Factories can take a number of steps to reduce water pollution. These include water treatment, reducing the waste produced, and changing the composition of products to reduce the waste produced from them. Factories can also adopt waste management systems, loss prevention, and waste segregation to help reduce water pollution.

| Characteristics | Values |

|---|---|

| Water treatment | Water treatment plants can eliminate dangerous elements from water |

| Waste reduction | Factories can reduce the amount of waste produced during the production process |

| Change product composition | Factories can change the composition of their products to reduce waste |

| Eliminate dangerous materials | Factories can reduce or eliminate dangerous materials used in the production process |

What You'll Learn

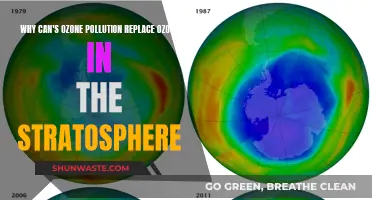

Water treatment

There are various methods of water treatment that can be used to reduce water pollution. One method is to treat wastewater before it is released back into the environment. This can be done through the use of advanced technology like pilot water treatment plants, which can help to reduce the impact of the growing water crisis.

Another method is to recycle water. This includes treating water before it can be used or released into nature. Water recycling can help to reduce the amount of wastewater produced, which in turn helps to reduce the number of contaminants in the water.

In addition to water treatment, factories can also implement waste management systems, waste minimization programs, loss prevention, and waste segregation to reduce water pollution. By reducing the amount of waste produced, factories can help to lessen the number of contaminants in the wastewater.

Earthquakes: Unseen Pollution Culprit and its Devastating Impact

You may want to see also

Reduce waste

Factories can reduce water pollution by reducing the amount of waste produced during industrial processes. This includes garbage, scrap metals, oils, chemicals, dirt, gravel, concrete, and trash. Factories can also adopt waste management systems, loss prevention, and waste segregation to reduce the amount of waste that ends up in the water.

Another way to reduce water pollution is to change the composition of products to reduce the waste produced from them. This can be done by reducing or eliminating dangerous materials used in the production process. Factories can also implement water recycling and preservation practices to reduce the impact of the growing water crisis.

Water treatment is an advanced and highly effective method to reduce water pollution. Water treatment plants can eliminate dangerous elements from the water, making it safer for human use and reducing the impact on the environment. Factories can also invest in pilot water treatment plants, which are an example of advanced technology that can help tackle water pollution.

Preventing Surface Water Pollution: Human Actions, Clean Water

You may want to see also

Change product composition

Factories can reduce water pollution by changing the composition of their products. This can be done by reducing or eliminating the use of dangerous materials in the production process. For example, factories can reduce the use of chemicals, oils, and metals that can contaminate water sources.

Another way to change product composition is to adopt a waste management system. This includes implementing waste minimization programs, loss prevention measures, and waste segregation practices. By reducing the amount of waste produced, factories can decrease the number of contaminants released into the water.

Additionally, factories can consider recycling water and treating wastewater before releasing it back into the environment. This helps to ensure that any pollutants are removed from the water, reducing the impact on natural water sources.

By changing the composition of their products and adopting sustainable practices, factories can play a crucial role in reducing water pollution and preserving clean water sources for future generations.

Air Pollution's Link to Seizures: A Health Concern?

You may want to see also

Waste management

Factories can reduce water pollution by implementing a waste management strategy. This includes waste minimisation programmes, loss prevention, and waste segregation. Factories should also reduce the amount of waste produced during the manufacturing process, as this will result in fewer contaminants in wastewater.

One way to reduce waste is to change the composition of products to reduce the waste produced from them. Factories should also reduce or eliminate dangerous materials used in the production process. This includes materials such as scrap metals, oils, chemicals, and concrete, which are harmful to the environment, humans, animals, and flora.

Water treatment plants are an advanced and highly effective method of reducing water pollution. Water treatment can eliminate dangerous elements from the water, and recycling water can also help to reduce water pollution.

Atmospheric Water Generators: Reducing Pollution, Harvesting Clean Water

You may want to see also

Water recycling

There are a number of ways that factories can recycle water. One method is to implement a waste management system that includes waste minimisation programs, loss prevention and waste segregation. This can help to reduce the amount of waste produced during industrial processes, resulting in less contaminated wastewater.

Another method is to use advanced technology, such as pilot water treatment plants. These plants are highly effective in treating wastewater and can help industries become more responsible in their water usage. Treating wastewater can eliminate dangerous elements and reduce the number of contaminants, making it safer for release back into the environment.

In addition to recycling water, factories can also preserve water to reduce pollution. This involves reducing water usage and implementing water-saving measures. By preserving water, factories can help to reduce the demand for clean water and bridge the gap between demand and supply.

Overall, water recycling is an important strategy for factories to reduce water pollution. By treating and reusing water, factories can minimise their impact on the environment and help to address the growing water crisis.

Water Pollution: Human Activities Causing Water Contamination

You may want to see also

Frequently asked questions

Factories can reduce water pollution by reducing the waste produced during industrial processes.

Factories can reduce waste by changing the composition of their products, eliminating dangerous materials from the production process, and adopting waste management systems.

Water treatment is an advanced and highly effective method that can help factories become more responsible by eliminating dangerous elements from the water.

Factories can also reduce water pollution by recycling water and using advanced technology like pilot water treatment plants.

Industrial waste makes up the majority of global water pollution, and it is harming the environment, humans, animals, and flora. Reducing water pollution will help bridge the gap between the demand and supply of clean water.