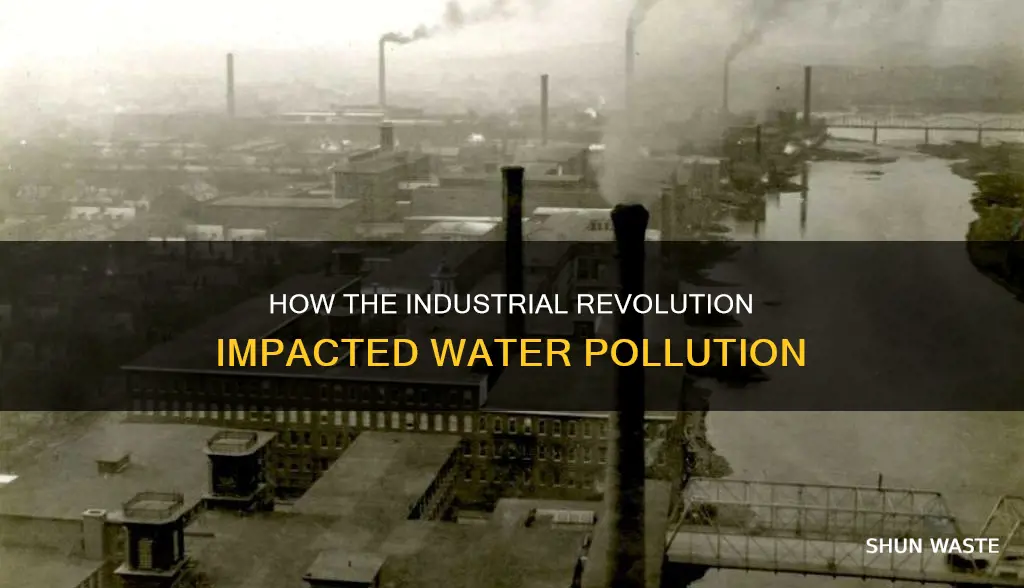

The Industrial Revolution, which occurred between the late 18th and early 20th centuries, marked a period of rapid economic growth and technological advancement. However, it also introduced new sources of pollution, particularly air pollution and water pollution, which have had profound and lasting impacts on the environment. While the effects of air pollution were more immediately apparent, with smog and soot causing serious health issues in growing urban centres, water pollution was also a significant issue. During this time, industrial corporations and cities began using waterways to dump waste, including sewage, oil, debris, and other harmful pollutants, leading to contaminated water sources and widespread loss of wildlife.

Was any polluted water avoided during the Industrial Revolution?

| Characteristics | Values |

|---|---|

| Water Pollution | Significantly worsened during the Industrial Revolution, with factories dumping pollutants directly into rivers and streams |

| Environmental Impact | The Industrial Revolution marked the start of intensive fossil fuel use, leading to large-scale carbon emissions and climate change |

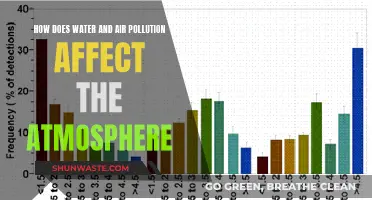

| Air Pollution | The use of coal during the Industrial Revolution caused smog and soot, resulting in serious health issues for residents of urban areas |

| Health Impact | Industrial air and water pollution contributed to disease epidemics and health issues such as asphyxiation and respiratory problems |

| Legislative Response | Efforts to control pollution emerged in the 1960s, leading to legislation like the Clean Air Act (1970) and Clean Water Act (1972) |

| Current Status | Water quality in British rivers has improved in urban areas but declined in rural areas since the Industrial Revolution |

| Transition to Renewable Energy | Global efforts are being made to transition from fossil fuels to renewable energy sources like wind, solar, and hydroelectric power |

What You'll Learn

- The Industrial Revolution introduced new sources of water pollution

- Waterways were used to dispose of untreated sewage waste

- Water-powered mills and factories altered people's relationship with nature

- The cotton and chemical industries increased pollution loads to rivers

- The Clean Water Act was passed in 1972 to combat water pollution

The Industrial Revolution introduced new sources of water pollution

The Industrial Revolution, a period of rapid economic growth and manufacturing-based economic advancement, introduced new sources of water pollution. The shift to manufacturing-based economies and the use of heavy industrial machinery to improve efficiency and output resulted in increased water pollution. As industrial corporations used waterways to generate power, they also utilised them as dumping grounds for waste. This waste included millions of gallons of chemical, cotton, and domestic effluent waste, which mixed with raw sewage, severely impacting the health of those living in nearby areas.

The Industrial Revolution, particularly the second phase in the late 19th to early 20th centuries, witnessed the introduction of electricity, steel production, and the internal combustion engine. This phase drove mass production and the growth of heavy industries, leading to exponential increases in energy consumption and resource extraction. The reliance on fossil fuels, such as coal, resulted in a sharp increase in carbon emissions and harmful environmental pollution, including water pollution.

During the 19th century, cities expanded rapidly to accommodate the growing workforce needed for factories, and these urban centres became heavily industrialised and polluted. The increased population density, coupled with inadequate waste treatment, further contributed to water pollution. Rivers and streams became open sewers, with corporations and municipalities disposing of untreated sewage and industrial waste into them. This waste contained harmful substances such as heavy metals, solvents, toxic sludge, and hormone-like compounds, which contaminated water sources and negatively impacted the environment and human health.

The effects of water pollution from the Industrial Revolution were far-reaching and long-lasting. Even with legislative efforts to control pollution, such as the Clean Water Act, and advancements in renewable energy sources, the consequences are still felt today. Water quality in British rivers, for example, has changed substantially since the Industrial Revolution, with urban areas showing improvements but rural areas experiencing declines. The Industrial Revolution's legacy of water pollution serves as a reminder of the importance of adapting to new challenges and implementing measures to protect and improve water quality.

Are Oni Lavatories Polluting Our Waterways?

You may want to see also

Waterways were used to dispose of untreated sewage waste

The Industrial Revolution brought about significant advancements in society, including economic growth, increased production and efficiency, improved transportation systems, and better working and living conditions. However, these advancements came at a cost, as the Revolution also marked the beginning of our intensive use of fossil fuels, which has had a profound impact on the environment and contributed to climate change.

Waterways were a convenient means of waste disposal during the Industrial Revolution, with manufacturers dumping millions of gallons of untreated sewage waste into rivers and streams. This practice, combined with the use of waterways as open sewers by rapidly growing cities, led to severe pollution and public health issues. The mixing of industrial waste and raw municipal sewage in waterways worsened disease epidemics, with water-borne illnesses such as cholera and typhoid posing a significant risk to the population.

The issue of polluted waterways was recognised as a problem, and some attempts were made to address it. For example, in 1878, the state of Massachusetts passed a pollution control law. However, these efforts were often hindered by corporations, who filed lawsuits and lobbied for weaker enforcement of the laws. Additionally, the rapid industrialisation and urbanisation of the time meant that even the strongest legislation had significant gaps and exceptions for heavily industrialised and urbanised areas.

The pollution of waterways during the Industrial Revolution had lasting impacts. It altered people's relationship with nature, particularly for those recruited from the countryside to work in the mills and factories. The environmental movement of the 1960s emerged in response to the growing awareness of the negative consequences of industrial pollution on the planet's ecosystems. This movement led to legislative victories such as the Clean Water Act in 1972, which aimed to protect waterways from pollution.

Bottled Water Manufacturing: A Pollution Conundrum?

You may want to see also

Water-powered mills and factories altered people's relationship with nature

The Industrial Revolution brought about a manufacturing-based economy, leading to advancements in production, efficiency, transportation, and working and living conditions. However, these developments had severe environmental consequences, including the start of our intensive use of fossil fuels, which continue to drive climate change.

Before the Industrial Revolution, from the time the Puritans settled in New England in the 17th century until the decades following the American Revolution, the region's landscape was dotted with small mills that used water power to meet the needs of local communities. These water-powered mills sawed wood, ground grain, and carded wool. During the Industrial Revolution, corporate investors established larger mills and factories that harnessed water power to produce goods for markets near and far. These new enterprises relied on permanent dams to make large mill ponds that fed turbines and intricate belt systems.

The shift to water-powered mills and factories significantly altered people's relationship with nature. For example, many of the first operatives recruited to work in the mills were young women from the countryside. These "mill girls" were drawn by the comparatively high wages, relative independence, and lively culture of the bustling cities. In their time off, some organized study circles and wrote poetry, stories, and essays that they published in literary journals. Within a few decades, mill girls began to agitate for better wages and working conditions, and some even crafted pieces for radical labor newspapers.

However, the Industrial Revolution also led to increased water pollution as factories began releasing pollutants directly into rivers and streams. By the late 1800s and early 1900s, the effects of this pollution were becoming apparent, with incidents such as the Cuyahoga River in Ohio catching fire in 1969 due to chemical waste. Today, efforts are being made to transition away from fossil fuels and towards renewable energy sources, and adaptation strategies are being implemented to protect communities from the impacts of climate change.

Waterway Pollution: Sources and Entry Points

You may want to see also

The cotton and chemical industries increased pollution loads to rivers

The Industrial Revolution brought about a manufacturing system based on heavy industrial machinery, which led to mass production and economic growth. However, this progress came at a cost to the environment, with the advent of new sources of air and water pollution. Factories began releasing pollutants directly into rivers and streams, with industrial corporations using waterways not only for power but also to dump waste. This resulted in the contamination of water sources, with harmful chemicals and toxins being released into the water supply.

The cotton industry, in particular, has been a major contributor to water pollution. Cotton production requires large amounts of water, and the use of pesticides, fertilizers, and other chemicals further pollutes the water. The runoff from cotton fields contaminates rivers, lakes, and groundwater, posing threats to local ecosystems and human health. The fashion industry, which relies heavily on cotton, is responsible for up to one-fifth of industrial water pollution, with wastewater being dumped directly into rivers and streams.

The chemical industry has also played a significant role in increasing pollution loads to rivers. Chemical waste released into waterways can have devastating effects, as seen in the case of the Cuyahoga River in Ohio, which caught fire in 1969 due to industrial pollution. The release of human-produced sulfur and nitrogen compounds into the atmosphere during the Industrial Revolution negatively impacted water sources, in addition to the air.

The impact of these industries on water pollution has been felt globally, with developing nations bearing a significant brunt. In China, around 70% of lakes and rivers are now polluted from industrial waste, leaving millions of people without access to clean water. Similarly, in Bangladesh, residents living along the Savar River feel helpless to stop factories from polluting their water sources. The problem is exacerbated by weak regulation and enforcement in these countries, allowing industrial operations to continue dumping untreated wastewater into waterways.

While some efforts have been made to address water pollution, such as the Clean Water Act in the United States, the challenges posed by industrialization and economic growth continue to strain water resources. The cotton and chemical industries, in particular, have contributed significantly to the pollution loads in rivers, with the effects being felt by both the environment and human populations dependent on these water sources.

GB vs US: Water Pollution Comparison

You may want to see also

The Clean Water Act was passed in 1972 to combat water pollution

The Industrial Revolution, marked by the advent of manufacturing based on heavy industrial machinery, led to rapid economic growth and advancements in transportation systems. However, it also had a profound environmental impact, intensifying water pollution as factories began releasing pollutants directly into rivers and streams. This resulted in severe consequences, such as the Cuyahoga River in Ohio catching fire due to oil and debris pollution in 1969.

To address the growing water pollution crisis, the Clean Water Act (CWA) was passed in 1972, establishing a nationwide approach to improving the quality of lakes, rivers, streams, and other water bodies in the United States. The CWA built upon the Federal Water Pollution Control Act of 1948, which was the first major US law to address water pollution. The 1972 amendments significantly reorganized and expanded the earlier act, giving it its common name, the Clean Water Act.

The Clean Water Act established a basic structure for regulating pollutant discharges into US waters and set quality standards for surface waters. It made it unlawful for any person or entity to discharge pollutants from a point source into navigable waters without obtaining a permit. The Environmental Protection Agency (EPA) was tasked with implementing pollution control programs, setting wastewater standards for industries, and developing national water quality criteria.

While the Clean Water Act has helped improve water quality over the years, threats to water safety remain. Emerging challenges, such as stormwater runoff carrying pollutants into water bodies, require further action. Additionally, there have been instances of non-compliance with the Act, highlighting the need for stronger enforcement and improvements in identifying and reducing illegal discharges.

To enhance the effectiveness of the Clean Water Act, subsequent amendments have been made. For example, revisions in 1981 streamlined the municipal construction grants process, and changes in 1987 introduced the Clean Water State Revolving Fund to address water quality needs through EPA-state partnerships. Despite these efforts, more action may be needed to strengthen the Act and meet its original goals.

Water Pollution: Sources and Human Impact

You may want to see also

Frequently asked questions

The Industrial Revolution had a profound impact on the environment, marking the start of our intensive use of fossil fuels and contributing to climate change. It led to an increase in carbon emissions, air pollution, water pollution, deforestation, and the depletion of natural resources.

During the Industrial Revolution, factories released pollutants directly into rivers and streams. Cities also disposed of untreated sewage waste into local waterways. This led to an increase in waterborne diseases and illness outbreaks.

Yes, some local and state governments tried to address water pollution by creating boards of health and passing pollution control laws. For example, in 1878, the state of Massachusetts passed a pioneering pollution control law. However, these efforts were often limited in scope and enforcement.

The effects of water pollution during the Industrial Revolution were lasting and widespread. By the middle of the 20th century, countries around the world began to feel the impact of water pollution. It led to the emergence of an environmental movement in the 1960s, which resulted in legislative victories such as the Clean Water Act in 1972.

No, the impact of the Industrial Revolution on waterways varied depending on the region and the level of industrialization. Highly industrialized areas, such as cities with many factories, were more affected by water pollution. American waterways, for example, were heavily polluted with oil and debris due to improper industrial practices.