutants. Additionally, they can produce ozone and nitrogen oxides, which can be harmful to human health.