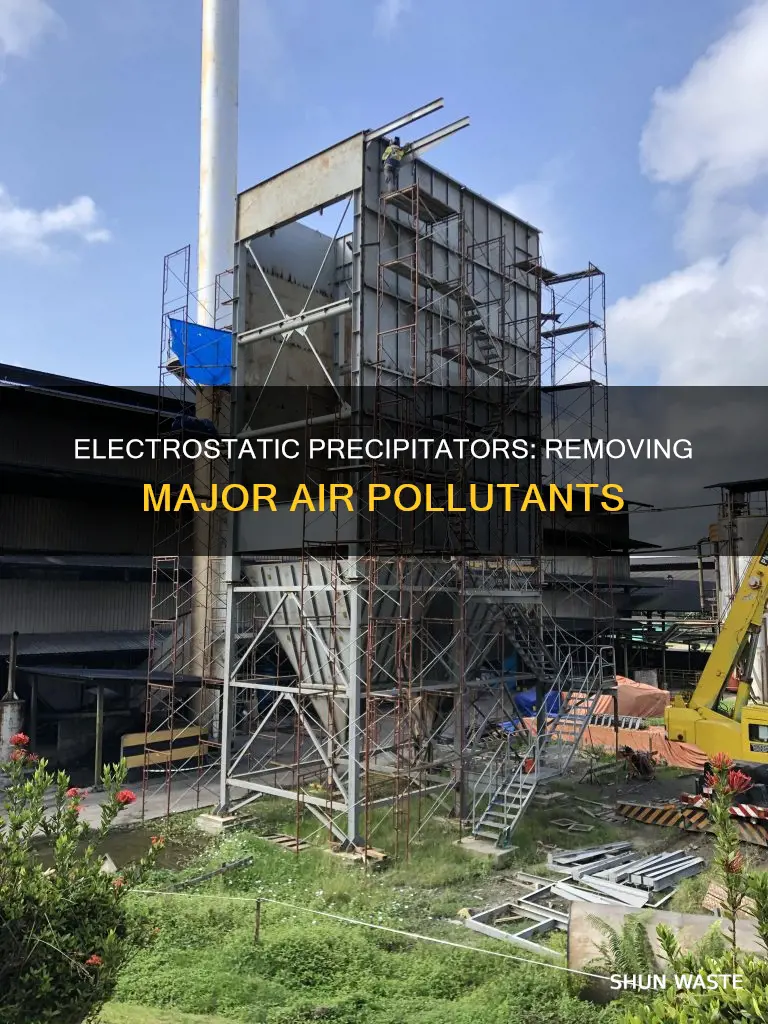

Electrostatic precipitators are devices that remove particulate matter from power-plant smokestack emissions. They are not designed to remove gaseous pollutants such as sulfur dioxide, lead, ozone, or hydrocarbons. In this paragraph, we will explore which major pollutant can be removed with electrostatic precipitators.

| Characteristics | Values |

|---|---|

| Composition | Mixture of solids and aerosols composed of small droplets of liquid, dry solid fragments, and solid cores with liquid coatings |

| Size | Varies widely, but can be less than 10 microns in diameter |

| Shape | Varies widely |

| Chemical composition | May contain inorganic ions, metallic compounds, elemental carbon, organic compounds, and compounds from the earth’s crust |

| Visibility | Particulate matter less than 2.5 microns in diameter is the main cause of reduced visibility (haze) |

| Health effects | Can be inhaled into the lungs and cause serious health problems, including inflammation and damage to the lung tissue |

What You'll Learn

Particulate matter

Electrostatic precipitators are primarily designed to remove particulate matter from power-plant smokestack emissions. They are not designed to remove gaseous pollutants such as sulfur dioxide, lead, ozone or hydrocarbons.

Electrostatic precipitators are a part of industrial pollution control devices. They work by applying a high-voltage charge to particles in the emission stream, which gives them an electric charge. Then, a series of plates with the opposite charge attract the particles, effectively pulling them out of the smokestack emissions and drastically reducing the pollution they would otherwise release into the atmosphere.

Electrostatic precipitators can achieve over a 99% removal efficiency for particulates in industrial settings, highlighting their effectiveness in air pollution control. During coal combustion, for example, electrostatic precipitators can filter out ash and soot, which are types of particulates that can be harmful when released into the atmosphere.

Pollution-Damaged Lungs: Can They Be Healed?

You may want to see also

Not designed for gaseous pollutants

Electrostatic precipitators are not designed to remove gaseous pollutants such as sulfur dioxide, lead, ozone, or hydrocarbons. They are primarily designed to remove particulate matter or particulates from power-plant smokestack emissions. They work by applying a high-voltage charge to particles in the emission stream, which gives them an electric charge. Then, a series of plates with the opposite charge attract the particles, effectively pulling them out of the smokestack emissions and drastically reducing the pollution they would otherwise release into the atmosphere.

Electrostatic precipitators are a part of industrial pollution control devices. They are not designed to remove gaseous pollutants but are highly effective at removing particulate matter. During coal combustion, for example, electrostatic precipitators can filter out ash and soot, which are types of particulates that can be harmful when released into the atmosphere. This significantly reduces the environmental impact of coal-fired power plants. Studies have shown that electrostatic precipitators can achieve over a 99% removal efficiency for particulates in industrial settings, highlighting their effectiveness in air pollution control.

Fracking's Impact: Drinking Water Pollution and Its Prevention

You may want to see also

How they work

Electrostatic precipitators are primarily designed to remove particulate matter from power-plant smokestack emissions. They are not designed to remove gaseous pollutants such as sulfur dioxide, lead, ozone, or hydrocarbons.

Electrostatic precipitators work by applying a high-voltage charge to particles in the emission stream, which gives them an electric charge. Then, a series of plates with the opposite charge attract the particles, effectively pulling them out of the smokestack emissions and drastically reducing the pollution they would otherwise release into the atmosphere.

The process begins by passing the emissions through a high-voltage electric field, which charges the particulate matter. After being charged, the particles are attracted to collection plates that have an opposite charge, pulling the pollutants out of the emissions before they are released into the atmosphere. This process is highly effective, with studies showing that electrostatic precipitators can achieve over a 99% removal efficiency for particulates in industrial settings.

Electrostatic precipitators are a vital part of industrial pollution control devices. They are particularly useful during coal combustion, where they can filter out ash and soot, which are types of particulates that can be harmful when released into the atmosphere. By removing these solid particles from emissions, electrostatic precipitators help to significantly reduce the environmental impact of coal-fired power plants and improve the health outcomes for the surrounding environment.

Mineral Extraction: Environmental Pollution and Impacts

You may want to see also

Power-plant smokestack emissions

Electrostatic precipitators are primarily designed to remove particulate matter from power-plant smokestack emissions. They are not designed to remove gaseous pollutants such as sulfur dioxide, lead, ozone, or hydrocarbons.

Electrostatic precipitators are a type of industrial pollution control device. They work by applying a high-voltage charge to particles in the emission stream, which gives them an electric charge. A series of plates with the opposite charge then attract the particles, effectively pulling them out of the smokestack emissions and reducing the pollution that would otherwise be released into the atmosphere.

Particulate matter, or particulates, are solid particles that can be harmful when released into the atmosphere. During coal combustion, for example, electrostatic precipitators can filter out ash and soot, which are types of particulates. This significantly reduces the environmental impact of coal-fired power plants. Studies have shown that electrostatic precipitators can achieve over a 99% removal efficiency for particulates in industrial settings, highlighting their effectiveness in air pollution control.

It is important to note that while electrostatic precipitators are effective at removing particulate matter, they are not designed to remove all types of pollutants. Gaseous pollutants, such as sulfur dioxide, lead, ozone, and hydrocarbons, are not effectively removed by electrostatic precipitators. Therefore, it is crucial to combine electrostatic precipitators with other pollution control measures to ensure the comprehensive mitigation of power-plant smokestack emissions.

Genetic Diversity: Fly Population's Defense Mechanism Against Pollution

You may want to see also

Environmental impact

Electrostatic precipitators are a vital tool in reducing air pollution. They are designed to remove particulate matter from power-plant smokestack emissions. Particulate matter is a type of air pollutant that includes ash and soot, which are released during coal combustion.

Electrostatic precipitators work by applying a high-voltage charge to particles in the emission stream, giving them an electric charge. The charged particles are then attracted to a series of plates with the opposite charge, effectively pulling them out of the smokestack emissions. This process drastically reduces the amount of pollution that would otherwise be released into the atmosphere. Studies have shown that electrostatic precipitators can achieve over a 99% removal efficiency for particulates in industrial settings.

It is important to note that electrostatic precipitators are not designed to remove gaseous pollutants such as sulfur dioxide, lead, ozone, or hydrocarbons. These pollutants are released from power plants and other industrial sources and can have significant environmental and health impacts. However, by removing particulate matter, electrostatic precipitators can still significantly reduce the environmental impact of power plants, leading to cleaner air and improved health outcomes for surrounding communities.

Overall, electrostatic precipitators play a crucial role in mitigating air pollution and protecting the environment. Their ability to efficiently remove solid particles from emissions highlights their effectiveness in air pollution control and their potential to improve environmental health.

Noise Pollution: Hearing Loss Culprit?

You may want to see also

Frequently asked questions

Electrostatic precipitators are devices that use electrical charges to attract and collect particles.

Electrostatic precipitators remove particulate matter from power-plant smokestack emissions.

Particulate matter is solid particles, such as ash and soot, which are released during coal combustion.

Electrostatic precipitators cannot remove gaseous pollutants, such as sulfur dioxide, lead, ozone or hydrocarbons.

Electrostatic precipitators work by passing emissions through a high-voltage electric field, which charges the particulate matter. The charged particles are then attracted to collection plates with the opposite charge, pulling the pollutants out of the emissions.