Manufacturing is a key driver of economic growth, but it also contributes significantly to pollution. The manufacturing process involves turning raw materials into finished goods, and the by-products of this process, including waste materials and substances produced, can be harmful to the environment. Manufacturing is a major source of air pollution, releasing toxic gases and chemicals into the atmosphere and waterways. The environmental impact of manufacturing is far-reaching, contributing to climate change, damaging ecosystems, and posing risks to human health. With manufacturing activities intensifying globally, addressing the pollution caused by this sector is crucial to mitigate its adverse effects on the planet and human well-being.

Water pollution

Water is highly vulnerable to pollution. Its unique properties as a "universal solvent" mean it can dissolve more substances than any other liquid, making it easily polluted. Industrial waste is the largest contributor to water pollution. This waste includes oils, chemicals, dirt, scrap metals, and more. Manufacturers may pollute water directly or indirectly. Indirect pollution occurs when waste and pollutants are left on the land and absorbed into the soil, eventually making their way into groundwater.

The manufacturing process transforms raw materials into useful goods, but the by-products can be harmful. Many manufacturing processes involve heating raw materials, such as oil refining, which releases pollutants into the air and water. For example, oil refining releases sulfur dioxide into the air and wastewater into streams, rivers, and lakes. Other processes, like paper and textile manufacturing, use chemicals such as chlorine and benzene, which can contaminate water sources. Leaking storage tanks can also allow chemicals to leach into groundwater.

In the US, the Environmental Protection Agency (EPA) is responsible for regulating chemicals in drinking water. However, studies show that over 200 million people are exposed to contaminated water linked to unregulated industrial practices. Communities, particularly low-income and marginalized ones, are forced to bear the burden of toxic pollution, facing higher water bills and health risks. The EPA has been criticized for failing to uphold its legal duty to protect waterways and for allowing outdated standards that enable heavy metals and toxic chemicals to pollute water sources.

To reduce water pollution, governments must establish and enforce clean water standards. Manufacturers can play a role by treating their wastewater before discharging it into waterways or recycling it for plant use. Different water treatment methods, such as reverse osmosis and ultrafiltration, can be employed to remove pollutants from the water.

Radon's Impact: Air Pollution and Health Risks

You may want to see also

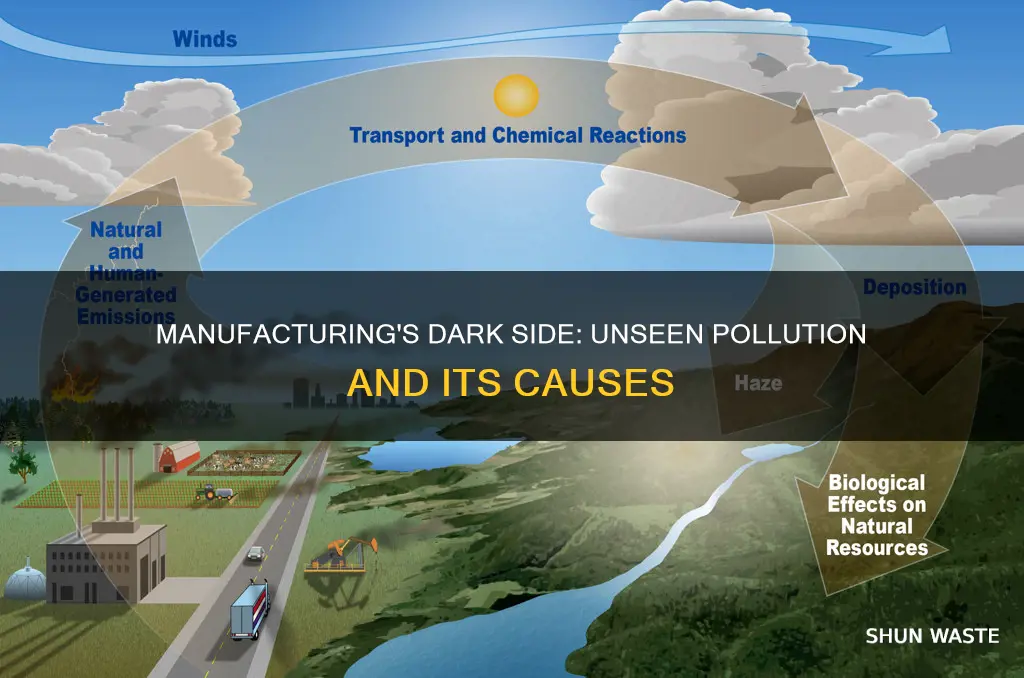

Air pollution

Industrial activities, such as oil and gas operations, petrochemical plants, steelmaking processes, and waste disposal, are major sources of air pollution. For example, the natural gas, plastic, chemical, electric generation, and waste disposal industries can generate hazardous waste that, if improperly managed, can lead to significant air pollution. Additionally, fracking, a common method for extracting natural gas, releases ethane, a raw ingredient in petrochemicals and plastics, contributing to further environmental damage.

The impact of air pollution from manufacturing and industrial processes is evident in regions like southwest Pennsylvania, particularly Pittsburgh and Allegheny County, where residents' health has been affected. To address this issue, organizations like the Clean Air Council work with local communities and governments to advocate for a transition away from natural gas and fossil fuels and towards cleaner energy sources. They also promote policies that address immediate health and environmental concerns, ensuring proper waste disposal and opposing waste incineration.

While the private sector has made efforts to reduce its carbon footprint and improve air quality, more needs to be done to control and reduce air pollution. This includes encouraging the use of renewable energy sources, such as wind, solar, and geothermal energy, and implementing regulations and standards for disclosing and reducing air pollutants. Initiatives like the Clean Air Act of 1970 and the Alliance for Clean Air are steps towards tackling air pollution and mitigating its detrimental effects on health, climate, and social equity.

It is important to note that air pollution is not limited to outdoor environments. Indoor air quality can also be affected by chemical sprays, asbestos, and natural pollutants like pollen and dust. Therefore, addressing air pollution requires a comprehensive approach that considers both outdoor and indoor sources of pollution and involves collaboration between governments, industries, and individuals to implement sustainable practices and reduce emissions.

Petroleum Pollution: Understanding the Environmental Impact

You may want to see also

Soil pollution

Manufacturing is one of the leading contributors to soil pollution. Industrial areas typically have much higher levels of trace elements and organic contaminants. This is due to intentional and unintentional releases from industrial processes directly into the environment, including the soil, water, and atmosphere.

For example, in electronics manufacturing, the improper dumping of unsafe materials like lead and mercury during production can lead to soil contamination. Similarly, chemical manufacturing can discharge untreated wastewater polluted with heavy metals and volatile organic compounds, destroying soil conditions. These pollutants can live on in the soil for decades, impacting soil quality and posing long-term threats to the environment and human health.

Another significant source of soil pollution is the inadequate disposal of manufacturing waste and wastewater. Spills, air emissions, and improper waste management can lead to widespread environmental contamination, not only in the immediate vicinity of manufacturing industries but also in remote areas.

To reduce the impact of manufacturing on soil pollution, proactive processes must be implemented. This includes adopting comprehensive waste management strategies, proper disposal and recycling of industrial waste, and employing containment systems to prevent accidental spills. Sustainable practices, such as reducing resource consumption, using eco-friendly raw materials, and limiting hazardous chemicals, are also crucial.

By embracing these strategies and investing in advanced pollution control equipment, businesses can significantly decrease soil pollution and protect the planet's future.

Asteroids, Water Pollution: What's the Connection?

You may want to see also

Climate change

Manufacturing is a major contributor to climate change, as the production of goods emits carbon dioxide and other greenhouse gases that cause global warming. This is primarily achieved through the burning of fossil fuels and certain industrial processes. In the US, the Environmental Protection Agency reports that manufacturing accounts for almost a quarter (23%) of direct carbon emissions. Similarly, in Europe, the industry emits 880 million tonnes of carbon dioxide annually, making it one of the largest emitters of greenhouse gases on the continent.

The manufacturing sector is projected to continue growing, alongside the global population and the development of nations. This will inevitably lead to an increase in emissions, with the CBO estimating that direct emissions from manufacturing will exceed those from the electric power sector by 2030.

A key challenge in reducing emissions from manufacturing lies in the production of steel and cement, which are essential for construction. Currently, there is no way to make these materials without releasing climate-warming emissions, and they account for about a third of global greenhouse gas emissions. However, there is optimism that the development of new technologies can reduce the environmental impact of manufacturing. For instance, it will soon be possible to create 100% fossil-free steel using fossil-free electricity and green hydrogen, significantly reducing the climate impact of steel production.

To address the climate crisis, the manufacturing industry must reduce its reliance on fossil fuels, increase recycling, and adopt more environmentally conscious design practices. The concept of a circular economy, which focuses on optimization and the "reuse, reduce, recycle" approach, can help make manufacturing more sustainable. Additionally, initiatives such as Mission Innovation, launched during the 2015 United Nations climate talks, aim to link governments with the private sector to pursue and share clean technology.

How Noise Pollution Impacts Whales and Causes Beaching

You may want to see also

Health issues

Manufacturing processes contribute to air pollution and water pollution, which have detrimental impacts on human health. The burning of toxic materials and gases, such as carbon dioxide, methane, and sulfur dioxide, released into the atmosphere during manufacturing, has led to rising temperatures and climate change. This, in turn, increases the risk of natural disasters and the spread of diseases such as cholera, malaria, and Lyme disease.

Air pollution from manufacturing can cause both short- and long-term health issues. Short-term symptoms include painful coughs, difficulty breathing, headaches, and fatigue. Long-term exposure to air pollution can result in lung damage, suppressed lung growth in children, accelerated decline of lung function in adults, and an increased risk of lung cancer. It has also been linked to the onset of Type 2 Diabetes and cardiovascular diseases, including heart disease, stroke, and atherosclerosis. Additionally, air pollution can impact brain development in young children and fetal brain growth in pregnant women.

Water pollution from manufacturing processes can contaminate drinking water sources, leading to health issues for those who consume it. The illegal dumping of contaminated water, chemicals, and toxic wastes into waterways can damage marine life and the environment. Leaking storage tanks containing chemicals can also leach into groundwater, further exacerbating water pollution. Soil pollution, caused by industrial waste disposal in landfills, can destroy soil fertility, decrease crop productivity, and contaminate food sources, posing risks to human health.

The health impacts of manufacturing pollution are particularly prominent in lower- and middle-income countries (LMICs) due to the lack of resources and regulations to implement cleaner production methods. The rise in pollution-related chronic diseases, such as asthma, heart disease, and strokes, has been linked to increasing industrialization and the consequent contamination of air, water, soil, crops, and livestock.

To mitigate the health issues caused by manufacturing pollution, regulations and interventions have been put in place, such as the Clean Air and Clean Water Acts, which have helped reduce concentrations of pollutants in the environment. Additionally, initiatives such as the Sustainable Manufacturing and Environmental Pollution (SMEP) program aim to develop solutions to reduce industrial pollution and its associated impacts on human health.

Combustion Devices: Air Polluters in Disguise

You may want to see also

Frequently asked questions

The manufacturing process often involves heating raw materials to transform them into more useful forms. For example, oil refining involves heating petroleum to high temperatures, which releases sulfur dioxide into the air. Burning coal or diesel fuels to provide steam power for the manufacturing plant also releases pollutants into the air.

Manufacturing methods can use large quantities of water, and the resulting wastewater can be released into streams, rivers, and lakes, adding pollutants to the water. Water pollution can also occur when tanks storing chemicals leak and leach into the groundwater. Paper and textile manufacturing, which use chemicals such as chlorine and benzene, contribute to water pollution.

Air pollution from manufacturing can cause respiratory issues such as asthma and allergies, as well as more serious illnesses like lung cancer and cardiac diseases. Water pollution can contaminate our food sources, leading to an increased risk of illnesses and diseases.

Greenhouse gas emissions from manufacturing, such as carbon dioxide, contribute to global warming and climate change. These gases absorb radiation from the sun, impacting the planet's temperature and leading to rising sea levels and an increased frequency of natural disasters.

Governments and industry leaders are implementing initiatives to reduce manufacturing pollution. This includes adopting renewable energy sources, transitioning to cleaner fuels and industrial processes, and offering incentives for companies to use environmentally friendly technologies. Individuals can also play a role by reducing their carbon footprint and supporting eco-friendly products.

![Emission reduction Q & A-3R practice field manual of the factory (2003) ISBN: 4879732516 [Japanese Import]](https://m.media-amazon.com/images/I/51A4WbNKK4L._AC_UL320_.jpg)