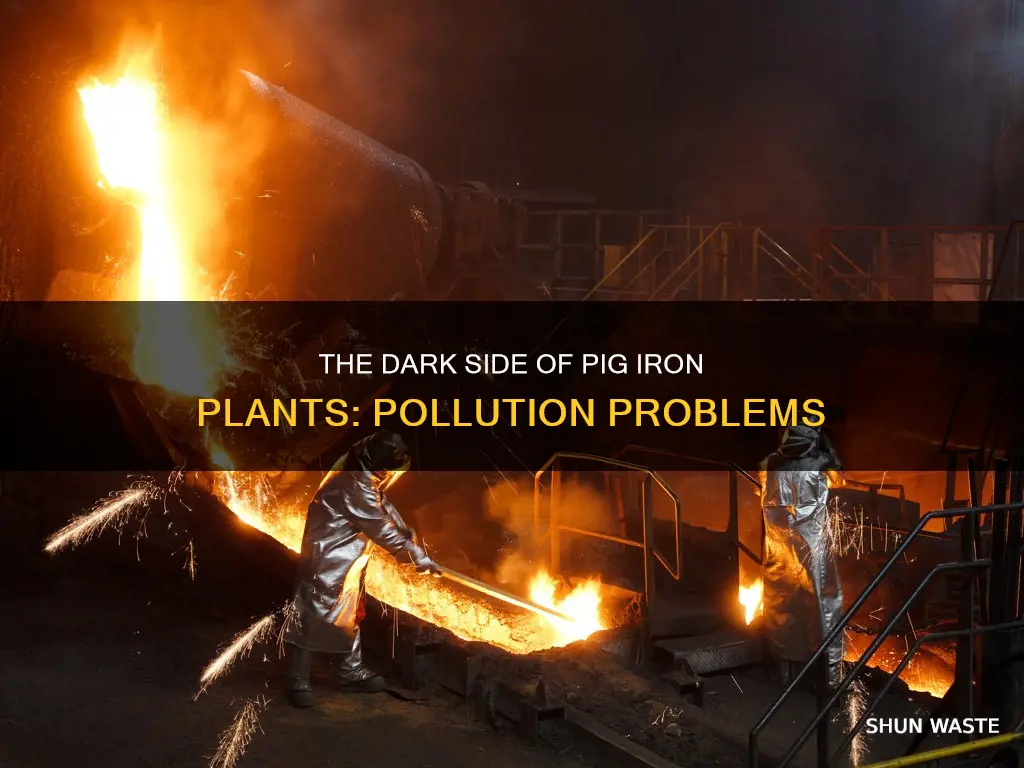

The production of pig iron has been associated with environmental concerns, particularly in the context of coal and steel production. The process requires cheap coking coal and electricity, which can contribute to air and water pollution through emissions and waste. While steel production is a significant source of greenhouse gas emissions, the environmental impact of pig iron plants specifically has been a subject of debate, with experts asserting that adherence to protocols can mitigate potential issues. However, the history of pollution in certain areas, such as Ashtabula, Ohio, has left residents concerned about the potential impact of new pig iron plants.

| Characteristics | Values |

|---|---|

| Air emissions | CO, SOx, NOx, PM2, CO2, coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur, coke dust |

| Water emissions | Nitrogen, phosphorus, nitrates, ammonia, pathogens, pharmaceuticals, heavy metals |

| Solid waste | Slag, limestone, iron ore impurities |

| Greenhouse gas emissions | 6.5% of global CO2 emissions are derived from iron and steel production |

| Water usage | Large volumes of water are used to cool coke |

| Energy consumption | High energy consumption leads to carbon dioxide emissions |

| Coal usage | Coal plants produce high levels of pollution |

Air emissions

The environmental impact of pig farming, an integral part of the pig iron supply chain, also contributes to air pollution. Pig waste contains pathogens, bacteria (often antibiotic-resistant), and heavy metals that can pollute the air and cause respiratory ailments and increased stress among nearby communities. Intensive pig farming has been linked to smog and air pollution in certain regions, and the waste from these farms can lead to widespread pollution within the watershed.

Furthermore, the process of producing pig iron requires cheap coking coal and electricity, which can have environmental implications. The Chinese government's efforts to shut down high-pollution coal plants may eventually impact pig iron producers, forcing them to adopt cleaner technologies.

To mitigate air emissions, filtration methods can be employed to remove most pollutants. Additionally, sulfur dioxide and hydrogen sulfide can be captured using air emissions control equipment, preventing their release into the atmosphere. While these measures do not prevent pollution entirely, they help reduce the environmental impact of pig iron production.

Overall, the production of pig iron and its upstream supply chain, including pig farming, can contribute to air pollution through various emissions and waste by-products. However, with proper protocols and regulations in place, these environmental concerns can be addressed to ensure a more sustainable and cleaner production process.

Urban Overcrowding: A Major Driver of Pollution Crises

You may want to see also

Water contamination

Today, iron contamination in water is primarily associated with groundwater, such as wells and springs, where iron is the most common dissolved chemical. This is due to the natural occurrence of iron in the surrounding soil and rocks, which can leach into the water. While iron is not considered a significant health hazard, it can cause unpleasant issues, such as discolouration of water, taste and odour problems, and staining of laundry and household fixtures. Additionally, chronic exposure to high iron levels has been linked to health issues like gastrointestinal distress and iron overload.

Pig iron plants and intensive pig farming practices have been identified as contributors to water contamination, particularly through the improper disposal of pig manure and the lack of waste treatment facilities. Heavy metals, such as copper (Cu), zinc (Zn), and cadmium (Cd), are commonly used as feed additives in pig farming to promote growth and prevent infections. These metals can accumulate in the soil and leach into groundwater, posing potential threats to ecosystems and human health. Studies have found elevated levels of these heavy metals in the environment surrounding pig farms, indicating the risk of water contamination.

To address iron and heavy metal contamination in water, various treatment technologies have been developed. These include advanced oxidation-filtration systems, electrocoagulation (EC) cells, and community-based iron removal plants that use sand and manganese dioxide filtration. Additionally, initiatives such as stricter management of feed additives and waste discharge in pig farming are crucial to mitigate the risk of water contamination.

Yamuna's Froth: India's Pollution Crisis

You may want to see also

Greenhouse gas emissions

The production of pig iron is energy-intensive, requiring large amounts of cheap coking coal and electricity, which can lead to high carbon dioxide emissions. According to the IEA in 2010, 6.5% of global CO2 emissions are derived from iron and steel production. The carbon dioxide emissions from energy consumption are the primary source of greenhouse gases in steel production, with coke production being a major contributor. Coke is produced by heating coal in an oven, and the process releases air emissions such as coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur, and coke dust. These emissions contribute to the overall carbon footprint of pig iron plants.

Additionally, the water used to cool coke after baking becomes contaminated with coke breezes and other compounds, leading to water emissions. While the contaminated water can be reused fairly easily, it still contributes to the overall environmental impact of the pig iron plant.

To address these environmental concerns, regulations and protocols have been put in place by organizations like the EPA to ensure that pig iron plants operate within certain standards. By following these protocols, the potential impact on the environment can be minimized.

Furthermore, the development of cleaner technologies and processes is crucial for reducing greenhouse gas emissions in the pig iron industry. For example, the Chinese government's move to shut down high-pollution coal plants may eventually extend to pig iron producers, forcing them to adopt more sustainable practices and technologies.

In conclusion, greenhouse gas emissions are a significant environmental challenge for pig iron plants, but with proper regulations, improved technology, and a shift towards cleaner production methods, the industry can reduce its carbon footprint and mitigate its impact on the planet.

Climate Change: Pollution's Impact and Influence

You may want to see also

Solid waste

One type of solid waste produced during the creation of pig iron is slag. Slag is a by-product of the smelting process, formed by the melting of impurities from iron ore after the addition of molten materials such as limestone, dolomite, and coke ash. In the past, slag was considered waste, but due to intensive re-utilisation, it is now referred to as a by-product.

Another source of solid waste in the pig iron production process is crushing plant waste. The production of pig iron often involves using a hot blast cupola (HBC) furnace, which is injected with charcoal powder to improve the temperature and reduction zone in the furnace. The raw material undergoes a washing process and magnetic separation to improve the iron content degree from the crushing plant waste.

Additionally, the mining of iron ore, a crucial component in pig iron production, generates significant amounts of solid waste in the form of waste rock and tailings. Tailings are the waste material left over from the ore processing phase, often containing toxins and heavy metals that can lead to dangerous runoff and water contamination if not properly stored or disposed of.

To address the solid waste generated by the steel industry, companies have implemented various waste disposal methods and recycling initiatives. For example, Tangshan Iron & Steel, the flagship site of China's largest steelmaker, invested in plant energy savings and emission reduction technology, significantly reducing dust and sulfur dioxide emissions. They also signed a joint venture agreement with Harsco for the environmentally beneficial handling and processing of steelmaking by-products, including advanced slag treatment processes.

Recycling is a crucial component of modern waste reduction strategies, and companies like Schnitzer Steel Industries Inc. have specialised in recycling scrap metal and manufacturing finished steel products. Recycling helps prevent the waste of useful materials, reduces energy usage, mitigates air and water pollution, and lowers greenhouse gas emissions.

Light Pollution's Dark Side: Obesity's Surprising Cause

You may want to see also

Acid rain

The production of pig iron is resource-intensive and has been associated with high levels of pollution. While pig iron plants do not directly cause acid rain, the process of producing pig iron can contribute to air and water pollution, which are the main causes of acid rain.

The ecological effects of acid rain are most evident in aquatic environments such as streams, lakes, and marshes, where it can harm fish and other wildlife. Acid rain can also impact soil composition by stripping it of essential nutrients like calcium and magnesium, which are crucial for plant growth and maintaining healthy soil. This, in turn, affects the plants and animals that depend on these nutrients.

Additionally, acid rain increases the corrosion rate of metals, particularly iron, steel, copper, and bronze. It causes paint to peel, corrodes steel structures like bridges, and accelerates the weathering of stone buildings and statues.

To mitigate the problem of acid rain, governments in Europe and North America have implemented regulations to reduce the release of sulfur dioxide and nitrogen oxide into the atmosphere. These efforts have had positive outcomes, with acid rain levels dropping significantly since the 1970s.

Air Pollution in India and China: What's Causing It?

You may want to see also

Frequently asked questions

A pig iron plant is a plant that produces pig iron, which is an intermediate good used by the iron industry in the production of steel.

The production of pig iron can cause air and water pollution. Air emissions such as CO, SOx, NOx, PM2, coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur, and coke dust are released from coke ovens. Water emissions also occur from the water used to cool coke after it has been baked.

The environmental impacts of pig iron production include an increase in greenhouse gas emissions, specifically carbon dioxide emissions related to energy consumption.

The potential risks associated with the pollution caused by pig iron plants include water contamination and gas emissions, which can lead to respiratory ailments, increased stress, decreased quality of life, and higher blood pressure in nearby communities.