Stack emission testing is a crucial process for monitoring and controlling industrial emissions. It involves measuring and analysing the levels of air pollutants emitted from industrial sources, such as chimneys, boilers, and furnaces. The primary objective of stack emission testing is to ensure compliance with regulatory standards, evaluate the efficiency of pollution control equipment, and minimise the environmental impact of industrial activities. By conducting these tests, industries can identify and mitigate the release of harmful pollutants, such as carbon monoxide, methane gas, and nitrogen oxide, into the atmosphere. Stack monitoring is an important tool for facility managers to assess the level of industrial waste emitted and ensure that emission levels remain within acceptable parameters.

| Characteristics | Values |

|---|---|

| Definition | A stack is a chimney that disperses hot air, emissions, and particulate matter at a great height. |

| Pollutants | Solid, liquid, gaseous, organic, and inorganic substances. |

| Examples of Stacks | Boiler, flue gas, DG set, DG exhaust pipe, furnace, and chimney. |

| Stack Emission Monitoring | A process to identify harmful exhaust gases and measure the level of industrial waste emitted from stacks. |

| Benefits of Continuous Monitoring | Real-time data, improved compliance, and quick identification of emission issues. |

| Testing Methods | In-situ measurement, extractive dilution, capture of emissions at the source, and specialized equipment for pollutant concentrations, flow rates, temperature, and velocity. |

| Pollutants Monitored | Carbon Monoxide (CO), Methane Gas (CH4), oxides of Sulphur (SOx), Nitrogen (NOx), hydrocarbon compounds, and particulate matter. |

| Regulatory Bodies | Central Pollution Control Board (CPCB) in India, U.S. EPA Air Pollution Institute, and others. |

| Regulatory Standards | Federal Clean Air Act (CAA), state regulations, and air quality standards for specific pollutants. |

| Environmental Impact | Stack emission testing helps industries minimize environmental impact, comply with regulations, and safeguard human health. |

What You'll Learn

Stack emission monitoring

A stack is a chimney that disperses hot air, emissions, and particulate matter at a great height. The height of the stack plays a crucial role in determining the dispersion of pollutants in the upper level of the air. The pollutants emitted from the stack can be solid, liquid, gaseous, or particulate matter that can be organic or inorganic.

There are several methods and systems used for stack emission monitoring. Continuous Emission Monitoring Systems (CEMS) are commonly used to collect real-time data on various parameters such as O2, CO2, CO, NOx, SO2, and THC. These systems help industries report fewer compliance issues and make data-driven decisions that improve efficiency and long-term environmental sustainability.

In addition to CEMS, stack emission testing is also employed, which includes capturing emissions at the source using sample collection devices and analyzing them in a certified laboratory. This type of testing can be complex and requires extensive preparation and a competent test team. Organizations such as Perfect Pollucon Services, MAC Instruments, and Pace Analytical offer stack emission monitoring services and equipment to help industries meet regulatory requirements and environmental sustainability goals.

Overall, stack emission monitoring is a critical tool for industries to assess their compliance with emission regulations, improve their environmental performance, and reduce potential impacts on public health and the environment.

Breathing Polluted Air: A Silent Smoking Hazard

You may want to see also

Air quality standards

A stack, in the context of air pollution, is a chimney that disperses hot air, emissions, and particulate matter at a great height. The height of the stack plays a crucial role in determining the dispersion of pollutants. The pollutants emitted from the stack can be solid, liquid, or gaseous organic or inorganic substances.

National Ambient Air Quality Standards (NAAQS)

The Clean Air Act, last amended in 1990, mandates the EPA to establish National Ambient Air Quality Standards (NAAQS) for six principal pollutants, also known as "criteria pollutants." These pollutants, which include SO2, NO2, CO, O3, hydrocarbons, and particulate matter, are common in outdoor air and are considered harmful to public health and the environment. NAAQS are reviewed and revised periodically to ensure their effectiveness.

Primary and Secondary Standards

NAAQS are divided into two types: primary and secondary standards. Primary standards focus on protecting public health, especially sensitive populations such as asthmatics, children, and the elderly. On the other hand, secondary standards aim to safeguard the public welfare, including protection against damage to crops, vegetation, buildings, and visibility.

Air Quality Index (AQI)

The EPA also developed the Air Quality Index (AQI), which is a scale that ranges from 0 to 500. The AQI provides a clear indication of air quality, with lower values representing good air quality and higher values indicating hazardous levels. This index helps the public understand the level of air pollution and potential health risks associated with it.

Emission Monitoring and Compliance

To ensure compliance with air quality standards, organisations such as Perfect Pollucon Services and Machine Applications Corporation offer stack emission monitoring services. These services help industries measure and control the level of industrial waste and pollutants emitted from stacks. Continuous Emission Monitoring Systems (CEMS) are recommended as they provide real-time data, enabling facility managers to quickly address any emission level deviations.

Regulatory Enforcement

Failure to meet air quality standards can result in legal penalties and fines for offending companies. Regulatory bodies, such as the EPA and CPCB, enforce these standards through periodic testing, emission control system design, and the implementation of monitoring systems. Their efforts help industries meet legal requirements and promote environmental sustainability.

Air Pollution: What Traps It in Place?

You may want to see also

Environmental compliance

A stack is a chimney that disperses hot air, emissions, and particulate matter at a great height. The height of the stack plays a crucial role in determining the dispersion of pollutants in the upper level of the air. The pollutants emitted from the stack can be solid, liquid, gaseous, or organic/inorganic.

Regulatory Framework

Many countries have implemented comprehensive air pollution control acts, such as the Clean Air Act (CAA) in the United States, to establish standards and guidelines for air quality. These acts outline the responsibilities of government agencies, such as the Environmental Protection Agency (EPA), in enforcing air quality standards and regulating emissions from various sources, including industrial facilities, power plants, and vehicles.

Emission Monitoring and Testing

Emission monitoring and testing is a critical aspect of environmental compliance. Companies are often required to conduct regular emission testing to ensure that they meet the prescribed standards for particulate matter, gases, and other pollutants. Continuous Emission Monitoring Systems (CEMS) are recommended as they provide real-time data, helping facility managers quickly identify and remedy excessive emission levels. Stack emission monitoring is particularly important for power plants and industrial facilities to measure the level of industrial waste and equipment efficiency.

Compliance Requirements for Businesses

Small and large businesses must comply with air quality regulations, which may vary by state or region. They may be required to identify and calculate their emission potentials and determine if specific emissions require an air permit. Regulatory bodies provide compliance resources and assistance programs to help businesses navigate the complex process of emission calculation and permitting.

Pollution Control Systems

To achieve environmental compliance, companies must implement effective pollution control systems. This includes the use of technologies such as settling chambers, cyclone separators, wet scrubbers, fabric filtration, and electrostatic precipitation to capture and control particulate and gaseous emissions. These systems help reduce the release of harmful pollutants, such as SOx, NOx, CO, and particulate matter, into the atmosphere.

Enforcement and Penalties

Environmental protection agencies have the authority to enforce compliance with air pollution regulations. They can inspect facilities, investigate suspected sources of air pollution, and take appropriate action for non-compliance. This may include refusing to issue or revoking permits, imposing fines, or requiring the implementation of corrective measures to reduce emissions and mitigate environmental impacts.

Overall, environmental compliance in the context of air pollution involves strict adherence to regulations, regular emission monitoring and testing, the implementation of effective pollution control systems, and collaboration with regulatory bodies to ensure the protection of human health and the environment.

Boston's Air Pollution: Key Causes and Concerns

You may want to see also

Industrial sources

Industrial facilities often discharge pollutants into the atmosphere through smokestacks or industrial flues. These pollutants include carbon monoxide, methane, oxides of sulphur, nitrogen, and hydrocarbon compounds. The height of these stacks plays a crucial role in determining the dispersion of pollutants into the upper levels of the atmosphere. At greater heights, the polluted air disperses over a larger area, ensuring that concentrations at ground level are within permissible limits and are not harmful to humans, animals, and vegetation.

Stack emission monitoring is a critical requirement for industrial air pollution control. It involves measuring the quality and quantity of air pollutants emitted by the source, typically through gas analyzers installed at the exhaust point. This process helps industries comply with environmental regulations and avoid legal penalties. For example, in India, the Central Pollution Control Board (CPCB) is responsible for regulating emission standards for industries.

Companies such as Perfect Pollucon Services and Federated Environmental offer stack emissions testing and control design installation. These services help industries achieve accurate emission measurements, proper data reporting, and compliance with environmental regulations. By addressing these challenges, industries can avoid fines, improve environmental performance, and ensure sustainable operations.

Federated Environmental, in particular, has the expertise to test emissions, provide facility status explanations, and offer recommendations to avoid "non-attainment" criteria under state regulations. They can also design new systems or modify current emission systems and install monitoring systems on existing stacks. Their services extend to design support for new facilities as well.

Understanding Non-Point Sources of Air Pollution

You may want to see also

Pollutant identification

Stack emission monitoring is a critical aspect of pollutant identification and control in industrial settings. A stack, or chimney, is used to disperse hot air, emissions, and particulate matter at a significant height, ensuring that the polluted air disperses over a large area and that ground-level concentrations are within permissible limits.

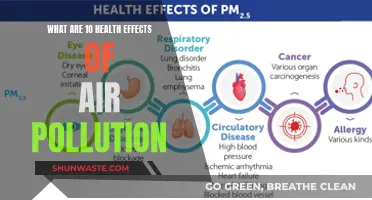

The pollutants emitted from stacks can vary, including solid, gaseous, liquid organic, or inorganic substances. These emissions are the result of the combination, decomposition, or combustion of materials. Some common air pollutants include:

- Radon gas

- SOx

- NOx

- CO

- O3

- Hydrocarbons

- Particulate matter (PM)

To effectively identify and manage these pollutants, industries employ Continuous Emission Monitoring Systems (CEMS). These systems provide real-time data on emission levels, enabling facility managers to ensure compliance with air quality standards and quickly address any deviations.

In addition to real-time monitoring, pollutant identification also involves regular stack emission testing. This testing involves capturing emissions at the source using sample collection devices and analyzing them in certified laboratories. The testing procedures are designed to assess a range of parameters, including total suspended particles, particle size distribution, and the presence of specific pollutants.

By combining continuous monitoring and periodic testing, industries can accurately identify the types and levels of pollutants emitted from stacks and implement effective control measures to reduce their environmental impact and comply with regulatory requirements.

Chicago's Air Pollution: What's Behind the Smog?

You may want to see also

Frequently asked questions

A stack, in the context of air pollution, refers to the long height chimneys in industries that emit or diffuse hot gases and pollutants at a safe height so that it doesn't harm the surrounding area.

The major pollutants emitted by stacks include carbon monoxide (CO), methane gas (CH4), oxides of sulphur (SOx), nitrogen (NOx), and hydrocarbon compounds.

Stack emission monitoring is important to ensure environmental compliance and to monitor the quality of air emissions from industrial sources. By conducting these tests, industries can identify and mitigate the release of harmful pollutants into the atmosphere.

Continuous stack emission monitoring provides real-time data that enables facility managers to keep emissions within acceptable parameters. It also helps industries meet regulatory approval and environmental responsibility by reducing air pollution penalties and operational shutdown risks.