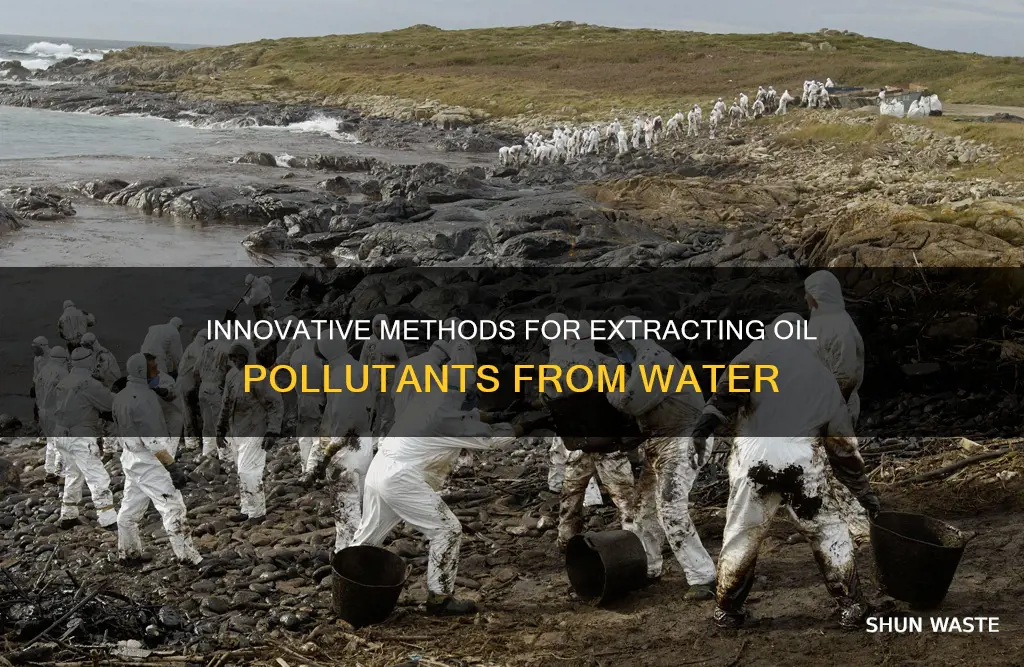

Oil spills are becoming increasingly common, and the cleanup process is challenging. Oil pollution is not only caused by human error but also occurs naturally, with oil seeping from the ocean floor and eroding sedimentary rocks. Oil spills have a devastating impact on wildlife, and the cleanup process must be handled carefully to avoid causing further damage. Responders use a variety of methods to remove oil from water and shorelines, including booms, skimmers, dispersants, and burning. Businesses should prioritise environmentally responsible practices and comply with local regulations to ensure the proper disposal of oily waste.

Characteristics and Values of Oil Removal from Water

| Characteristics | Values |

|---|---|

| Oil Spill Removal Techniques | Booms, skimmers, dispersants, burning, vacuuming, sorbents, shoreline cleaners, biodegradation agents, manual removal, mechanical removal |

| Eco-friendly Options | Biological treatment using bacteria, coated steel mesh, coated cotton fabric, solar-powered equipment |

| Water Treatment Processes | Coagulation, sedimentation, filtration, disinfection |

| Oil-Water Separation Methods | pH adjustment with oil skimming, coalescing oil-water separators, chemical treatments, demulsifiers |

| Oil Spill Modelling and Simulation Tools | CAMEO, MARPLOT, CRW, ROC, GNOME, CAFE, ADIOS |

| Oil Spill Prevention | Proper disposal of oil, paint, and hazardous chemicals, reducing possibility of diesel spills |

What You'll Learn

Using eco-friendly options like biological treatment with bacteria

Oil spills are a significant environmental concern, and while some oil pollution is natural, such as oil seeping from the ocean floor or eroding sedimentary rocks, most are caused by human activity. When oil spills happen, responders often use booms, skimmers, dispersants, or even burning to remove the oil from the water. However, an increasingly popular method for addressing oil spills is the use of eco-friendly options like biological treatment with bacteria.

Biological treatment using bacteria is an effective way to remove and prevent oil pollution in water. This process involves introducing "oil-eating" bacteria, such as Alcanivorax, which break down the oil into innocuous substances like carbon dioxide and fatty acids through a process called biodegradation. These bacteria can be deployed in the form of booms laced with slow-release fertilizer to promote their growth. The addition of nutrients like nitrogen and phosphorus further aids the process by making the oil more "palatable" for the bacteria, allowing them to ingest more oil.

One of the key advantages of using bacteria is their ability to break down oil into harmless substances. Unlike chemical dispersants, which can leave behind a heavy carbon residue, bacteria naturally degrade the oil, reducing the risk of secondary pollution. Additionally, bacteria can access and break down oil in both surface and underwater spills, making them a versatile solution.

While biological treatment with bacteria is a promising approach, it is important to note that the success of this method depends on certain conditions. For example, in the Gulf of Mexico oil spill, the sheer volume of oil exceeded the capacity of the bacteria to break it down, even with added nutrients. In such cases, a combination of methods may be necessary, including the use of skimmers to collect oil from the surface before deploying bacteria to address any remaining oil.

Overall, using eco-friendly options like biological treatment with bacteria is a safe and effective way to address oil pollution in water. By harnessing the power of microorganisms, we can minimize the environmental impact of oil spills and work towards a more sustainable future for our planet.

Air Pollution's Watery Path: A Complex Journey

You may want to see also

Employing booms, skimmers, and dispersants

When oil spills happen, responders may use booms, skimmers, and dispersants to remove oil from the water. Booms are floating physical barriers to oil, which help keep it contained and away from sensitive areas, like beaches, mangroves, and wetlands. They are commonly placed across narrow entrances to the ocean, such as stream outlets or small inlets, to prevent oil from passing through into marshland or other sensitive habitats. Hard booms are floating pieces of plastic that are cylindrical at the top and weighted at the bottom, giving them a "skirt" under the water.

Skimmers are used off boats to "skim" oil from the sea surface, often with the help of booms. Two boats may tow a collection boom, allowing oil to concentrate within the boom, where it is then picked up by a skimmer. Skimming is achieved with boats equipped with a floating skimmer designed to remove thin layers of oil from the surface.

Dispersants are chemicals that break up oil slicks on the water's surface. They release the tension between the oil and water and reduce the oil droplet size so that it can be distributed in the water column and biodegraded by naturally occurring microorganisms. This method is considered favorable as it prevents large quantities of oil from covering coastlines and sensitive habitats. However, there is a concern that adding these chemical dispersants to the ocean is poisoning fish, corals, and other marine species.

Industries' Environmental Impact: Air and Water Pollution

You may want to see also

Burning oil off the water's surface

In situ burning requires careful planning and coordination to ensure its effectiveness and safety. During the 2010 Deepwater Horizon/BP oil spill, in situ burning played a significant role in reducing the amount of oil on the water's surface. The operation involved multiple task forces, including ignition teams, supply vessels, safety teams, and fire boom teams. The complex logistics of coordinating the various teams were managed by the ISB Unit to ensure the process was carried out safely.

There are different techniques for conducting in situ burning. One method is to use a Heli-torch, a device attached to a helicopter that releases burning gelled fuel onto the oil. Another technique involves using specially designed pyrotechnic devices, such as a Pyroid or Dome igniter, which can be released by hand from a ship or dropped by helicopter onto the oil. These devices help facilitate the burning process and ensure that the oil is effectively ignited.

It is important to note that in situ burning can only be conducted under favourable weather conditions. Typically, if the sea is two to three feet or less, in-situ burning is feasible. If the seas are too high, the burning will need to be discontinued. Additionally, the potential impact on wildlife and the environment must be carefully considered. While laboratory tests suggest that burn residues may have limited aquatic toxicity, their greatest impact could be on the benthos (life on the ocean floor) through smothering.

Overall, burning oil off the water's surface is a viable method for removing oil spills, but it must be carefully managed to minimize any potential negative consequences and ensure the safety of the environment and personnel involved.

Ocean Pollution: Understanding the Human Impact

You may want to see also

Using belt oil skimmers to break surface tension

Oil spills are a significant environmental concern, and responders have developed various methods to address them, including the use of belt oil skimmers. These devices are designed to efficiently remove oil from the surface of water by taking advantage of the difference in surface tension between oil and water.

Belt oil skimmers utilise a rotating endless belt, typically made of corrosion-resistant steel or synthetic materials like polyurethane, that passes through a pulley system. This belt attracts and collects the floating oil by breaking the surface tension of the water. The oil is then wiped off the belt by a set of wiper blades. One of the critical aspects of using a belt oil skimmer is ensuring proper positioning. The skimmer should be located opposite the inflow, with the tail pulley submerged approximately two inches below the surface. This setup helps maintain the belt's position over the pulley for effective oil recovery.

When selecting a belt oil skimmer, it is important to consider the removal capacity rather than solely relying on belt length. The length of the belt should be chosen to ensure contact with the liquid at its lowest level. Additionally, the mounting of the skimmer should be convenient for routine servicing and maintenance. It is also worth noting that belt oil skimmers work better at ambient temperatures, as elevated temperatures can cause the belt material to lose structural integrity and tension.

While belt oil skimmers are widely used, they do have some limitations. Firstly, they are most effective when the coolant surface is stable. Turbulence can break the oil film, causing the oil to mix with the water instead of floating on the surface. Secondly, the type of belt material is crucial, as certain oils and coolants may interact differently with the belt, impacting the overall effectiveness. Finally, belt oil skimmers may require manual intervention to direct the oil towards the belt, as they follow a fixed path and only come into contact with a small portion of the oil-covered surface.

Despite some limitations, belt oil skimmers remain a popular choice for removing oil from water surfaces. They offer an economical and reliable solution, especially with advancements such as the Brill® tube-type oil skimmer, which addresses common challenges associated with traditional belt skimmers.

Dams: Water Pollution or Conservation?

You may want to see also

Using sorbents, specialised absorbent materials

Sorbents are a crucial tool in cleaning up oil spills. They are materials designed to absorb liquids and can be used to contain and remove oil from water or other surfaces. There are various types of sorbents, each with unique properties and applications.

One type of sorbent is the oil-absorbing pad or roll, which is commonly used in oil spill response. These pads and rolls are made of hydrophobic (water-repelling) fibres, allowing them to soak up oil while repelling water. They are typically laid on the water's surface to absorb the oil, preventing it from spreading further. Once they have absorbed the oil, they are collected and disposed of properly, along with the captured oil.

Another variety of sorbents includes booms, pads, and granules. Booms, also known as oil booms, are long, floating barriers used to contain and control the spread of spilled oil. They are usually made of materials such as PVC, polyurethane, or polypropylene, which enable them to float on the water's surface and absorb oil. By encircling the spilled oil, booms create a barrier that prevents oil from reaching sensitive areas like marshes, beaches, and wildlife habitats.

Loose sorbents, such as clay, sand, or vermiculite, can also be used for oil spill cleanup. These materials are spread over the water's surface to absorb oil, but they are less commonly employed due to the challenges in handling and collecting them once they become saturated with oil.

When choosing a sorbent for oil spill cleanup, it is essential to consider the specific situation and select the most suitable type to minimise any negative impact on the environment. Additionally, proper disposal of used sorbents is crucial to ensure environmental compliance and sustainability.

Sorbents play a vital role in addressing oil spills, providing a means to contain and remove oil from water and other affected areas. By selecting and using sorbents appropriately, responders can effectively manage oil pollution and mitigate its impact on the environment.

Human Activities: Creating Water Pollution

You may want to see also

Frequently asked questions

Some methods to remove oil from water include using booms, skimmers, dispersants, or burning the oil.

Booms are floating physical barriers to oil that help contain it and keep it away from sensitive areas like beaches and wetlands.

Skimmers are used off of boats to "skim" thin layers of oil from the sea surface, often with the help of booms.

Dispersants are chemical agents that can break up oil slicks from the surface.

Other methods include using industrial-sized vacuum trucks, sorbents (absorbent materials), shoreline cleaners and biodegradation agents, and manual or mechanical removal.