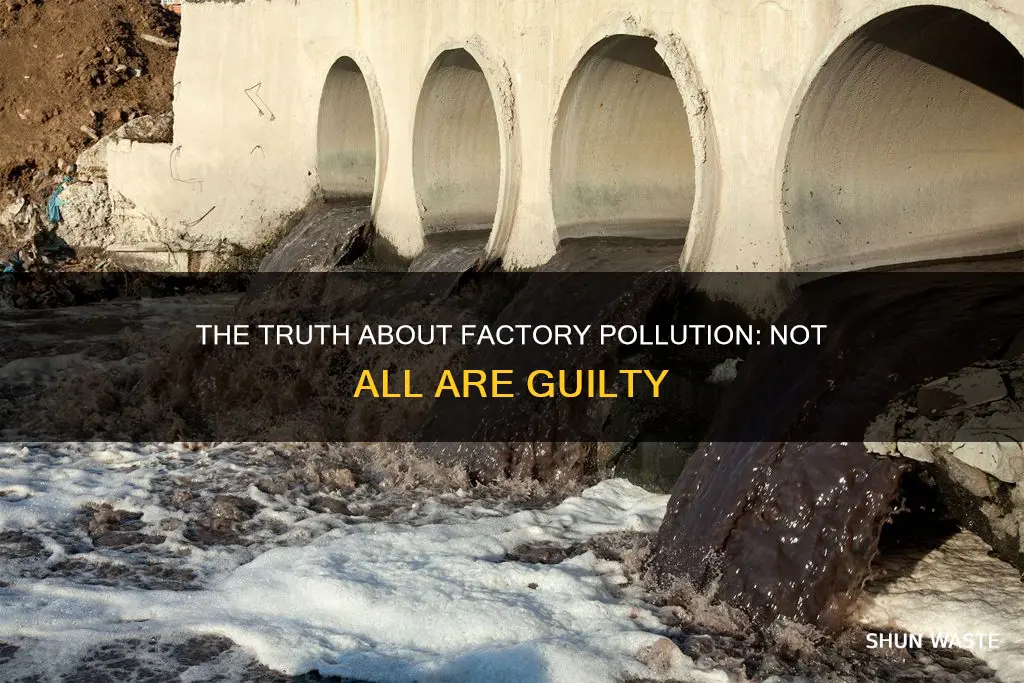

Factories are a major contributor to pollution across the globe. While not all factories are responsible for this, many pollute the water, air and land. This can include smokestack emissions, acidifying rain, chemical spills, greenhouse gases and toxic waste disposal. In some countries, the dumping of hazardous waste is highly regulated, but this is not the case in much of the world.

| Characteristics | Values |

|---|---|

| Water pollution | Illegal dumping of contaminated water, gases, chemicals, heavy metals or radioactive materials into major waterways |

| Air pollution | Smokestack emissions, acidifying rain, chemical spills, greenhouse gases |

| Land pollution | Toxic waste disposal, chemical spills |

| Soil pollution | Industrial wastes being thrown into landfills |

What You'll Learn

- Water pollution: factories dump contaminated water, gases, chemicals, heavy metals and radioactive materials into waterways

- Soil pollution: industrial waste in landfills can destroy soil fertility, decrease crop productivity and contaminate food

- Air pollution: smokestack emissions, acidifying rain, chemical spills, greenhouse gases and toxic waste disposal lower air quality

- Animal waste: concentrated animal feeding operations (CAFOs) produce gases like methane and ammonia, and bacteria like E. coli that can contaminate water

- Land pollution: hazardous waste from factories can be dumped directly into the water table, polluting the land

Water pollution: factories dump contaminated water, gases, chemicals, heavy metals and radioactive materials into waterways

Factories are a major contributing factor to water pollution across the globe. Not all factories are responsible for this, but those in less regulated parts of the world will dump their toxic waste into oceans or rivers. This includes contaminated water, gases, chemicals, heavy metals and radioactive materials.

Water pollution from factories can also be caused by animal waste from CAFOs (concentrated animal feeding operations). These are highly industrialised factories used to produce meat or dairy products in large quantities. The waste from CAFOs often ends up in the water table, contaminating streams and lakes with harmful bacteria like E. coli.

In some countries, the dumping of hazardous waste is highly regulated. However, National Geographic reports that 70% of all industrial pollution is dumped directly into the water table. This means that even when regulations are in place, they are not always effective at preventing water pollution.

The impact of water pollution from factories extends beyond the immediate damage to marine life and the environment. Pollutants can spread beyond the factory, and chemicals and toxic materials can destroy the fertility of the soil, decrease the productivity of crops, and even contaminate the food we consume.

Human Impact: Root Cause of Environmental Woes

You may want to see also

Soil pollution: industrial waste in landfills can destroy soil fertility, decrease crop productivity and contaminate food

Not all factories are responsible for pollution, but those in less regulated parts of the world will dump their toxic waste into oceans or rivers. This waste can also be thrown into landfills, which can cause soil pollution. Industrial waste in landfills can destroy soil fertility, decrease crop productivity and contaminate food. This is because the chemicals and toxic materials can enter the soil and eventually the food chain.

Factories are a major contributing factor to water pollution across the globe. They can pollute water sources directly through the dumping of pollutants into streams and lakes. In some countries, the dumping of hazardous waste is highly regulated, but this is not the case in much of the world. National Geographic reports that 70% of all industrial pollution is dumped directly into the water table.

Factories also cause air pollution, particularly animal factories, or concentrated animal feeding operations (CAFOs). These factories produce gases like methane and ammonia that lower air quality and are harmful to health. The animal waste that CAFOs produce often ends up in the water table, contaminating streams and lakes with harmful bacteria like E. coli. The waste can also seep into groundwater through the soil when it is then used in farm fields as fertiliser.

Geothermal Power: Clean Energy or Polluting Problem?

You may want to see also

Air pollution: smokestack emissions, acidifying rain, chemical spills, greenhouse gases and toxic waste disposal lower air quality

Factories are a major contributing factor to air pollution. While not all factories are responsible for pollution, many are. The main ways in which factories contribute to air pollution are through smokestack emissions, acidifying rain, chemical spills, greenhouse gases and toxic waste disposal.

Smokestack emissions are often the first thing people think of when it comes to factory pollution. Smokestacks emit gases and chemicals into the atmosphere, which can spread beyond the factory and lower the quality of the air.

Acidifying rain is another result of smokestack emissions. When these emissions mix with water vapour in the atmosphere, they create acid rain. This can have devastating effects on the environment, as it did in the UK in the 1960s and 1970s.

Chemical spills are another way in which factories contribute to air pollution. These can occur during the manufacturing process, or when chemicals are being transported to and from the factory.

Factories also contribute to the emission of greenhouse gases, which are a major driver of climate change. Greenhouse gases in the atmosphere trap heat from the sun, leading to global warming.

Finally, the illegal dumping of toxic waste is another way in which factories contribute to air pollution. This often occurs in less regulated parts of the world, where factories can dispose of their waste in oceans or rivers much more cheaply than disposing of it responsibly. This toxic waste can also end up in the soil, destroying its fertility and decreasing crop productivity.

Fossil Fuels: Pollution and Climate Change Culprits

You may want to see also

Animal waste: concentrated animal feeding operations (CAFOs) produce gases like methane and ammonia, and bacteria like E. coli that can contaminate water

Factories are a major contributing factor to water pollution across the globe. Not all factories are responsible for this, but those in less regulated parts of the world will dump their toxic waste into oceans or rivers.

Animal factories, or concentrated animal feeding operations (CAFOs), are a particular kind of factory that causes a great deal of air, land and water pollution. These factories produce gases like methane and ammonia, and bacteria like E. coli that can contaminate water.

CAFOs are highly industrialised and used to produce meat or dairy products in large quantities. The animal waste that CAFOs produce often ends up in the water table, contaminating streams and lakes with harmful bacteria. The waste can also seep into groundwater through the soil when it is then used in farm fields as fertiliser.

In some countries, the dumping of hazardous waste is highly regulated, but this is not the case in much of the world. National Geographic reports that 70% of all industrial pollution is dumped directly into the water table.

Sochi Olympics: Pollution Legacy and Environmental Impact

You may want to see also

Land pollution: hazardous waste from factories can be dumped directly into the water table, polluting the land

Not all factories cause pollution, but those that do are a major contributing factor to water pollution across the globe. This is often due to the illegal dumping of contaminated water, gases, chemicals, heavy metals or radioactive materials into major waterways, which causes damage to marine life and the environment as a whole.

A particular kind of factory called an animal factory, or a concentrated animal feeding operation (CAFO), causes a great deal of air, land and water pollution. These factories produce gases like methane and ammonia that lower air quality and are harmful to health. The animal waste that CAFOs produce often ends up in the water table, contaminating streams and lakes with harmful bacteria like E. coli.

Gasoline Evaporation: What Toxic Fumes Are Released?

You may want to see also

Frequently asked questions

No, not all factories cause pollution. However, those in less regulated parts of the world are more likely to.

Factories can cause pollution through smokestack emissions, acidifying rain, chemical spills, greenhouse gases, and toxic waste disposal.

Factories can cause air, land, and water pollution.

A concentrated animal feeding operation (CAFO) is a type of factory that produces meat or dairy products in large quantities and causes a great deal of pollution.

Pollution from factories can damage marine life and the environment as a whole. It can also decrease the productivity of crops and contaminate food that we may eventually consume.

![Emission reduction Q & A-3R practice field manual of the factory (2003) ISBN: 4879732516 [Japanese Import]](https://m.media-amazon.com/images/I/51A4WbNKK4L._AC_UL320_.jpg)