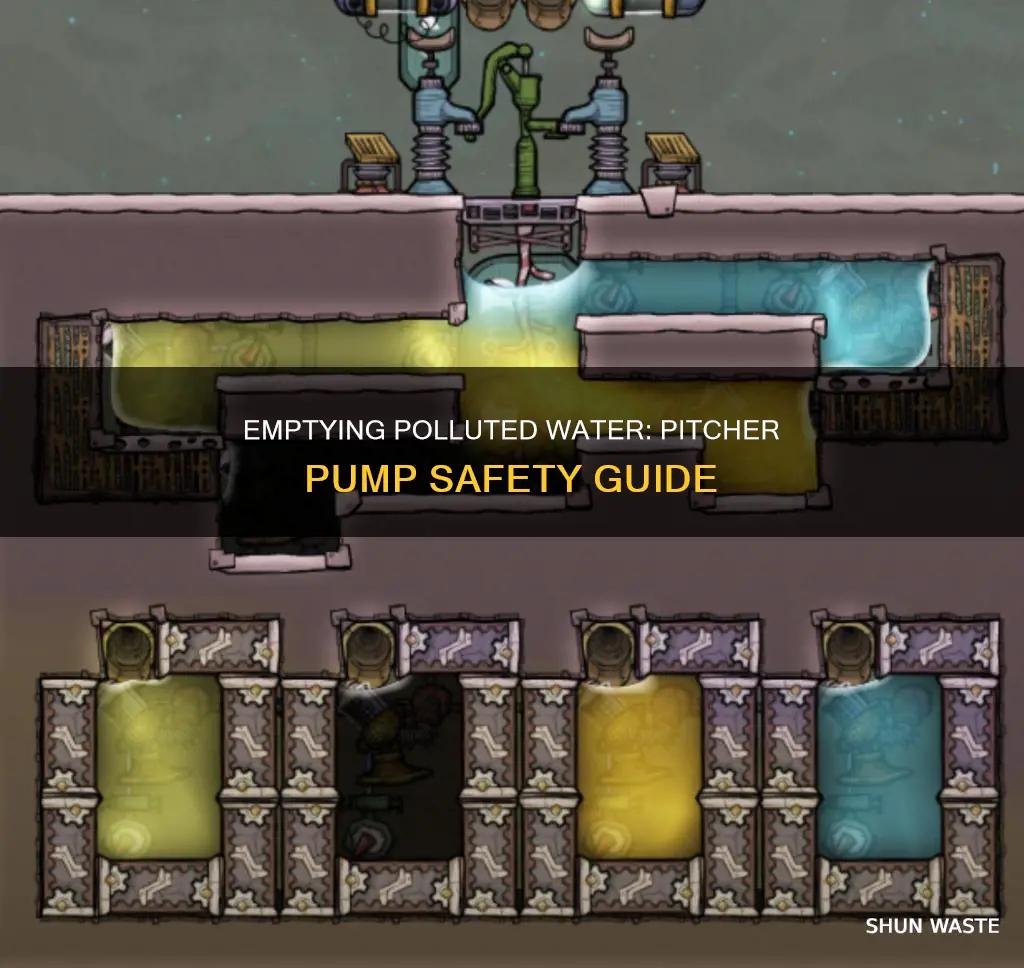

Pitcher pumps are used to pump liquid into bottles for transport. They are often used to remove unwanted liquid from a pool, such as polluted water. Polluted water is a breeding ground for bacteria and will make your Duplicants sick, so it is important to manage it effectively. One way to do this is by using a pitcher pump and auto-bottling bottle emptier to move the water to a storage area. Another method is to use a liquid pump to pump the polluted water into a water sieve or to put gulp fishes in the reservoir. If you don't have the resources to purify the water, you can simply isolate it by pumping it into a naturally occurring cavern or a carved-out reservoir.

How to empty polluted water into a pitcher pump

| Characteristics | Values |

|---|---|

| Pitcher pump | Used to pump liquid into bottles for transport |

| Bottle Emptier | Used in combination with the pitcher pump to empty bottles of liquid into specific locations |

| Auto-bottling | Option to be selected for the bottle emptier to work |

| Liquid Bottler | Required for supplying buildings that do not have piping intakes |

| Liquid Pump | Used to purify polluted water by pumping it into a Water Sieve |

| Gulp Fishes | Can be put into the reservoir to purify polluted water |

| Chlorine | Can be added to make purified water safe to drink |

| Ice Maker | Can be used to freeze the reservoir and store polluted water safely |

| Frozen Biome | Polluted water can be dumped here to be frozen and stored safely |

| Alternative to pitcher pump | Small reservoir with a drain that fills a pitcher pump |

| Polluted water usage | Can be used to grow plants like Pincha Pepper, Thimble Reed, and Arbor Tree |

| Can be converted into fertilizer using a Fertilizer Synthesizer |

What You'll Learn

Using a plumber to empty pipes for bottled liquids

If you're looking to empty polluted water into a pitcher pump, there are a few methods you can try. One option is to use a plumber to empty the pipes for bottled liquids. This method is mentioned in discussions about the game Oxygen Not Included.

To use a plumber to empty pipes for bottled liquids, here are the steps you can follow:

- Promote a duplicant to plumber: This will give them the ability to bottle liquids straight from the pipe. They can also use a valve to stop the liquid flow and prevent waste while bottling.

- Shut off the liquid source: If you start emptying a full pipe without shutting off the source, the pipe will keep filling up as you try to empty it.

- Cut the pipe: Before you can add a valve to stop the liquid flow, you will need to cut the pipe.

- Use a bridge to stop the liquid flow: If you don't want to use mods, you can build a bridge at the spot where you want to cut the pipe. Once the bridge is built, the pipe segment between the bridge input and output will be empty, and you can then safely deconstruct it without spilling any liquid.

- Deconstruct the pipe: After stopping the liquid flow, you can deconstruct the pipe to empty it.

It's important to note that this method is specific to the game Oxygen Not Included and may not apply to real-world plumbing situations. In real-world scenarios, it's generally recommended to call a professional plumber to handle pipe blockages and clogs, especially if you're dealing with older pipes or tree roots constricting your pipes. Over-the-counter chemical drain cleaners should be used with caution as they can damage pipes if used frequently.

Polluted Water: Deprived of Oxygen?

You may want to see also

Isolating polluted water with a pump and piping

Isolating polluted water is an essential step in managing the substance and preventing it from causing issues in your systems. Here is a detailed guide on how to isolate polluted water using a pump and piping:

Firstly, identify a suitable location to isolate the polluted water. This could be a naturally occurring cavern, a carved-out reservoir, or even a frozen biome if you want the environment to freeze the water.

Once you've chosen the location, acquire a pump designed to handle contaminated water, such as a Rotorflush pump with self-cleaning filters. These filters are essential to prevent blockages in the pump and connected equipment. Proper installation of the filter on the intake of the pump is crucial, ensuring it is securely attached and positioned correctly.

Next, connect the pump to a power source if necessary and place it in the polluted water. If the water is in a weird spot or there is not much of it, consider using a pitcher pump and auto-bottling bottle emptier to manually transport the water to your chosen location. This method is useful for generating polluted oxygen from polluted water bottles.

Now, you can begin pumping the polluted water out of its current location and into the chosen isolation area. Use piping to direct the flow of water from the pump to your desired location. Ensure that your pipes are connected correctly and consider using liquid bridges to control the direction of flow if needed.

Finally, monitor the self-cleaning process of the filter and perform regular maintenance. The filter will automatically backwash the screen to remove accumulated debris, but it is important to clean the filter mesh and inspect it for any signs of wear or damage.

By following these steps, you can effectively isolate polluted water with a pump and piping, preventing contamination in your systems and potentially turning this nuisance into a beneficial resource for your community.

Pollution's Pathways: Surface and Groundwater Contamination Sources

You may want to see also

Purifying polluted water with a liquid pump and water sieve

Firstly, select a suitable liquid pump that can handle pumping polluted water without getting blocked. Rotorflush pumps, for instance, are specifically designed for pumping dirty and contaminated water. These pumps have self-cleaning mechanisms that prevent debris from clogging the pump.

Next, you will need to set up the water sieve. The water sieve uses a filtration medium, such as sand or regolith, to purify the polluted water. It requires a supply of polluted dirt and receives polluted water through a liquid pipe connected to its input port. The water sieve will output purified water to the liquid pipe on its output slot, and it will drop polluted dirt on the floor when its internal storage is full. It is important to note that the water sieve does not change the temperature of the water, so be sure to keep polluted water sources separate from your main water supply to avoid contaminating your clean water with germs.

Now, you can begin the purification process. Pump the polluted water into the water sieve using your liquid pump. The water sieve will filter the water, and you can collect the purified water from the output pipe.

To maintain the system, be sure to perform regular maintenance checks on both the liquid pump and the water sieve. Keep the intake screens and filters clean and free of debris to prevent blockages. Additionally, ensure that your water sieve always has a sufficient supply of filtration media and polluted dirt to avoid interrupting the purification process.

By following these steps, you can effectively purify polluted water using a liquid pump and a water sieve. However, please note that this process may not remove all contaminants, especially germs, so additional treatment may be required depending on the intended use of the purified water.

Johnson City's Water Quality: Is It Safe?

You may want to see also

Storing polluted water in a pitcher pump for transport

Firstly, if the polluted water is in a small, manageable amount, it can be bottled and transported by hand to a storage area. This method ensures that the Duplicants will not be infected by germs, but care must be taken to ensure they do not accidentally use the polluted water for washing or other unintended purposes. This is a good short-term storage option.

For larger amounts of polluted water, a pitcher pump can be used in combination with a bottle emptier to move water from one pool to another. This method can achieve a maximum manual transport efficiency of 800 kg per run. The pitcher pump will pump the liquid into bottles, which the Duplicants can then carry to the desired location. To increase efficiency, auto-bottling can be turned on, and multiple bottle emptiers can be used.

Alternatively, a small reservoir with a pitcher pump can be built, which is then topped up from a pipe. This method ensures a constant supply of water and can be useful if the polluted water is in a weird spot or if you don't have the means to purify it immediately. The reservoir can be as small as 2 tiles wide and 4 tiles tall, and the pump will expand into the liquid below.

If you wish to simply get rid of the polluted water, it can be dumped into a cavern or a carved-out reservoir. An ice maker can be used to freeze the water and store it safely, or it can be dumped into a frozen biome to let the environment do the work. While this is the least efficient storage method, it is an option if you absolutely do not have a use for the polluted water and do not want to transport it.

Taiwan's Pollution Crisis: Air and Water Harms

You may want to see also

Using a bottle emptier to empty bottles of liquid

To empty bottles of liquid using a bottle emptier, you must first ensure that the bottle emptier is set up correctly. The bottle emptier is a building used to empty bottles of liquid into specific locations. By default, the only option in the Element Filter menu is water, but other liquids become available as the player discovers them.

To empty bottles of liquid, you must first ensure that the bottle emptier is set to "Auto-Bottle". This setting allows Duplicants to specifically bottle liquid at a Pitcher Pump and bring it to the Bottle Emptier. The Pitcher Pump sucks up the liquid, which can then be transported to the Bottle Emptier to fill an area. If you are planning on moving the liquid from one location to another by hand, you must set the Emptier to "Auto-Bottle".

It is important to note that the bottle emptier will only empty water that is in a bottle. If the water is in a reservoir, you will need to use a Pitcher Pump or mop the water on the floor. Additionally, the bottle emptier only shows how much water is available when the bottle is in the Emptier, not how much is stored elsewhere.

To control the amount of water taken from the Pitcher Pump, you can unclick "water" on the bottle emptier while it is emptying. This will result in less than 200kg of water being dispensed, as a bottle usually holds 200kg. Another trick to control the amount of water is to dump the liquid on a single tile where it can run off the sides. You can then mop up the remaining amount and set up the bottle emptier for the end destination, setting it to "sweep only" and sweeping the mopped bottle.

Boxed Water's Ocean Impact: Less Pollution, More Solutions

You may want to see also

Frequently asked questions

Place a pitcher pump over the liquid and have your Duplicants transport the bottles by hand to a storage area.

Pump the water via a liquid pump into a water sieve or put gulp fishes in the reservoir.

Pitcher pumps are useful for generating polluted oxygen from polluted water bottles. They are also useful for cooling and irrigation.

You can use a liquid pump with full pipes of water, a liquid bottler, or bottles to pipes.

Pincha Pepper, Thimble Reed, and Arbor Tree all need polluted water to grow.