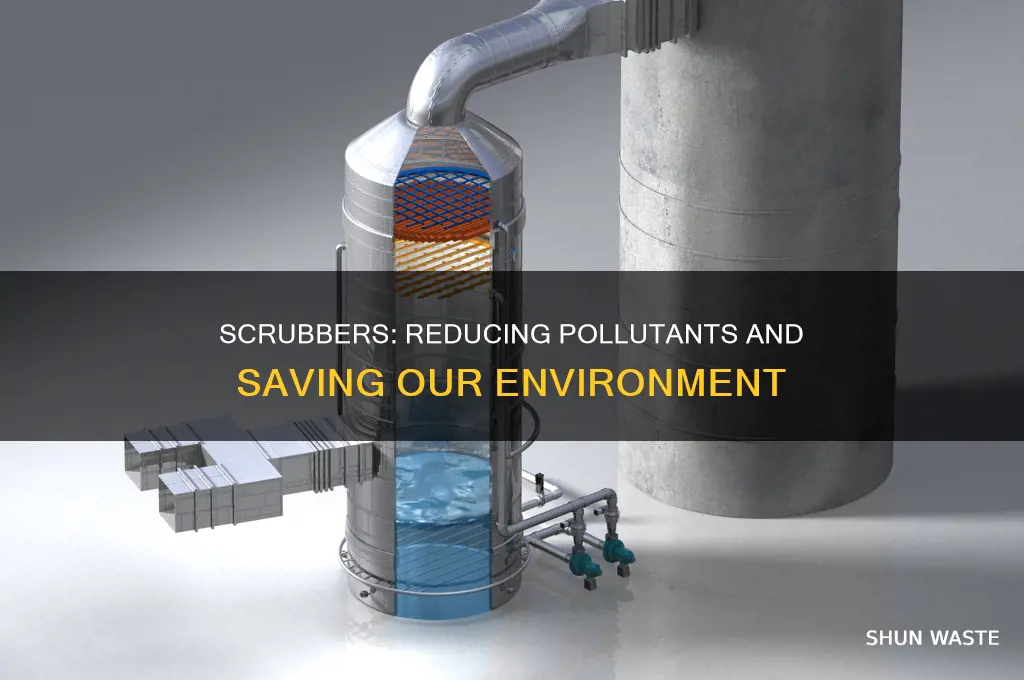

Scrubbers are devices that can be used to remove pollutants from industrial exhaust streams. They come in two main forms: wet scrubbers and dry scrubbers. Wet scrubbers use a liquid solution, usually water, to capture pollutants, while dry scrubbers use dry reagents or slurries to capture and neutralize pollutants. Wet scrubbers are effective at removing inorganic contaminants, particulate matter, and volatile organic compounds (VOCs), while dry scrubbers are commonly used to remove acid gases from combustion sources. Overall, scrubbers play a crucial role in reducing emissions and improving air quality, but they also generate toxic waste that must be properly managed to avoid further environmental harm.

| Characteristics | Values |

|---|---|

| Pollutants Removed | Inorganic fumes, vapors, gases, volatile organic compounds, particulate matter, hazardous air pollutants, sulfur dioxide, acid gases, water-soluble inorganic contaminants, foul odors |

| Efficiency | 90-98% |

| Energy Usage Levels | Low, medium, high |

| Types | Wet, dry |

| Wet Scrubber Types | Spray tower, venturi, packed bed, tray, impingement-plate, orifice, condensation, mechanically-aided |

| Dry Scrubber Types | Spray dryer absorbers, dry sorbent injectors |

| Applications | Power plants, chemical manufacturing, metal processing, pharmaceuticals, waste incineration, wastewater treatments, paper plants, steel mills, industrial fertilizer centers, boats |

What You'll Learn

Volatile Organic Compounds

Wet scrubbers are an effective way to remove VOCs from the air. Wet scrubbers use a liquid solution, usually water, to capture pollutants. The liquid interacts with the gas stream, absorbing or chemically reacting with the pollutants to remove them. The cleaned gas then exits the scrubber, while the polluted liquid is collected for further treatment or disposal.

There are several types of wet scrubbers that can be used to remove VOCs:

- Spray Towers: These scrubbers use spray nozzles to disperse liquid into the gas stream. They effectively remove larger particulates.

- Venturi Scrubbers: These scrubbers use a high-velocity gas stream to atomize the liquid, creating a fine mist that captures smaller particles and soluble gases. They are excellent for particulate removal.

- Packed Bed Scrubbers: These scrubbers contain a bed of packing material to increase the contact area between the gas and liquid. They remove gases and vapors through absorption or chemical reaction.

- Tray Scrubbers: These scrubbers use trays instead of packing material to facilitate gas-liquid contact.

Wet scrubbers are vital for removing VOCs in various industries, including chemical manufacturing, metal processing, pharmaceuticals, and waste incineration. By using wet scrubbers, industries can minimize their environmental impact, reduce potential health risks, and comply with stringent environmental regulations.

Reducing Fossil Fuel Power Station Pollution: Strategies and Innovations

You may want to see also

Hazardous Air Pollutants

Wet scrubbers are highly effective in removing HAPs from industrial exhaust streams. They use a liquid solution, usually water, to capture pollutants through absorption or chemical reactions. Venturi scrubbers, a type of wet scrubber, are particularly efficient in removing HAPs due to their ability to create a fine mist that captures smaller particles and soluble gases. Packed bed scrubbers are also effective in removing HAPs by providing a large surface area for liquid-gas interaction.

In addition to wet scrubbers, dry scrubbers can be used to remove HAPs. Dry scrubbers inject dry reagents or slurries into the exhaust stream to neutralise acid gases. Spray dryer absorbers (SDAs) are a type of dry scrubbing system that uses an alkaline slurry to absorb and neutralise acid gases, forming solid salts that can be removed easily.

The use of scrubbers, both wet and dry, plays a crucial role in reducing the environmental and health impacts of HAPs. By removing these toxic substances from industrial exhaust streams, scrubbers help improve air quality, protect ecosystems, and safeguard public health.

Solar Power: Clean Energy, Clear Skies

You may want to see also

Particulate Matter

The sources and hazard levels of particulate matter can vary. Some particulate matter can cause health issues if inhaled, and if small enough, they can enter the bloodstream. In large quantities, particulate matter can reduce visibility and cause haziness in the atmosphere. Due to these negative effects, regulating the quantity of particulate matter is crucial for maintaining air quality.

Scrubbers, particularly wet scrubbers, are effective in removing particulate matter from industrial exhaust streams. Wet scrubbers use a liquid solution, usually water, to capture pollutants. The liquid interacts with the gas stream, either by absorption or through a chemical reaction, thereby removing the pollutants.

There are several types of wet scrubbers, each with its own design to optimise the removal of particulate matter:

- Spray towers use spray nozzles to disperse liquid into the gas stream, effectively removing larger particulates.

- Venturi scrubbers use a high-velocity gas stream to create a fine mist that captures smaller particles efficiently.

- Packed bed scrubbers employ a bed of packing material to increase the contact area between the gas and liquid, facilitating the removal of gases and vapours.

- Tray scrubbers utilise trays instead of packing material to facilitate gas-liquid contact and remove pollutants.

Wet scrubbers can achieve a high level of particulate matter removal, with most wet scrubbing systems operating with particulate collection efficiencies of over 95%. There are three energy usage levels for wet scrubbers: low, medium, and high energy. The energy level required depends on the size of the particulate matter, with high-energy scrubbers capable of removing sub-micrometre particles.

In summary, scrubbers, especially wet scrubbers, play a crucial role in reducing particulate matter emissions from industrial processes. By utilising various designs and energy levels, wet scrubbers can efficiently capture and remove particulate matter, contributing to improved air quality and reducing potential health risks associated with inhaling or exposure to particulate matter.

Green Revolution: Reducing Environmental Pollution

You may want to see also

Acid Gases

Wet scrubbers use a liquid solution, usually water, to capture pollutants. The liquid interacts with the gas stream, absorbing or chemically reacting with the pollutants to remove them. The scrubbing liquid absorbs the pollutants or reacts with them to form a less harmful compound. The cleaned gas then exits the scrubber, while the polluted liquid is collected for further treatment or disposal.

Wet scrubbers can remove acid gases such as hydrochloric acid (HCl) and ammonia (NH3) very effectively. They are also used to remove sulfur dioxide (SO2) and other acid gases from flue gases in power plants. Additionally, dry scrubbers, which use dry reagents instead of liquid solutions, are also effective at removing acid gases. Dry sorbent injectors (DSIs) and spray dryer absorbers (SDAs) are two types of dry scrubbing systems that can be used to remove acid gases from combustion sources.

The use of scrubbers to reduce acid gases has several benefits. Firstly, it helps industries comply with stringent environmental regulations by reducing emissions of harmful substances. Secondly, by removing pollutants from exhaust streams, scrubbers contribute to improved air quality and public health. Lastly, scrubbers can also be used for heat recovery from hot gases, which can be beneficial for energy utilization.

Reducing Plastic Pollution: Practical Steps for a Greener Tomorrow

You may want to see also

Water-Soluble Inorganic Contaminants

Wet scrubbers are particularly effective in removing water-soluble inorganic contaminants, which can include toxic and corrosive gases such as hydrochloric acid (HCl) and ammonia (NH3). These contaminants are often generated in industrial processes and can pose significant risks to both environmental and human health if released into the atmosphere.

The wet scrubbing process involves passing the contaminated gas stream through a scrubbing liquid, typically water, which absorbs or chemically reacts with the pollutants. Wet scrubbers utilize a large surface area, created by packing materials or spray nozzles, to maximize contact between the liquid and gas stream. This process results in the absorption and removal of the water-soluble inorganic contaminants.

Wet scrubbers offer a high level of removal efficiency for these contaminants, with most systems achieving efficiencies above 90%. The efficiency is influenced by factors such as the energy expended, the liquid flow rate, and the gas flow rate.

By employing wet scrubbers, industries can significantly reduce the emission of water-soluble inorganic contaminants, contributing to improved air quality, environmental sustainability, and compliance with stringent environmental regulations.

Ganesh Chaturthi: Reducing Noise Pollution for a Peaceful Festival

You may want to see also

Frequently asked questions

A scrubber is an air pollution control device that removes unwanted pollutants from a gas stream. There are two main types of scrubbers: wet scrubbers, which use a liquid solution to capture pollutants, and dry scrubbers, which use dry reagents.

Wet scrubbers use a liquid, usually water, to absorb or chemically react with pollutants. Dry scrubbers use dry sorbent materials that react with pollutants to form solid compounds, which are then separated from the gas stream.

Scrubbers can remove a wide range of pollutants, including particulate matter, gases, and vapors. Wet scrubbers are particularly effective at removing inorganic contaminants, while dry scrubbers are commonly used to remove acid gases.

Scrubbers offer high efficiency in removing pollutants and are versatile across various industrial applications. They help industries comply with stringent environmental regulations and improve air quality and public health.

Scrubbers can present challenges such as clogging, corrosion, high energy consumption, and waste disposal. Poor waste management of scrubber byproducts can lead to environmental issues, and not all industrial plants utilize scrubber technology due to the associated costs.