The global transition to electric vehicles has led to a skyrocketing demand for lithium, a critical component in battery production. However, the harsh reality behind this promise of a greener future is that lithium mining and extraction can cause significant environmental damage, including air pollution. The process of extracting lithium from the earth can contaminate the air, leading to adverse effects on the environment and human health. With the world's growing need for energy storage solutions, exploring more sustainable and ethical alternatives to traditional lithium mining is crucial to avoid sacrificing the planet's health for technological progress.

| Characteristics | Values |

|---|---|

| Air contamination | Lithium extraction can cause air contamination. |

| Carbon emissions | Lithium mining has a substantial carbon footprint due to energy and chemical use. |

| Water scarcity | Lithium mining can lead to water scarcity and impact local communities. |

| Soil degradation | Lithium mining can harm the soil and cause soil degradation. |

| Waste | Lithium mining generates large quantities of mineral waste. |

| Energy consumption | Lithium mining is energy-intensive, requiring substantial electricity for crushing, grinding, and chemical separation. |

| Pollution | Lithium batteries may contribute to environmental pollution due to potentially toxic materials. |

| Health impacts | Lithium batteries may have adverse human health impacts due to toxic materials. |

What You'll Learn

Lithium mining's carbon footprint

Lithium mining, like most mining activities, has a significant environmental footprint. The extraction process can harm the soil and cause air contamination, and in places like South America's lithium fields, it can lead to water scarcity and affect local communities.

The lithium extraction process uses a lot of water—approximately 500,000 gallons per metric ton of lithium. To extract lithium, miners drill a hole in salt flats and pump salty, mineral-rich brine to the surface. After several months, the water evaporates, leaving a mixture of manganese, potassium, borax, and lithium salts, which is then filtered and placed into another evaporation pool. This process requires a lot of freshwater to flush out solid lithium, posing a threat to freshwater supplies. The use of chemicals in the extraction process, such as hydrochloric acid and sodium carbonate, also contributes to lithium mining's environmental footprint.

The environmental consequences of lithium mining vary significantly. Traditional methods result in significant CO2 emissions due to the energy-intensive nature of the evaporation process. Newer methods, while more efficient, still have a substantial carbon footprint due to energy and chemical use. Lithium mining's carbon footprint is estimated to be around 1.3+ million tonnes of carbon annually, with every tonne of mined lithium equating to 15 tonnes of CO2 into the air. However, it is important to note that lithium mining has a lower carbon footprint than fossil fuel production.

The main pollution issue arises from poorly lined evaporation ponds, which can allow brine to infiltrate and contaminate near-surface freshwater aquifers. Lithium mining can also cause soil degradation, water scarcity, and air contamination, leading to biodiversity loss and damage to ecosystem functions. The production of lithium batteries can emit more carbon dioxide than manufacturing conventional cars. For instance, producing a 1,100-pound battery can emit over 70% more CO2 than making a traditional car in Germany.

Does Slow Driving Cause More Pollution?

You may want to see also

Water scarcity and pollution

The brine extraction method, commonly used in lithium mining, involves pumping lithium-rich brine from underground reservoirs to evaporation ponds on the surface. This process is known for its high water consumption and ecological disruption caused by the evaporation ponds and drilling operations. The use of chemicals in the extraction process and the land required for evaporation ponds further contribute to its environmental impact.

The risk of polluting local water sources is a significant concern. Toxic metals and chemicals used in the extraction process can contaminate water sources, threatening both human health and animal biodiversity. This pollution can lead to health issues, including respiratory problems, as hazardous metals enter the respiratory system.

To address these water-related challenges, alternative extraction methods, such as Direct Lithium Extraction (DLE), are being explored. DLE technologies aim to reduce water consumption and pollution by avoiding brine evaporation. However, the energy, water, and chemical requirements of these newer methods still need to be carefully considered during environmental impact assessments.

Overall, the water scarcity and pollution associated with lithium mining highlight the need for sustainable and responsible sourcing practices in the transition to renewable technologies. Recycling lithium and increasing the lifetime of lithium-ion batteries are crucial steps to reduce the environmental impact of lithium mining on water resources.

Air Contamination: Understanding the Root Causes and Sources

You may want to see also

Air contamination

The extraction of lithium has a significant environmental footprint, and the process can cause air contamination. Lithium is often found in salt flats, and the extraction process involves drilling a hole and pumping mineral-rich brine to the surface. After several months, the water evaporates, leaving a mixture of minerals and lithium salts. This process requires a lot of water—approximately 500,000 gallons per metric ton of lithium.

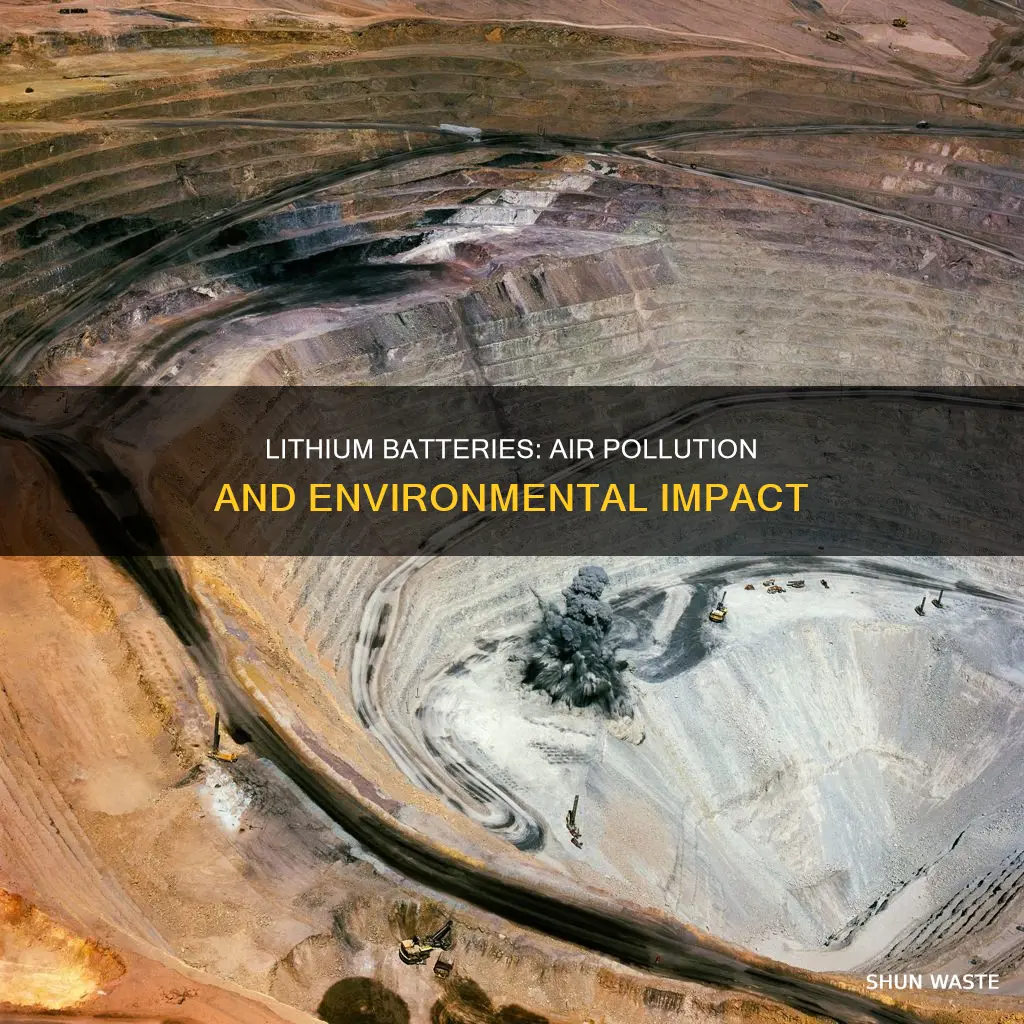

The visual impact of lithium mining is dramatic, with open-pit operations and vast evaporation ponds scarring the natural landscape. This aesthetic degradation is a permanent disruption to the environment and can have far-reaching consequences for tourism, recreation, and cultural values.

The extraction process releases dust and particulate matter, which negatively affects air quality and the respiratory health of nearby communities and wildlife. Additionally, the machinery and vehicles used in the process are often powered by fossil fuels, emitting pollutants such as nitrogen oxides and sulfur dioxide, contributing to air pollution and potential long-term environmental damage.

The chemical residues from the extraction process can also contaminate the soil, seeping into the ground and harming plant life. This contamination can lead to reduced soil fertility, decreased agricultural productivity, and damaged local ecosystems.

The global demand for lithium has skyrocketed due to its critical role in battery production for renewable energy and electric vehicles. However, the harsh reality is that traditional lithium mining practices are not sustainable or environmentally friendly. The quest for a greener future is being undermined by outdated and harmful mining methods, and there is an urgent need to explore alternative extraction methods to reduce the environmental toll of lithium production.

Nuclear Bomb Blasts: Pollution and Fallout Effects

You may want to see also

Soil degradation

Lithium is a key component of modern "green" batteries. The demand for lithium has been increasing exponentially, with the lithium-ion battery industry expected to grow from 100 gigawatt hours of annual production in 2017 to almost 800 gigawatt hours in 2027. This demand is driven by the push for electric vehicles and renewable energy storage solutions. However, the proliferation of lithium in the environment, particularly in global agricultural soil, is a rising concern.

Lithium mining has a significant environmental footprint, and the extraction process can cause soil degradation and harm. In its traditional form, lithium mining is not sustainable. The process of extracting lithium from brine evaporation ponds requires large quantities of water, with approximately 500,000 gallons of water used per metric ton of lithium. This has led to water scarcity and depletion in regions with lithium mining operations, such as South America's lithium fields, affecting local communities and farmers.

The use of large amounts of water in lithium extraction also contributes to pollution. Poorly lined evaporation ponds can contaminate near-surface freshwater aquifers. Additionally, there is a potential for chemical spills and contamination during the extraction process, as well as the release of toxic compounds into the soil. Lithium mining generates waste products that can further contaminate the soil and lead to biodiversity loss and damage to ecosystem functions.

Lithium itself is an emerging environmental contaminant. While little is known about its specific contamination characteristics in soil, studies have shown that lithium treatment significantly impacts soil properties and enzyme activities. For example, lithium treatment increases the content of ammonium nitrogen, total nitrogen, and exchangeable potassium, while decreasing nitrate nitrogen and sulfate content.

The improper processing and disposal of spent lithium-ion batteries also contribute to soil degradation. When batteries are carelessly disposed of, they can leach their contents into the surrounding soils, infiltrating deeper layers and polluting the groundwater. This leads to the release of hazardous pollutants, including vapors, gases, metal nano-oxides, and degradation products of the electrolyte, which pose a serious threat to both wildlife and humans.

Overall, while lithium plays a crucial role in the transition to cleaner energy solutions, its extraction and disposal processes have adverse effects on soil health and the environment. It is essential to address these challenges and explore more sustainable and ethical alternatives to ensure the safe implementation of lithium in the living environment.

Cement's Dark Side: Pollution and Its Environmental Impact

You may want to see also

Waste generation

The production of lithium batteries also results in the emission of carbon dioxide and other greenhouse gases. For instance, producing a 1,100-pound battery can emit over 70% more CO2 than manufacturing a traditional car in Germany. The global demand for lithium is expected to increase, which will lead to a corresponding rise in waste generation. This includes the production of large quantities of mineral waste, which can have detrimental effects on human health and the environment.

The end-of-life (EoL) of lithium-ion batteries (LIBs) is a critical issue that needs to be addressed. Currently, there is a lack of standardised waste management practices for spent LIBs, and improper disposal methods can result in toxic pollutants being released into the air, water, and soil. This poses a significant threat to both the environment and human health. LIB waste management is a complex issue that requires collaboration between governments, manufacturers, and waste management specialists to develop sustainable solutions.

In the United States, the Environmental Protection Agency (EPA) has recognised the challenges posed by LIB waste and has hosted workshops to address the increasing risk of fires from end-of-life lithium-ion batteries. The EPA is working with various stakeholders, including battery recyclers, waste managers, and government officials, to develop strategies for improving the collection, recycling, and safe disposal of LIBs.

While recycling can help reduce the environmental impact of LIB waste, it is not without its challenges. The recycling process can generate toxic gases and waste solutions, and there is a need to establish standardised practices to ensure the safe and effective recycling of LIBs. Additionally, the carbon footprint associated with lithium mining and the energy-intensive nature of the extraction process contribute to the overall waste generation and environmental impact of the industry.

Plants and Pollution: The Unseen Impact

You may want to see also

Frequently asked questions

Yes, lithium mining and extraction can cause air pollution. The process releases dust and particulate matter, which negatively affects the respiratory health of nearby communities and wildlife. Additionally, machinery and vehicles powered by fossil fuels emit pollutants such as nitrogen oxides and sulfur dioxide, contributing to air pollution and potential long-term environmental damage.

Lithium mining has a significant environmental footprint. It can harm soil quality, cause water scarcity, and lead to habitat destruction. The process also requires substantial energy, with crushing, grinding, and chemical separation processes demanding vast amounts of electricity, often sourced from non-renewable fossil fuels.

Lithium-ion and lithium-polymer batteries, commonly found in consumer electronic products, may contribute to environmental pollution and adverse human health impacts due to potentially toxic materials. These toxic metals, such as cobalt, copper, nickel, and lead, can leach into the environment and pose risks to human health, especially in regions lacking solid waste management infrastructure.

Lithium mining can have a significant impact on water resources. The extraction process requires large amounts of water, with approximately 500,000 gallons of water used per metric ton of lithium. This high water consumption can lead to water scarcity and impact local communities, as seen in Chile's Salar de Atacama, where mining activities consumed 65% of the region's water.

Exploring alternatives to traditional lithium mining is crucial for ensuring a more sustainable future. Direct Lithium Extraction (DLE) technologies aim to reduce water consumption and pollution by avoiding brine evaporation. Sodium-ion batteries are another option, as sodium ions can be extracted from seawater, making them more abundant and potentially cheaper. Embracing circular economy principles and innovative extraction methods can also help reduce pollution and minimize waste generation.