Hydroelectric power is a renewable energy source that provides substantial benefits for our climate, health, and economy. However, it is important to consider the environmental impacts of hydroelectric facilities, which can include flooding large areas of land, affecting wildlife, and causing noise pollution. While external noise pollution from hydroelectric power plants may not significantly impact community noise levels, high noise levels within the plants due to machinery can pose occupational health risks for workers. This paragraph will discuss the topic of noise pollution in relation to hydroelectric power generation and evaluate its potential effects on surrounding communities and plant workers.

| Characteristics | Values |

|---|---|

| Do hydroelectric power plants cause noise pollution? | Experiments show that external noise pollution is not a hazard to community noise levels. However, noise production is high due to machinery such as turbines, air compressors, and rotors. |

| Impact on occupational health | The high level of noise production makes the work environment unsuitable regarding occupational health. |

| Noise mapping | Noise maps are a key tool to manage noise pollution. |

| Impact on aquatic ecosystems | Hydroelectric facilities can have a major impact on aquatic ecosystems, including injuring and killing fish and other organisms through direct contact with turbine blades. |

| Environmental impact of flooding land | Flooding land for a hydroelectric reservoir can have an extreme environmental impact, including destroying forests, wildlife habitats, agricultural land, and scenic lands. |

What You'll Learn

- Hydroelectric power plants can produce high levels of noise due to machinery

- Noise pollution is a health hazard for workers in these plants

- Noise maps are a key tool to manage noise pollution

- Environmental noise data focuses on occupational noise due to the risk to auditory health

- Large-scale hydroelectric projects can cause flooding, destroying forests and wildlife habitats

Hydroelectric power plants can produce high levels of noise due to machinery

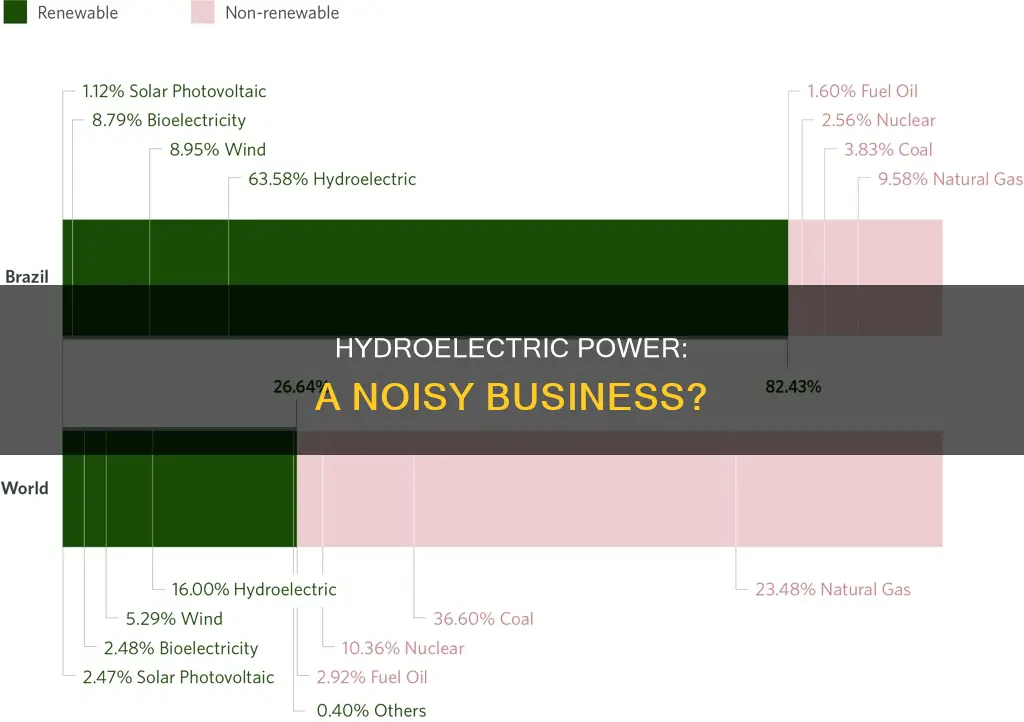

While hydroelectric power is a renewable energy source that provides benefits for the climate, health, and the economy, it can also contribute to noise pollution. This is particularly true in the case of large-scale hydroelectric dams, which are still being constructed in several parts of the world, including China and Brazil.

Hydroelectric power plants can produce high levels of noise due to the extensive machinery involved. The noise generated by turbines, air compressors, and rotors associated with each generating unit can lead to elevated sound levels. The presence of multiple Francis turbines within a power plant contributes significantly to the overall noise levels. These turbines, along with other machinery, result in high noise production, making the work environment unsuitable from an occupational health perspective.

A study conducted in Brazil analyzed sound pressure levels near the machinery in hydroelectric power plants. It selected plants with similar types and ages, each housing 3 to 4 Francis turbines, and found that the noise levels exceeded the limits recommended by current legislation. This indicates that a comprehensive plan with multiple control measures is necessary to effectively mitigate the noise pollution.

The impact of noise pollution on nearby communities and the natural environment cannot be overlooked. While external noise from hydroelectric power plants may not significantly affect community noise levels, the high levels of noise within the plants themselves pose occupational health risks. Additionally, in areas with sensitive ecosystems, such as the Amazon rainforest, the construction of large hydroelectric plants can lead to deforestation and the displacement of local communities, further exacerbating the negative consequences of noise pollution.

To address noise pollution, noise maps have been developed for specific cities, such as Belém in Brazil, based on environmental noise measures from various districts. These maps are crucial tools for managing and mitigating noise pollution, as they facilitate the diagnosis of urban noise issues and help implement targeted solutions. However, it is important to recognize that the accuracy of noise maps relies heavily on the quality and specificity of input data, which should consider the unique geographic and social characteristics of the city being studied.

Air Pollution's Impact: Soil Erosion Explained

You may want to see also

Noise pollution is a health hazard for workers in these plants

While hydroelectric power provides substantial benefits for the climate, economy, and health, it is not without its drawbacks. Hydroelectric facilities can have a significant impact on aquatic ecosystems, and the construction of reservoirs can lead to environmental and community disruption. Additionally, noise pollution in hydroelectric power plants poses a health hazard to workers.

Noise pollution is a significant issue in hydroelectric power plants due to the large amount of machinery in operation, including turbines, air compressors, and rotors. This machinery generates a high level of noise, making the work environment potentially harmful to occupational health. High noise levels can lead to various health issues, including hearing damage, stress, and cardiovascular problems.

A study on noise evaluation in hydroelectric power plants in Brazil analysed sound pressure levels close to the machinery. The selected power plants had 3 to 4 Francis turbines each, and their powerhouses were either sheltered or underground. The study found that the noise produced by the machinery was high enough to make the work environment unsuitable in terms of occupational health.

To address the issue of noise pollution in hydroelectric power plants, comprehensive noise mapping is essential. Noise maps help extend and facilitate the diagnosis of noise pollution and can be created using various geographic and social characteristics of the area being studied. However, it is important to note that the accuracy of noise map results heavily relies on the input data used.

In addition to noise mapping, several control measures can be implemented to mitigate noise pollution in hydroelectric power plants. These measures may include sound insulation, noise barriers, and regular maintenance of machinery to ensure it operates quietly and efficiently. By combining multiple control measures, a more effective strategy for protecting worker health can be achieved.

Overall, noise pollution in hydroelectric power plants is a serious concern that requires careful management. By recognising the potential health hazards and implementing appropriate measures, workers' health and well-being can be protected, and the benefits of hydroelectric power can be enjoyed without compromising occupational safety.

Power Plants: Air Polluters or Not?

You may want to see also

Noise maps are a key tool to manage noise pollution

While experiments in environmental noise from hydroelectric power plants have shown that external noise pollution is not a community hazard, noise production is still high due to the amount of machinery involved. This makes the work environment unsuitable regarding occupational health.

The creation of noise maps involves the use of specialised noise monitoring equipment and sensors strategically placed throughout urban areas. This allows for the gathering of real-time data on traffic noise patterns and their effects on public health and quality of life. By using noise maps, authorities can identify noise hotspots, areas of concern, and noise-sensitive zones. This information is crucial for designing effective noise mitigation strategies, such as implementing zoning laws, soundproofing, sound barriers, low-noise road surfaces, and increasing green spaces.

Noise maps are also essential for industries, construction sites, and urban planners to ensure compliance with legal noise limits set by environmental agencies. They provide a detailed understanding of noise levels in a specific area, helping to identify sources of noise pollution and impacted areas. With this information, effective measures can be taken to reduce noise levels for the benefit of the environment and communities. Additionally, with the development of smart cities, noise mapping is being integrated into real-time monitoring systems, enabling cities to respond dynamically to noise pollution.

Air Pollutants: Understanding Their Diverse Sources

You may want to see also

Environmental noise data focuses on occupational noise due to the risk to auditory health

While studies have shown that hydroelectric power plants do not contribute to community noise levels, the noise generated within them poses a risk to occupational health. The large amount of machinery, such as turbines, air compressors, and rotors, associated with each generating unit, results in high noise production.

Noise maps are essential tools for managing noise pollution, but their accuracy depends on the geographic and social characteristics of the specific location. Urban environments, with road traffic and aircraft noise, can contribute to both occupational and residential noise exposure, increasing the risk of cardiovascular diseases (CVDs). The relative risk for developing coronary heart disease is significantly higher for noise-exposed workers.

To address these issues, various mitigation strategies and preventive measures can be implemented. The WHO has recommended guidelines for environmental noise exposures in the European Region, suggesting specific limits for road traffic, railway, aircraft, and wind turbine noise levels. These guidelines aim to reduce the adverse health effects of noise pollution on individuals and communities.

Plastic Bags: Environmental Polluters or Convenient Necessity?

You may want to see also

Large-scale hydroelectric projects can cause flooding, destroying forests and wildlife habitats

While hydropower is the world's top provider of renewable energy, producing 16% of the global energy supply, it is not without its environmental costs. Large-scale hydroelectric projects can have a significant impact on the environment, particularly when it comes to flooding land to create reservoirs. The size of the reservoir created by a hydroelectric project depends on the size of the generators and the topography of the land. Hydroelectric plants in flat areas tend to require much more land than those in hilly areas or canyons. For example, the large Balbina hydroelectric plant in Brazil flooded 2,360 square kilometers of land, equivalent to the size of Delaware, and only provides 250 MW of power. In contrast, a small 10 MW run-of-the-river plant in a hilly location can use as little as 2.5 acres.

The flooding of land for a hydroelectric reservoir can have severe environmental consequences, including the destruction of forests, wildlife habitats, agricultural land, and scenic areas. This can lead to the loss of carbon sinks, damage to fisheries, and a negative impact on local economies that depend on these resources. Additionally, the water behind the reservoir can become stagnant, resulting in higher levels of sediments and nutrients that promote excessive algae and aquatic weed growth. This, in turn, can crowd out other river animal and plant life and must be controlled through manual harvesting or by introducing fish that feed on these plants.

The construction and dismantling of hydroelectric power plants can also contribute to global warming emissions, particularly in tropical areas or temperate peatlands. After the area is flooded, the vegetation and soil decompose, releasing carbon dioxide and methane. The cumulative impacts of multiple hydropower dams can be significantly greater than the sum of their direct impacts, with even a small dam capable of blocking fish passage and displacing wildlife.

To mitigate these impacts, it is essential to site and operate hydroelectric projects in a responsible manner that protects the natural environment and the interests of local communities. While hydropower can provide valuable renewable energy, it is crucial to balance its development with the preservation of healthy rivers and ecosystems.

Electric Oil Radiators: Do They Pollute Indoor Air?

You may want to see also

Frequently asked questions

Hydroelectric power plants can cause noise pollution due to the amount of machinery used, such as turbines, air compressors, and rotors. However, some studies have shown that external noise pollution from these plants is not a significant hazard to community noise levels.

The number and type of machinery, such as turbines, air compressors, and rotors, contribute to high noise production in hydroelectric power plants.

Yes, high noise levels in the work environment of hydroelectric power plants can pose risks to occupational health and auditory health.

Yes, noise maps and prediction models can help manage and mitigate noise pollution from these plants. Additionally, implementing various measures jointly rather than relying on a single control measure can be more effective in reducing noise levels.

No, the environmental impact of hydroelectric power plants can vary depending on their size, location, and other factors. For example, a large plant in a flat area may have a more significant impact on noise and other environmental factors than a small plant in a hilly location.