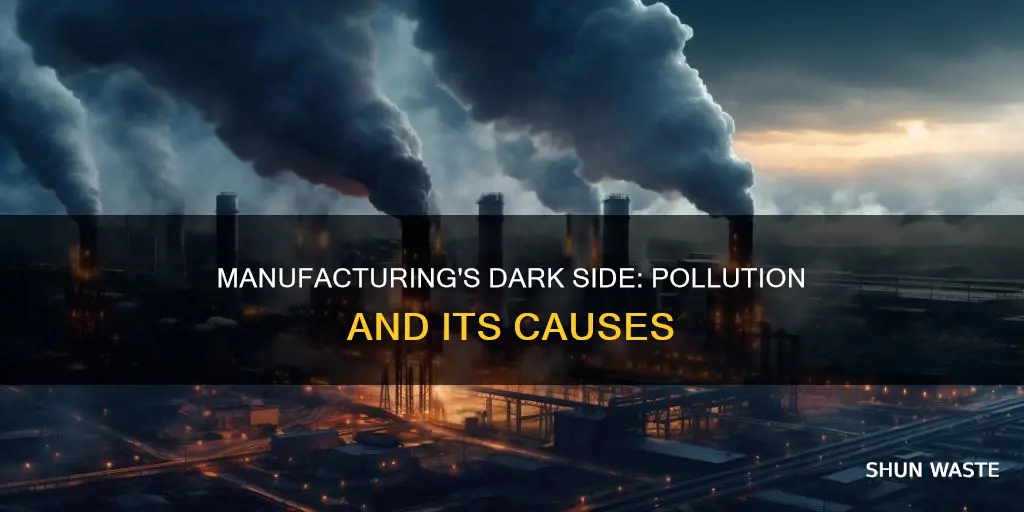

Manufacturing is an important part of the global economy, providing jobs and essential goods. However, it is also a significant contributor to pollution, which has detrimental impacts on the environment and human health. The manufacturing process often involves the use of toxic materials and the release of harmful by-products, such as waste materials and substances, into the air, water, and soil. This has led to air pollution, water contamination, and soil toxicity, causing damage to ecosystems and increasing the risk of diseases such as lung and heart conditions. While regulations and initiatives have helped reduce pollution in some regions, manufacturing continues to be a major polluter, particularly in less regulated areas.

| Characteristics | Values |

|---|---|

| Air pollution | Release of harmful gases, such as carbon dioxide, methane, and sulfur dioxide |

| Water pollution | Illegal dumping of contaminated water, gases, chemicals, heavy metals or radioactive materials into major waterways; wastewater from manufacturing processes |

| Soil pollution | Toxic waste disposal, chemical leaks, and industrial waste |

| Climate change | Greenhouse gas emissions, leading to rising sea levels and global warming |

| Health impacts | Increased risk of diseases, including cholera, malaria, Lyme disease, chest infections, lung diseases, heart diseases, and Type 2 Diabetes |

| Environmental damage | Endangerment of animal species, destruction of natural habitats, and negative impact on marine life |

| Energy consumption | High energy usage, with potential for cogeneration systems to utilise waste heat energy |

| Waste generation | Product waste and excessive waste heat energy |

| Export impact | Intensely high water consumption, land use, and soil toxicity associated with exports |

Air pollution

The impact of industrial air pollution extends beyond the atmosphere, as these toxic chemicals also contaminate waterways and soil. This occurs when factories illegally dump their waste into oceans or rivers, causing damage to marine life and the broader environment. Soil fertility and crop productivity decrease as a result of polluted earth, and food contamination can pose risks to human health.

The health consequences of air pollution are significant. According to the World Health Organization (WHO), 5% of lung cancer cases are attributed to prolonged exposure to pollution. Additionally, a small percentage of cardiac and lung infections, as well as heart diseases, are linked to pollution. The release of toxic gases by factories exacerbates these health issues, increasing the rates of asthma, allergies, and other respiratory problems.

To address air pollution, governments and organizations are taking action. The Clean Air Council, for example, works with communities and local governments to prevent hazardous industrial waste, oppose waste incineration, and advocate for comprehensive waste stream testing to identify pollutants. The transition to cleaner fuels and renewable energy sources, such as wind, solar, or geothermal energy, is also encouraged to reduce harmful emissions.

Smart technology has also emerged as a powerful tool in the fight against air pollution, aiding in monitoring and managing air quality. While these efforts are ongoing, it is essential for individuals to take steps to reduce their carbon footprint and limit their exposure to indoor and outdoor air pollutants.

Air Conditioners: Boynton Beach's Pollution Problem?

You may want to see also

Water pollution

Manufacturing processes can generate waste materials and by-products that are harmful to the environment, contributing to water pollution. This includes industrial waste such as garbage, oils, chemicals, dirt, concrete, and scrap metals, which can contaminate water sources directly or indirectly. Indirect contamination occurs when waste and pollutants left on land are absorbed into the soil and eventually reach groundwater, resulting in long-lasting effects on water systems.

Water is particularly vulnerable to pollution due to its solubility, easily mixing with toxic substances. The manufacturing process often involves heating raw materials, such as in oil refining, where high temperatures are used to separate petroleum into various grades of gasoline and other petroleum products. This releases sulfur dioxide and other pollutants into the air, which can eventually find their way into water sources.

The release of wastewater from manufacturing processes into streams, rivers, and lakes is a significant source of water pollution. This wastewater contains pollutants, including chemicals used in the manufacturing process, such as chlorine and benzene, commonly used in paper and textile manufacturing. Additionally, leaks from tanks storing chemicals can directly contaminate groundwater, posing a threat to drinking water sources.

In the United States, industrial waste is a major contributor to water pollution, with manufacturing companies being among the worst offenders. Despite the Environmental Protection Agency's (EPA) efforts to regulate chemical levels in drinking water, studies indicate that over 200 million people are exposed to contaminated water linked to unregulated industrial practices. This contaminated water not only affects human health but also has negative consequences for the environment, including aquatic life, plants, bacteria, and fungi.

To address water pollution from manufacturing, governments must establish and enforce clean water standards. This includes implementing external regulations and monitoring to ensure compliance. Manufacturers can play a crucial role in reducing water pollution by treating their wastewater before discharging it into water bodies or recycling it back into the plant for reuse. Various treatment methods, such as reverse osmosis, ultrafiltration, and nano-filtration, can be employed to remove pollutants from wastewater.

Chemical Pollution's Link to Diabetes: A Health Mystery

You may want to see also

Climate change

The manufacturing sector is responsible for a substantial portion of global greenhouse gas emissions. Energy consumption in factories and industrial facilities often relies on fossil fuels, contributing to CO2 emissions. Additionally, certain industrial processes release other potent greenhouse gases, such as methane (CH4) and nitrous oxide (NOX). Methane emissions commonly occur in the production and transport of coal, oil, and natural gas, as well as in the decay of waste in landfills. Nitrous oxide emissions can result from various manufacturing activities, including the production of adipic acid used in nylon and the emission of NOX during fossil fuel combustion.

The impact of manufacturing on climate change extends beyond greenhouse gas emissions. Industrial activities can also influence climate patterns through the release of pollutants and particulate matter into the atmosphere. For example, the emission of sulfur dioxide (SO2) and nitrogen oxides (NOx) from burning fossil fuels can contribute to the formation of acid rain and the production of fine particulate air pollution. These pollutants have direct health implications and can also affect climate patterns by influencing cloud formation and the Earth's radiation balance. Additionally, particulate matter, such as black carbon, released during the combustion of fossil fuels and biomass, can absorb sunlight and contribute to the warming of the atmosphere.

To address climate change effectively, it is imperative to reduce greenhouse gas emissions and transition to more sustainable manufacturing practices. This involves adopting cleaner energy sources, improving energy efficiency, and implementing carbon capture and storage technologies. Many companies are already taking steps to reduce their environmental impact, recognizing the importance of sustainability and corporate social responsibility. Governments also play a crucial role in implementing policies and regulations that encourage the adoption of cleaner technologies and promote sustainable practices. International cooperation is also vital to tackling this global challenge, as climate change transcends national boundaries and requires a unified response.

Hydroelectric Power: Clean Energy or Air Polluter?

You may want to see also

Health impact

Manufacturing and industrial pollution have a detrimental impact on human health. Research on the top 20 industrialised countries in the world found that industrial pollution significantly increases the death rate. The crude death rate was used to represent health status, with CO2 emissions from manufacturing industries, nitrous oxide emissions, and construction taken as indicators of industrial pollution.

The health impact of manufacturing pollution is wide-ranging. Air pollution from factories and industrial plants increases the risk of developing chronic respiratory disease, lung cancer, heart disease, and other illnesses. For instance, the World Health Organization (WHO) estimates that 5% of lung cancer diagnoses are due to extended exposure to pollution. Air pollution also suppresses the lung's normal growth rate and speeds up the decline of lung function. Furthermore, it has been linked to the onset of Type 2 Diabetes and the development of cardiovascular diseases such as stroke and atherosclerosis.

Water pollution is another significant concern. The illegal dumping of contaminated water, gases, chemicals, heavy metals, or radioactive materials into major waterways causes damage to marine life and the environment as a whole. Even the earth's soil can become polluted due to industrial waste being thrown into landfills, leading to potential contamination of the food we consume. Water pollution also affects humans directly, as seen in the case of the Wisconsin River, where fish could not survive in the mid-1970s due to pollution, but now support fish life thanks to the Clean Water Act.

The impact of manufacturing pollution is not limited to physical health but extends to mental health as well. Studies have shown that air pollution can impact brain growth in young children and pregnant women. Additionally, climate change exacerbates the effects of pollutant exposure, increasing the sensitivity of humans to the adverse consequences of industrial pollution.

While regulations and interventions have helped reduce pollution and its associated health risks in some regions, the impact of manufacturing pollution remains a significant concern, especially in lower- and middle-income countries (LMICs). The globalization of trade, low labour costs, and the spread of Western lifestyles have led to an increase in polluting industries in these countries, where environmental and public health protections are lacking. As a result, the health of vulnerable populations is disproportionately affected by the consequences of manufacturing pollution.

North Dakota Pipe: Drinking Water Pollution Risk?

You may want to see also

Environmental impact

Manufacturing processes involve turning raw materials into useful goods. However, some manufacturing methods use large quantities of water, which, when contaminated with waste or chemicals, can be released into streams, rivers, and lakes, adding pollutants to the water. This can also occur when tanks storing chemicals leak and leach into the groundwater. Paper and textile manufacturing, which use chemicals such as chlorine and benzene, contribute to water pollution.

The manufacturing process also produces waste materials and substances that are harmful to the environment and contribute to air and water pollution. For example, oil refining releases sulfur dioxide into the air, and burning coal or diesel fuel to provide steam power to run manufacturing plants releases pollutants into the air. Factories are a major contributing factor to water pollution and are responsible for two-thirds of greenhouse emissions. They release untreated sewage, industrial waste, toxic chemicals, and waste heat energy.

The environmental impact of manufacturing extends beyond air and water pollution. It also contributes to climate change and global warming, with toxic materials and gases released into the atmosphere, such as carbon dioxide and methane, which absorb radiation from the sun and impact the planet's temperature. This leads to rising sea levels, an increased frequency of natural disasters, and a risk of species extinction.

Additionally, manufacturing activities can directly destroy natural areas by clearing forests for wood and engaging in mining activities, which force animals to leave their natural habitats. Soil pollution, caused by the dumping of industrial waste into landfills, can also occur. This can destroy soil fertility, decrease crop productivity, and contaminate food sources, posing risks to human health.

While regulations, such as the Clean Air and Clean Water Acts, have helped reduce pollution in some regions, the environmental and health costs of industrial pollution remain high. Positive incentives, technology transfers, and the adoption of clean production technologies can help mitigate manufacturing pollution.

Hard Foam Pillows: Pollution and Health Risks?

You may want to see also

Frequently asked questions

Yes, manufacturing is a major contributor to pollution. Factories have been responsible for two-thirds of greenhouse emissions, and the manufacturing process creates harmful waste materials and substances that pollute the air, water, and soil.

Many manufacturing processes involve heating raw materials to transform them into more useful forms. For example, oil refining releases sulfur dioxide into the air, and burning coal or diesel fuel to power plants releases pollutants.

Some manufacturing methods use large quantities of water, and the resulting wastewater is released into streams, rivers, and lakes, adding pollutants to the water. Tanks storing chemicals can also leak and leach into the groundwater.

Air pollution from manufacturing has been linked to lung damage, an increased risk of Type 2 Diabetes, cardiovascular issues, and negative impacts on brain growth in young children and pregnant women. Industrial pollution has also been found to significantly increase the death rate.

![Emission reduction Q & A-3R practice field manual of the factory (2003) ISBN: 4879732516 [Japanese Import]](https://m.media-amazon.com/images/I/51A4WbNKK4L._AC_UL320_.jpg)