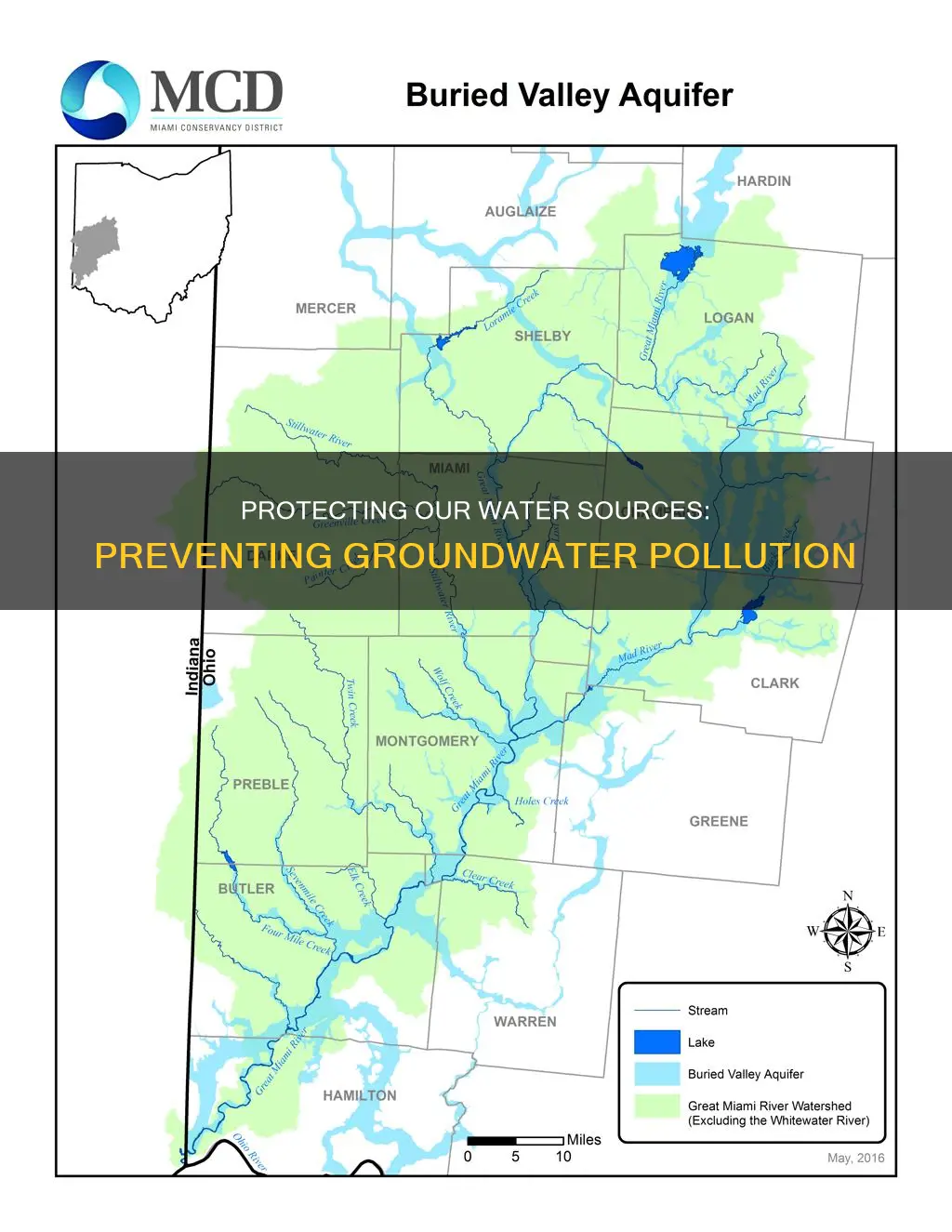

Groundwater is a fundamental part of the Earth's water resources, accounting for about 25% of the planet's overall freshwater supply. However, groundwater pollution is a serious global issue that threatens both human health and the environment. Groundwater pollution occurs when contaminants from various sources, such as industrial activities, agricultural practices, and improper waste management, seep into the groundwater and contaminate it. To prevent groundwater pollution, it is essential to take a comprehensive approach that involves governments, businesses, and communities. Effective measures include improving water governance, promoting sustainable agricultural practices, proper waste management, careful planning of well locations, regular inspections of high-risk areas, and implementing spill prevention and response plans. By addressing these issues, we can protect this valuable resource and ensure its availability for future generations.

| Characteristics | Values |

|---|---|

| Well location | A well located downhill from a livestock yard, a leaking tank, or a septic system has a higher risk of contamination than one on the uphill side. |

| Well depth | Shallow wells are more vulnerable to contamination than deep wells. |

| Soil type | Thick clay soils can prevent contamination by acting as a barrier to contaminants. |

| Distance from pollution sources | Increase the distance between wells and potential pollution sources such as silos, livestock yards, and manure stacks. |

| Drain covers and plugs | Use drain covers or plugs to prevent spills and leaks from entering floor drains in chemical storage and loading areas. |

| Spill and emergency response plans | Implement plans to handle spills and accidents, including the use of spill containment supplies. |

| Regular inspections | Inspect high-risk areas regularly to identify potential leaks or accidents before they occur. |

| Landfill design and maintenance | Properly design, maintain, and operate landfills, locating them away from sensitive groundwater areas. |

| Hazardous waste management | Ban hazardous wastes unless landfills are properly designed and monitored against dangerous levels of contaminants. |

| Underground storage tank regulations | Ensure underground storage tanks meet regulatory compliance policies for installation and maintenance. |

| Water governance | Strengthen groundwater governance by improving access to groundwater science and raising capacity for governance. |

| Monitoring and data transparency | Establish effective groundwater monitoring using modern methods and make data available to the public. |

| Agriculture practices | Shift to ecological agriculture and reduce beef consumption to decrease groundwater pollution from chemical agriculture. |

| Taxation and subsidies | Impose taxes or penalties on groundwater pollution caused by agriculture and eliminate subsidies contributing to unsustainability. |

What You'll Learn

- Well location: uphill from pollution sources, away from drainage and septic systems

- Seal wells to prevent surface water from entering groundwater

- Prevent spills by eliminating floor drains in chemical storage areas

- Install systems to collect runoff from silos

- Use anti-backflow devices to prevent chemical mixtures from contaminating groundwater

Well location: uphill from pollution sources, away from drainage and septic systems

The location of a well is a crucial safety factor. Locating a well in a safe place requires careful planning and consideration of factors such as the well's relation to surface drainage and groundwater flow.

A well located downhill from a livestock yard, a leaking tank, or a septic system is at a greater risk of contamination than a well situated uphill from these pollution sources. This is because pollutants can easily flow downhill and contaminate the water source. Shallow wells are particularly vulnerable as they draw from groundwater near the land surface, which may be directly impacted by nearby activities.

When planning a well location, it is essential to consider the surrounding land use and potential sources of pollution. For example, it is advisable to move chemical or gasoline storage areas away from the well and upgrade or better manage septic systems. Additionally, protecting high-risk areas with concrete curbs can help direct livestock yard runoff away from the well, reducing the risk of bacterial or nitrate contamination.

The type of soil in the well's vicinity is also a factor to consider. Thick clay soils, for instance, can prevent or delay contamination by acting as a natural barrier, whereas areas with thin soil over fractured bedrock or sand and gravel aquifers are more susceptible to pollutants reaching the water table.

Furthermore, understanding the local geologic conditions is vital as they influence how quickly pollutants can reach the groundwater. In some cases, contaminants can infiltrate the water table in a matter of hours or days. Thus, careful selection of the well location, taking into account both the surface and subsurface conditions, is essential to minimizing the risk of groundwater pollution.

Understanding Particle Size: What is PM?

You may want to see also

Seal wells to prevent surface water from entering groundwater

Wells are an important source of water for many societies, especially where surface water is scarce, such as in deserts. They are used for home use, irrigation, and industries.

To prevent surface water from entering groundwater via wells, it is important to seal the wells properly. Here are some measures that can be taken to seal wells effectively:

- Well caps: Place well caps on top of the well casing to prevent debris, insects, small animals, and surface water from entering the well. Well caps are usually made of aluminum or plastic and include a vent to control pressure during well pumping.

- Casing: Casing refers to the tubular materials that are permanent features of a well. It is important to use the appropriate casing materials, such as carbon steel, plastic, or stainless steel, depending on local geology. The casing should be watertight to prevent surface water from entering.

- Annular surface seal: The annular surface seal is crucial for preventing groundwater contamination. The minimum depth of the annular surface seal should be adhered to, with a length of at least 10 to 20 feet, depending on the enforcing agency's regulations.

- Bored wells: For bored wells, use concrete pipe or steel casing with watertight joints from 6 inches above the ground surface to the specified depth. If using corrugated steel pipe, ensure a thicker annular seal of at least 6 inches is installed.

- Pump placement: If the pump is offset from the well or a submersible pump is used, close the opening between the well casing and any pipes or cables with a watertight seal or "well cap".

- Groundwater flow: When placing sealing materials, use special care to restrict the flow of groundwater into the well boring, especially in areas with significant subsurface pressure.

By implementing these measures and following local regulations, wells can be effectively sealed to prevent surface water from entering and potentially contaminating groundwater sources.

Yellow Smoke: What Does It Mean?

You may want to see also

Prevent spills by eliminating floor drains in chemical storage areas

Preventing groundwater pollution is essential for protecting our water sources and the environment. One critical aspect of this is preventing chemical spills, which can have detrimental effects on both. One way to achieve this is by eliminating floor drains in chemical storage areas.

Floor drains are often located in chemical storage and loading areas, posing a significant risk of spills directly entering the drainage system and potentially reaching water bodies and the environment. By removing these drains, the likelihood of spills spreading and causing groundwater pollution is reduced.

If removing floor drains is not feasible, it is crucial to take preventive measures to protect them. This can be done by using drain covers or drain plugs, which act as barriers to prevent chemicals from entering the drains in the event of a spill. These covers and plugs are essential components of spill containment, ensuring that the impacted area can be controlled and contained.

Additionally, businesses should implement emergency response plans for spills. This includes regular inspections of high-risk areas to identify potential leaks or accidents before they occur and training staff to recognise and respond appropriately to spills. Having the necessary spill cleanup materials, such as absorbents and neutralising agents, readily available is also crucial.

By eliminating floor drains in chemical storage areas and implementing preventive measures, businesses can effectively reduce the risk of groundwater pollution from chemical spills, contributing to the protection of our precious water sources and the environment.

The Measure's Mystery: Unveiling C's Secret

You may want to see also

Install systems to collect runoff from silos

Silos are large structures used for the bulk storage of various materials, including grain, coal, cement, and woodchips. The runoff from silos, particularly bunker silos used to store silage, can be a significant source of groundwater pollution due to the presence of nutrients like nitrogen (N), phosphorus (P), ammonium, and phosphate, as well as high levels of organic pollutants.

To prevent groundwater pollution from silo runoff, it is essential to install effective collection systems. Here are some detailed instructions on how to install systems to collect runoff from silos:

Planning the Collection System

Before installing a runoff collection system for your silo, it is crucial to understand the specific characteristics of the silo and its contents. Consider the type of silo (tower, bunker, or bag), the materials stored, and the potential contaminants in the runoff. For example, if you are dealing with a bunker silo used for silage storage, you can anticipate high levels of nitrogen and phosphorus in the runoff.

Choose the Right Collection Method

The collection method you choose will depend on the specific characteristics of your silo and the nature of the runoff. One common method is to use a gutter and downspout system, similar to those used for rainwater collection. This involves attaching gutters and downspouts to the silo to collect and funnel the runoff into storage containers.

Install Storage Containers

You will need to install storage containers to hold the collected runoff. These containers should be sturdy and sealed to prevent leakage. The size and number of containers will depend on the expected volume of runoff. Consider using large rain barrels, which can be purchased from home centers or online. Ensure that the barrels are specifically designed for water storage and have not been used for chemicals or other harmful substances.

Implement a Filtration System

Install a filtration system to remove leaves, sticks, debris, and other objects that may be carried by the runoff. You can purchase specialized filters that attach directly to the downspouts, or you can install filters onto the barrels themselves if you are upcycling them. Regularly clean and maintain the filters to ensure their effectiveness.

Direct Runoff with Hoses

Use hoses to direct the runoff from the downspouts into the storage containers. Ensure that the hoses are securely attached and directed away from any buildings or structures. You can also attach a hose to the overflow at the top of the barrel to direct any excess runoff to the ground or into another barrel. Keep in mind that water pressure may be low, so expect a dribble rather than a steady stream.

By following these steps and adapting them to your specific needs, you can effectively install a system to collect runoff from silos, helping to prevent groundwater pollution and protect the environment.

The Measure's Intriguing Exploration: ABD 27 54

You may want to see also

Use anti-backflow devices to prevent chemical mixtures from contaminating groundwater

Groundwater pollution is a serious issue, and one way to prevent it is by using anti-backflow devices to stop chemical mixtures from contaminating groundwater. Backflow refers to the reversal of flow of liquids, gases, or suspended solids into the potable water supply, which can occur due to changes in water pressure. This can result in water that is unsafe for consumption, as contaminated water can enter the clean water line.

To address this, backflow prevention devices are designed to keep the potable water supply safe from contamination. These devices work by prohibiting wastewater from flowing back into the supply water line. There are various types of backflow preventers, including air gap devices, check valves, and specialized backflow preventer valves. Air gap devices are inexpensive and effective in preventing backflow by separating the hoses for clean and dirty water, ensuring they never intersect. Check valves, on the other hand, open and close based on pressure, allowing water to flow normally when pressure is normal, and shutting when output pressure is higher, preventing water from being pulled into the clean water line. Specialized backflow preventer valves are installed at strategic locations in the plumbing system to prevent contaminated fluids from entering the water supply pipes.

It is important to note that different backflow preventers employ unique mechanics depending on their application. For example, air gaps are commonly used in sinks and dishwashers to prevent debris and contaminated water from entering the drinking water supply. Check valves, being designed for continuous pressure systems, can be installed at the service entrance or individual water outlets. The specialized backflow preventer valves, meanwhile, are used when there is insufficient vertical clearance or physical space to install an air gap.

To ensure the proper functioning of backflow prevention devices, regular testing and inspection are crucial. Businesses are required by law to have these devices tested annually, and homes may also be subject to testing based on local legislation. This helps identify any wear and defects, maintaining the integrity of the potable water system. By utilizing anti-backflow devices and adhering to testing requirements, we can effectively prevent chemical mixtures from contaminating groundwater and safeguard our water supply.

Understanding the Meaning of P2

You may want to see also

Frequently asked questions

Groundwater is the world's most abundant freshwater resource, accounting for about 25% of the planet's overall freshwater supply. Groundwater pollution occurs when contaminants enter and taint this water supply, which can have severe effects on both human health and the environment.

Common sources of groundwater pollution include industrial pollution, agricultural activities, and land development. Other sources include road salts used to prevent slippery roads, leaking tanks, septic systems, and livestock yards.

The location of a well is a crucial safety factor. Wells located downhill from pollution sources such as livestock yards, leaking tanks, or septic systems are at a higher risk of contamination. Shallow wells are also more susceptible to pollution as they draw water from near the land surface, which can be directly affected by farmstead activities and surface runoff.

To prevent groundwater pollution, it is important to properly manage potential pollution sources and ensure that landfills and underground storage tanks are designed, maintained, and monitored in accordance with regulatory standards. Businesses should also implement spill containment measures and have emergency response plans in place to prevent and manage accidental releases of pollutants.

Governments should strengthen groundwater governance by improving access to groundwater science and implementing effective monitoring networks. They should also promote sustainable agricultural practices, impose taxes or penalties on groundwater pollution, and eliminate subsidies that contribute to groundwater unsustainability.