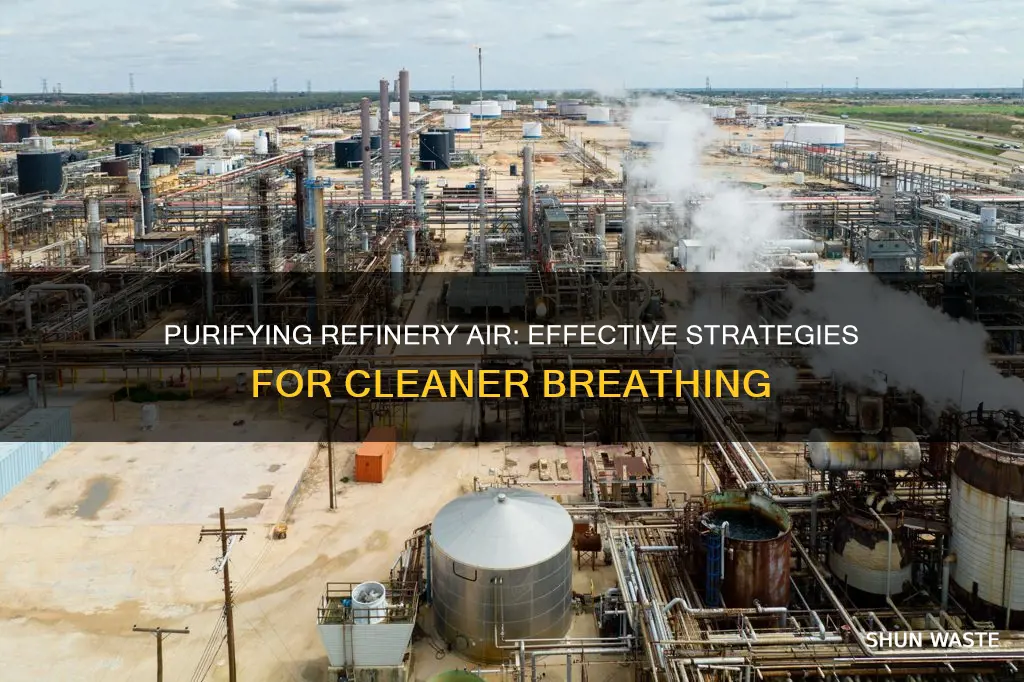

The oil industry is a significant contributor to air pollution, with the refining sector being the most polluting segment. Oil refineries employ chemical processes to transform crude oil into valuable products, but these processes release harmful pollutants such as carbon monoxide, sulphur dioxide, nitrogen oxides, and particulate matter. These emissions can have detrimental effects on both the environment and public health, making it crucial to implement effective pollution control measures. To protect ecosystems and human health, it is essential to prioritize monitoring, mitigation, and the adoption of sustainable practices in the oil refining industry. This includes improving boiler management, utilizing more efficient pumps, and implementing environmental protocols to reduce air pollution and move towards global decarbonization.

How to Purify Refinery Air Pollution

| Characteristics | Values |

|---|---|

| Environmental Protocols | Imposing environmental protocols is crucial for controlling air pollution in the petroleum refining industry to protect human health and ecosystems. |

| Monitoring Emissions | Continuous measurement of emissions from refineries is essential for detecting leaks, preventing exceedances of legal limits, and optimising processes to minimise environmental impact. |

| Gas Purification Systems | Wet scrubbers and baghouse filters are commonly used to reduce particulate matter and pollutants. |

| Energy Efficiency | Promoting energy efficiency in refineries, such as through the use of more efficient pumps, can help reduce air pollution. |

| Boiler Management | Better management of boilers can lead to significant savings in natural gas consumption. |

| Global Decarbonisation | Oil refiners' commitment to global decarbonisation efforts is vital to reduce air pollution and preserve health and ecosystems. |

What You'll Learn

Monitor emissions to minimise environmental impact

The commitment of oil refiners to monitor and control their emissions is essential to move towards global decarbonisation and to preserve health and ecosystems. Continuous and rigorous monitoring of emissions from refineries is crucial to minimise their environmental impact and protect public health.

Refineries employ a range of chemical processes to transform crude oil into valuable products with a wide range of uses. However, these refining processes are a significant contributor to air pollution, releasing harmful gases and particulate matter into the atmosphere. These emissions can dramatically worsen air quality and have severe ecological and health consequences.

To minimise the environmental impact, refineries must implement a combination of capture, treatment, and monitoring technologies. Continuous measurement of emissions is essential for detecting leaks, preventing exceedances of legal limits, and optimising industrial processes. It also ensures compliance with environmental regulations, reducing the risk of penalties. Without proper monitoring, uncontrolled emissions can cause irreversible ecological damage and increase the risk of respiratory and cardiovascular diseases in surrounding communities.

Some of the commonly used technologies for monitoring and controlling emissions include gas purification systems such as wet scrubbers and baghouse filters, which effectively reduce particulate matter and pollutants. Additionally, better management of boilers can lead to significant savings in natural gas consumption, contributing to reduced emissions.

Air Pollution's Reach: Understanding Its Spread

You may want to see also

Reduce carbon monoxide, nitrogen oxide, and sulphur dioxide emissions

Nitrogen oxides (NOx) are formed when nitrogen and oxygen react under high temperatures, especially in engines and industrial processes. The combustion of fossil fuels, such as in vehicles, ships, power plants, and industrial activities, is the primary source of NOx emissions. To reduce NOx emissions, modern emissions control strategies include limiting the amount of oxygen during combustion by optimising the air-fuel ratio. This reduces the conditions that favour NOx formation. Additionally, technologies like selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) can be employed to target NOx post-combustion, converting it into harmless nitrogen and water. Using alternative fuels, such as natural gas and electricity, and cleaner fuels, such as low-sulfur diesel, can also contribute to lowering NOx emissions.

Sulphur dioxide (SO2) emissions are prevalent in all stages of the oil and gas industry, including exploration, extraction, refining, transportation, and marketing. Refining is the most polluting stage, as the process aims to remove sulfur from crude oil to reduce SO2 formation during fuel combustion. To reduce SO2 emissions, refineries can employ emission control systems, test and repair heat exchanger leaks, and control equipment leaks. Continuous monitoring and measurement of emissions are crucial to identifying and reducing pollution sources. The US Petroleum Refinery Emission Reduction Strategy aims to reduce risks from the oil and gas industry's emissions by at least 20%.

Carbon monoxide (CO) emissions can be significantly reduced by implementing carbon capture technologies, such as Carbon Clean Up Solutions (CCUS). These technologies can capture up to 90% of the CO2 emitted from oil refineries, contributing to the world's net-zero goals. The specific emission reduction strategies depend on the configuration of the refinery, the type of fuel used, and the crudes processed. For instance, heavy sour crudes require more energy to process than light sweet crudes, resulting in higher carbon emissions.

Overall, reducing carbon monoxide, nitrogen oxide, and sulphur dioxide emissions from refineries requires a combination of process optimisation, technology implementation, alternative fuel sources, and stringent emission monitoring and control strategies. These measures not only improve air quality but also help mitigate the environmental and health risks associated with refinery air pollution.

Hydrogen's Impact: Air Pollution or Clean Energy?

You may want to see also

Implement gas purification systems

The oil industry is a significant contributor to air pollution, with the refining sector being the principal source of emissions. To mitigate this, implementing gas purification systems is crucial. Here are the key steps and considerations for implementing gas purification systems in the context of refinery air pollution:

Identify Pollutants

Firstly, it is essential to identify the specific pollutants emitted during the refining processes. Common pollutants released by refineries include sulphur dioxide (SO₂), nitrogen oxides (NOx), volatile organic compounds (VOCs), and particulate matter (PM). Understanding the types of pollutants produced will guide the selection of appropriate gas purification technologies.

Select Purification Technology

Various gas purification technologies are available, each with its advantages and limitations. Here are some commonly used methods:

- Biological Gas Purification: This method employs microorganisms to metabolize and degrade pollutants. It is effective for treating gas streams with low organic loads and offers advantages such as low operating temperatures and costs. However, it is not suitable for gases containing organic sulfur compounds.

- Wet Scrubbers: Wet scrubbers use a liquid to capture and remove contaminants from the gas stream. They are effective in reducing particulate matter and pollutants like acidic gases.

- Baghouse Filters: These filters capture solid particles, dust, and pollutants from the gas stream, helping to improve air quality.

- Cryogenic Gas Purification: This method utilizes differences in the boiling temperatures of constituent components to separate and purify gases.

- Incineration: Incineration is commonly used for disposing of hazardous wastes. It involves combustion and can be combined with flue gas purification techniques.

Design and Implement Purification Systems

Once the appropriate purification technology is selected, the next step is to design and implement the purification systems. This includes determining the required capacity, integrating the systems into the refinery processes, and ensuring uniform inlet materials to maintain stable combustion. Additionally, consider combining multiple methods to target specific pollutants effectively.

Monitor and Maintain

Regular monitoring and maintenance of the gas purification systems are crucial. Continuous measurement helps detect leaks, prevent exceedances of legal limits, and optimize the purification process. Proper monitoring also ensures compliance with environmental regulations and minimizes the environmental and health impacts of refinery emissions.

Explore Advanced Solutions

Explore advanced gas purification solutions offered by specialized companies. For example, Entegris provides a range of gas purifiers that remove various impurities, including halogenated gases, hydrides, reactive oxides, and hydrocarbons, with high reliability and performance.

Car Exhaust: Poisoning Our Air and Health

You may want to see also

Improve boiler management

Improving boiler management is a key aspect of reducing air pollution in oil refineries. Boilers are a significant source of air pollution, emitting hazardous air pollutants (HAPs), particle pollution, and volatile organic compounds (VOCs). These emissions contribute to health issues for employees, residents, and the wider community.

To improve boiler management and reduce air pollution, several strategies can be implemented:

Transition to Electric Boilers:

Refineries can replace fired boilers with electric boilers, which have lower carbon emissions and do not produce the same level of air pollutants as their fired counterparts. This switch can significantly contribute to decarbonization efforts.

Fuel Source Alternatives:

Natural gas-fired boilers are cleaner and more efficient than traditional coal-fired boilers. Additionally, waste fuel gas from petroleum refinery plants can be used as an alternative fuel source, reducing fuel consumption and carbon dioxide emissions.

Supply-Air Humidification:

Implementing supply-air humidification in boilers can improve overall boiler efficiency and reduce pollutant emissions. However, the amount of humidification must be carefully controlled to avoid excessive carbon monoxide (CO) generation.

Pollution Control Devices:

Utilize supplementary pollution control devices, such as economizers or superheaters, to minimize the release of pollutants. These devices can be integrated into the boiler system to capture and reduce emissions before they enter the atmosphere.

Desulfurization:

Implement desulfurization processes to recover sulfur and its compounds from gases before they are released. This method specifically targets sulfur, a leading source of air pollution responsible for acid rain, and effectively reduces its environmental impact.

Collaboration and Compliance:

Engage with boiler owners, operators, and local communities to develop and implement pollution reduction plans. Conducting energy audits and staying compliant with regulations can help identify cost-effective measures to reduce emissions.

Air Conditioning: Friend or Foe to Air Quality?

You may want to see also

Establish and impose environmental protocols

Establishing and imposing environmental protocols is paramount in the petroleum refining industry to control air pollution and safeguard human health, flora, and fauna. Here are several measures that can be implemented to achieve this:

Regulatory Compliance and Monitoring

- Refineries should adhere to stringent environmental regulations and standards set by governing bodies to minimize their environmental footprint.

- Continuous emission monitoring is crucial to detecting leaks, preventing exceedances of legal limits, and optimizing industrial processes. Proper monitoring also ensures compliance with regulations and helps avoid penalties.

- Monitoring technologies, such as gas purification systems (e.g., wet scrubbers and baghouse filters), can effectively capture and reduce particulate matter and pollutants emitted from refineries.

Sustainable Practices and Energy Efficiency

- Sustainable practices, such as improving boiler management, can lead to significant savings in natural gas consumption.

- Energy efficiency initiatives, including the utilization of more efficient pumps and compressors, can contribute to reducing air pollution and promoting sustainable development.

Global Collaboration and Benchmarking

- Countries with higher emission factors, such as Iran, can aim to align their emission standards with those set by the European Community or other global benchmarks.

- Global collaboration and knowledge sharing can help identify best practices and successful strategies for reducing air pollution from refineries.

Long-Term Planning and Investment

- Long-term investment strategies are essential to support the transition to sustainable practices. For example, the Islamic Republic of Iran needs to invest 95 billion USD in its oil refineries by 2045 to achieve sustainable development goals.

- Planning for the future includes considering alternative energy sources and processes that can reduce the environmental impact of the petroleum industry.

By implementing and enforcing these environmental protocols, the refining industry can play a pivotal role in global decarbonization efforts, protecting ecosystems, and preserving the health and well-being of communities worldwide.

Air Pollution: A Dangerous Trigger for Asthma Attacks

You may want to see also

Frequently asked questions

Refinery processes are a significant contributor to air pollution, emitting harmful gases and particles that can affect the health of surrounding communities and the ecosystem. Purifying and reducing these emissions are crucial to preserving the health of people and the planet.

Monitoring emissions is critical to managing refinery air pollution. This involves using technology to continuously measure and control the release of pollutants, such as sulphur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. Implementing environmental protocols and regulations is essential to ensure emissions are minimised and controlled.

Strategies to reduce refinery air pollution include improving the management of boilers, optimising industrial processes, and utilising more efficient pumps. Additionally, investing in sustainable practices, such as the development of more efficient technologies and processes, can contribute to reducing air pollution from refineries.