Dissolved oxygen (DO) is a measure of the amount of oxygen molecules dissolved in water. Oxygen plays a key role in many industries, including wastewater treatment and aquaculture systems, and can have a significant impact on the chemical, biological, and ecological processes within these systems. While oxygen is essential for the survival of aquatic plants and animals, it can also be a harmful substance, leading to corrosion in boilers and pipes in power plants. To prevent this, several methods can be employed to remove oxygen from water, including mechanical and chemical processes. Some common techniques for removing dissolved oxygen include boiling water, nitrogen purging, and the use of chemical scavengers such as sodium sulfite and hydrogen sulfide.

| Characteristics | Values |

|---|---|

| Techniques to remove dissolved oxygen (DO) from water | Boiling water at 1 atm, boiling water under reduced pressure, nitrogen (N) purging, sonication under reduced pressure, nitrogen stripping, and "coupling techniques" |

| Factors that affect DO levels | Human activities (e.g. clearing land, runoff, sewage waste), natural factors (e.g. water conditions such as salinity and temperature, aquatic organisms), and weather conditions |

| Role of DO in groundwater quality | Supports bacteria that break down pollutants and minimizes harmful substances like iron and manganese |

| Use of DO measurements | Monitoring water quality, ensuring optimal conditions in bioreactors, and various industrial applications |

| Impact of low DO concentrations | Can affect aquatic ecosystems, leading to illnesses and even death |

| Chemical methods for removing DO | Addition of sulfur dioxide, sodium sulfite, or hydrazine, and use of oxygen scavengers |

What You'll Learn

Nitrogen stripping

Oxygen is a crucial factor in many industries, including wastewater treatment and aquaculture systems, as it can cause dramatic shifts in chemical, biological, and ecological processes. For instance, oxygen supports the bacteria that break down pollutants and minimizes harmful substances like iron and manganese. However, oxygen can also be a harmful substance, leading to corrosion in boilers and pipes in power plants, which can be prevented by removing oxygen.

The process of nitrogen stripping involves blowing air through the wastewater to remove volatile gases such as hydrogen sulfide, hydrogen cyanide, and ammonia. This is a transfer from a liquid phase to a gas phase. The basic principle of nitrogen removal involves introducing air into the water, creating a reaction with the ammonia molecules, which are then converted into a less toxic and less soluble form of nitrogen gas. The nitrogen gas is then released into the atmosphere, thereby reducing the levels of ammonia in the water.

While nitrogen stripping is highly effective, it can be expensive due to the large amounts of nitrogen gas required. This has prompted the exploration of new methods to reduce nitrogen gas usage in the oxygen removal process. One such method is the use of a rotor-stator reactor (RSR), which combines nitrogen stripping with vacuum degassing to achieve higher efficiency in removing dissolved oxygen from water.

How Much of Water's Plastic Pollution Comes from Land?

You may want to see also

Boiling water

During the thermal gassing process, water is placed into a conical flask and boiled for 30 minutes on a hot plate in the open air. The water in the flask is then slowly poured into a bottle (usually plastic). Before the cap is tightly screwed onto the bottle, any remaining air is squeezed out of the bottle. With the cap tightly screwed on the bottle, it is then cooled under running tap water. This method is the least effective way to remove DO from water.

It is worth noting that, as soon as boiled water begins to cool off, it starts to reabsorb oxygen. By the time it has returned to room temperature, it will contain significant amounts of oxygen. If you want to maintain the water in a degassed state, right after boiling it, you should store it in a bottle that has been filled as close to the cap as possible, and screw the cap on tightly.

While overboiling water (like for several minutes at a rolling boil) will undoubtedly remove dissolved air and make tea taste flat, removing the water from the heat promptly at boiling will probably allow for so little gas extraction as to be unnoticeable to taste.

Other common techniques to remove DO from water include boiling water under reduced pressure, nitrogen (N) purging, and sonication under reduced pressure. However, the most effective way to remove DO from water is via nitrogen stripping.

Water Pollution's Deadly Impact: Miscarriage Risk

You may want to see also

Purging with nitrogen gas

Nitrogen purging is often used to remove oxygen from water in various industrial applications. For example, in oilfield waters, the presence of dissolved oxygen increases the corrosion rate of steel. Therefore, nitrogen purging is employed to protect steel pipes and process equipment. Similarly, in power plants, removing oxygen from boilers and pipes is essential to prevent corrosion and improve heat transfer, increasing efficiency.

The process of nitrogen purging involves using nitrogen gas to displace and remove oxygen from the water. This can be done through different methods, such as displacement purging and dilution purging, depending on the complexity of the system. In displacement purging, nitrogen gas is introduced at high or low pressure, thrusting a scraping piston (or pig) through the line to purge unwanted matter, including oxygen. This method is ideal for manufacturing equipment with basic cross-sections, such as pipelines.

Dilution purging, on the other hand, is more suitable for complex systems with cross-sections, such as columns, reactors, or kilns. In this method, nitrogen gas is mixed with the specific gas to be purged, and the mixture is purged from the entry point to the exit point. This process dilutes and displaces unwanted substances, creating a more inert atmosphere. Nitrogen purging is also used in food packaging and to prevent explosions in tanks containing hydrocarbon liquids by eradicating the vapor space.

Nonpoint Source Water Pollution: Three Key Examples Explained

You may want to see also

Using oxygen scavengers

Oxygen scavengers are used to remove or decrease oxygen levels in enclosed packaging, boiler feedwater, and other applications. They are commonly used to maintain product safety, extend shelf life, and prevent corrosion in boiler systems. The specific oxygen scavenger used depends on factors such as the intended use, water activity, and other specific requirements.

Oxygen scavengers work by reacting with oxygen to remove it from the system. The most widely used material for oxygen scavenging in water treatment is sodium sulfite, which is highly effective and suitable for low to medium-pressure boilers. It is usually supplied as a catalysed product, with cobalt enhancing its reactivity, especially at lower temperatures and pressures. Other common oxygen scavengers include hydrazine, which is highly effective but toxic and corrosive, and ethylene diamine tetraacetic acid (EDTA), which is a less toxic and corrosive chelating agent that binds oxygen and removes it from the solution.

In boiler systems, oxygen scavengers are used to prevent corrosion, reduce maintenance costs, and avoid equipment failure. The use of a scavenger depends on factors such as the size and type of the boiler, water quality, and budget constraints. For example, a simple mechanical deaerator may be sufficient for a small boiler with good water quality, while a large boiler or poor water quality may require a chemical oxygen scavenger in addition to a mechanical deaerator. It is important to consult with a qualified technician to determine the appropriate oxygen removal method and ensure compatibility with other chemicals in the system.

Oxygen scavengers are also used in steam boilers to remove oxygen from the feedwater, which is the water used to operate the boilers. The temperature of the feedwater influences the selection of the oxygen scavenger and the dose rate for the chosen product. Higher temperatures are generally preferred, but this depends on the specific boiler and feedwater setup. Some oxygen scavengers, such as sodium sulfite, produce solids that contribute to total dissolved solids (TDS), resulting in higher water loss during blowdown. Low solids oxygen scavengers, such as tannin, DEHA (diethylhydroxylamine), or carbohydrazide, can be used to mitigate this issue.

Oxygen scavengers can also be used in oilfield waters to protect steel pipe and process equipment from corrosion caused by dissolved oxygen. The reaction of dissolved oxygen with hydrogen sulfide and added chemical scavengers has been studied, with natural waters found to influence the reaction rate. Sulfur dioxide or sodium sulfite can be used to remove dissolved oxygen, but the presence of certain ions and other chemicals can impact the reaction kinetics.

Ways to Combat Water Pollution

You may want to see also

Human activities

Agricultural practices, including the use of fertilizers and pesticides, contribute to water pollution. Fertilizers increase algae growth, which, in turn, raises oxygen demand during respiration at night. When algae die, microorganisms use oxygen for their decomposition, leading to a decline in dissolved oxygen. This process, known as eutrophication, is accelerated by human activities, resulting in oxygen-deficient conditions that can be detrimental to aquatic life.

Industrial activities also play a role in DO depletion. Improperly disposed wastewater from industrial plants can introduce toxic chemicals such as lead, mercury, and chromium into water bodies. Additionally, some industries release organic chemicals that require oxygen for decomposition, leading to oxygen depletion if not adequately treated.

Residential practices, such as the use of residential fertilizers and the improper disposal of waste, can also impact DO levels. Nutrient runoff from fertilizers can increase algae and macrophyte growth, affecting oxygen levels. Organic matter, including animal wastes and landfill waste, can further increase oxygen demand as they are decomposed by bacteria and fungi.

Other human activities, such as channel alteration and impoundments, can physically alter water bodies and impact DO levels. These alterations can reduce water turbulence and slow water velocities, decreasing the incorporation of oxygen via aeration and diffusion. Additionally, seasonal changes and temperature increases associated with human activities can impact DO concentrations, with warmer water holding less oxygen than colder water.

In summary, various human activities, including agricultural, residential, and industrial practices, directly and indirectly contribute to the removal of oxygen from water. These activities introduce pollutants, excess nutrients, and organic matter, disrupting the delicate balance of aquatic ecosystems and leading to oxygen depletion, which can have significant impacts on aquatic life and ecosystem health.

Air Pollution's Impact on Drinking Water Sources

You may want to see also

Frequently asked questions

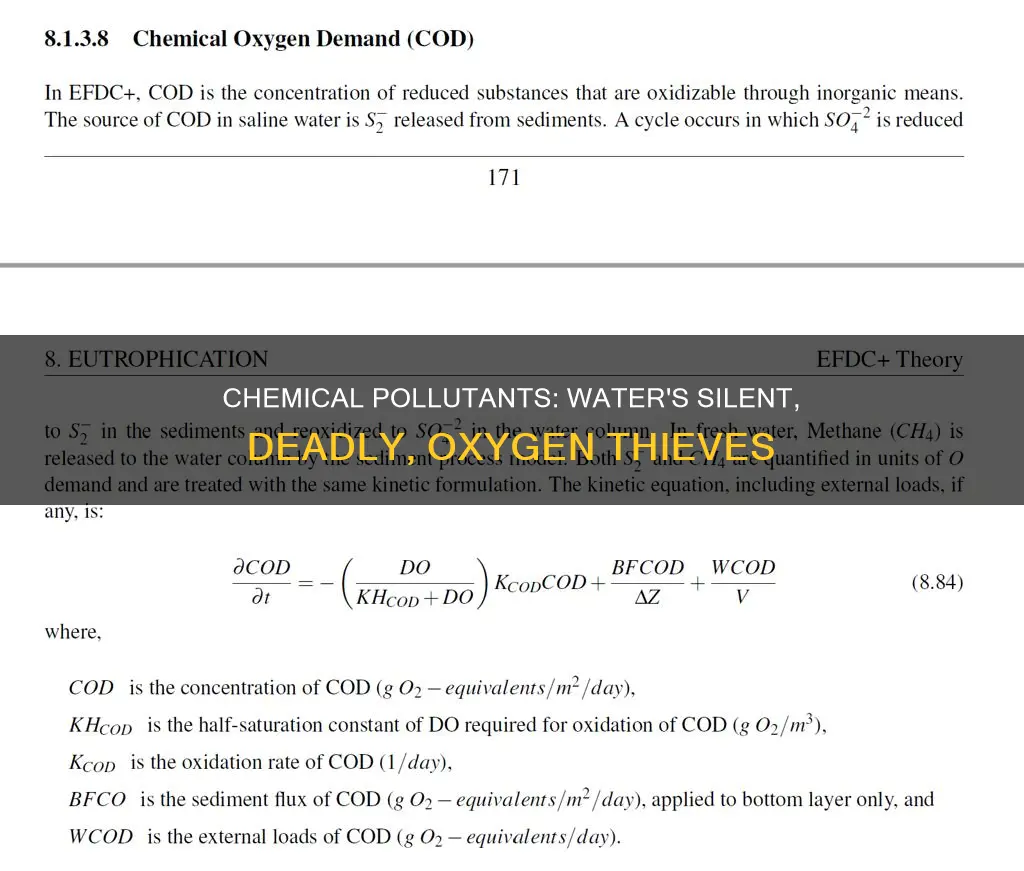

Chemical pollutants that remove oxygen from water are called oxygen scavengers. Some examples include sodium sulfite, sulfur dioxide, and hydrazine.

Aquatic plants and animals require oxygen to survive. A decrease in oxygen levels can affect aquatic communities and ecosystems, leading to illnesses and even death.

Natural factors that affect dissolved oxygen (DO) levels include water conditions such as salinity and temperature, and the number of aquatic organisms present.

Human activities such as clearing land, sewage waste, and agricultural and urban runoff can alter DO levels in water. For example, excess nutrients and organic matter from sewage waste can be decomposed by microorganisms, reducing the amount of oxygen in the water.

There are both physical and chemical methods to remove dissolved oxygen from water. Chemical methods involve the addition of a reducing agent, such as sodium sulfite or sulfur dioxide. Physical methods include boiling water, nitrogen purging, and thermal degassing.