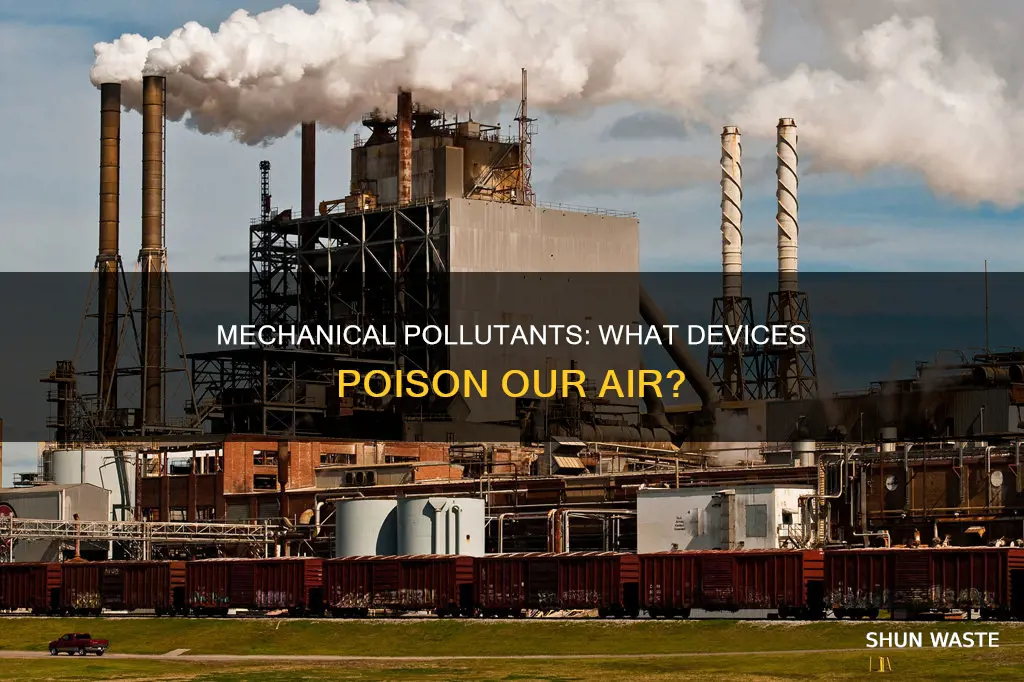

Mechanical devices that contribute to air pollution are found in nearly every stage of the industrial process, from raw material sourcing to product manufacturing, maintenance, repair, and distribution. Examples of air pollution control devices include electrostatic precipitators, fabric filters, scrubbers, incinerators, and more. These devices work to prevent a variety of different gaseous and solid pollutants from entering the atmosphere, primarily from industrial smokestacks.

| Characteristics | Values |

|---|---|

| Air pollution control devices | Electrostatic precipitators, fabric filters, scrubbers, incinerators, mist collectors, air filters, inertial separators, cyclones, water scrubbing devices, ceramic filters |

| Function | Capture and remove particulate matter, dust, moisture, vapour, smoke, oil mist, liquid droplets, dry particulates, contaminants, pollen, microbes, chemicals, hazardous emissions, gases, acidic gases, nitrogen oxides, heavy metals, mercury |

| Mechanism | Use of filtration media, such as fabric, sintered metal, or ceramic; electrostatic precipitation; high static electrical potential differences; baffles; discharge and collection electrodes; dust clean-out systems; collecting plates and hoppers; water; combustion; incineration; thermal oxidation; chemical scrubbing; adsorption; fuel changes; oxygenated compounds; low excess air; staged combustion; low NOx burners; water injection; oxyfuel combustion; exhaust gas recirculation (EGR); reburn; fluidized bed combustion |

| Applications | Residential, commercial, and industrial settings; industrial smokestacks; industrial emissions and exhaust streams; industrial exhaust gases; flue gas; boiler exhaust |

What You'll Learn

Industrial processes and machinery

One such device is the electrostatic precipitator (ESP), which captures and removes particulate matter, such as dust, from industrial emissions and exhaust streams. ESPs use high static electrical potential differences to charge the particles, which are then attracted to oppositely charged collection plates. Over time, the collected material is removed either by mechanical means or by using water to wash off the particles.

Another type of air pollution control technology is fabric filtration, which includes pulsejet and mechanical bag filter units. Fabric filters are highly effective and versatile, using fans to draw or push particulate-laden gas through the cloth. Mist collectors, or moisture eliminator filters, are another device used to remove moisture and vapour from gas streams, such as smoke, oil mist, and other liquid droplets. These filters are particularly effective in capturing submicron liquid particles.

To control gaseous chemical contaminants, there are technologies such as biofiltration, incineration/thermal oxidation, chemical scrubbing devices, and adsorption. Scrubbers, for example, are systems that remove hazardous pollutants from industrial exhaust gases, particularly gaseous pollutants like SOx, before they are released into the environment. Incineration is another method that converts VOC emissions into carbon dioxide and water through combustion.

When selecting an air pollution control system, it is important to consider various factors, including the analysis of chemicals involved, the evaluation of the existing exhaust system, and the exhaust stream pre-cooling.

Fast Fashion's Air Pollution: The Unseen Cost of Style

You may want to see also

Electrostatic precipitators

The basic design of an electrostatic precipitator consists of discharge electrodes and collecting plates. As gas streams pass through the discharge electrodes, the particles within the stream become ionized and electrically charged. These charged particles are then attracted to the oppositely charged collecting plates, where they are deposited and removed from the airstream. Over time, the collected particles accumulate on the plates and are periodically removed through mechanical means, such as shaking the plates, or by using water to wash off the particulates. This process is known as precipitation, giving rise to the name "electrostatic precipitators".

The efficiency of electrostatic precipitators is impressive, with some models achieving control efficiencies of up to 99% for particulate matter that is 1.0 micron or larger in diameter. However, it's important to note that particles with very high or very low resistivity can be challenging for these devices to handle effectively. Factors such as temperature, airflow, and specific resistance also play a role in affecting the efficiency of the precipitators.

Air Pollution Accountability: Who's Responsible?

You may want to see also

Fabric filters

Air pollution control devices are a set of devices that work to keep a range of gases and solid pollutants out of the atmosphere. Fabric filters, also known as dust collectors, are a popular method for removing particulate matter from a gas stream due to their high effectiveness and versatility. They are one of the two most commonly used air pollution control devices, the other being electrostatic precipitators.

Large fabric filters are often constructed of tubular surfaces arranged so that flow is from the outside of the tube to the inside of the tube. There are three main types of bag filters. The simplest and cheapest type of unit operates with a velocity of about 0.01 m/s across the bag surface. The second type is more sophisticated and robust and incorporates some form of automatic bag-shaking mechanism, which may be operated by mechanical, vibratory, or air-pulsed methods. The third type is the reverse-jet filter, which can deal with high dust concentrations at high efficiencies in an economic and compact unit.

The cleaning process for fabric filters can be done by a pulse jet, reversed air, or mechanical vibration. In pulse jet cleaning, a short air blast travels along the fabric cloth, shaking the dust from the cloth surface. In reverse air cleaning, the filtering action is stopped and a flow of air is sent in the opposite direction, separating the dust layer from the cloth. In small filters, the dust separation can be done by mechanically displacing the top of the filter cloth tube. Mechanical devices are the least favoured as their use often shortens the lifetime of the fabric material.

Calculating Malaysia's Air Pollutant Index: A Step-by-Step Guide

You may want to see also

Scrubbers

Wet scrubbers are air pollution control systems that use a liquid to remove contaminants from a gas stream. They are particularly effective in removing high-humidity gases and sticky particles. Hot gases are also handled easily, with gases cooled at the collector inlet. Wet scrubbers can remove organic and inorganic pollutants, including those that cause illness, deplete the ozone, or disrupt ecosystems. They are also used to remove inorganic gases, odors, fumes, chrome, NOx, coarse, fine and ultrafine particulate, mercury and other heavy metals, HCl, Cl2, SO2, and HF.

Wet scrubbers work by absorbing pollutants with water or a water-based solvent. The contaminated gas enters at the bottom and passes upward through the packed bed and downward-flowing solvent sprays. The pollutants are collected in the solvent droplets, and before the gas leaves the scrubber, it passes through a mist eliminator to capture any droplets. The mist eliminator collects and removes the contaminated droplets from the solvent. An effective mist eliminator is a fundamental component of any wet scrubber.

Wet scrubbers come in several configurations, including spray-tower scrubbers, orifice scrubbers, wet-impingement scrubbers, and venturi scrubbers. In a spray-tower scrubber, an upward-flowing airstream is washed by water sprayed downward from a series of nozzles. The water is recirculated after it is cleaned to prevent clogging of the nozzles. Spray-tower scrubbers can remove 90% of particulates larger than about 8 μm. Venturi scrubbers are the most efficient of the wet collectors, achieving efficiencies of more than 98% for particles larger than 0.5 μm in diameter.

Candle Conundrum: Do They Pollute Indoor Air?

You may want to see also

Incineration

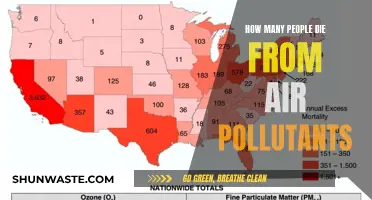

The incineration process releases various pollutants into the air, including particulate matter, oxides of nitrogen, oxides of sulfur, carbon monoxide, heavy metals like lead and mercury, and organic compounds such as dioxins and furans. These pollutants can have detrimental effects on both the environment and human health. Inhalation of these pollutants can lead to respiratory issues and other health complications.

To mitigate the negative impact of incineration on air quality, modern incineration facilities are equipped with advanced air pollution control devices (APCDs). These devices are designed to capture and remove pollutants before they are released into the atmosphere. Examples of such devices include electrostatic precipitators, fabric filters, and wet scrubbers. Electrostatic precipitators use electrical charges to attract and collect particulate matter, such as dust and smoke, from industrial emissions. Fabric filters, on the other hand, use cloth filtration to remove particulate matter from gas streams, while wet scrubbers use water sprays to cool and remove hazardous pollutants from industrial exhaust gases.

Additionally, environmental regulations have played a significant role in reducing emissions from incineration facilities. Regulatory bodies monitor key incineration process conditions, including waste feed rates, combustion temperatures, and gas residence times, to ensure compliance with standards. Computerized systems are also employed to automatically control combustion temperatures and cut off waste feeds if operating conditions become unsafe. These measures help ensure that incinerators operate under optimal conditions to minimize the release of harmful pollutants.

While incineration has been a common method for waste management, the pollution it causes is a growing concern. With the implementation of advanced air pollution control devices and stricter environmental regulations, the impact of incineration on air quality can be significantly reduced. However, it is crucial to continuously improve and innovate these technologies to protect the environment and human health from the potential harmful effects of incineration.

Air Pollution's Impact on Global Warming

You may want to see also

Frequently asked questions

Any device that emits pollutants during combustion can be considered a mechanical device that pollutes the air. This includes industrial machinery, vehicles, and residential heating systems.

Air pollution control devices are a set of devices that work to keep a range of gases and solid pollutants out of the atmosphere.

The two main categories are devices that manage particulate emissions and devices that control acidic gas emissions.

Examples include fabric filtration, electrostatic precipitators, inertial separators, water scrubbing devices, and ceramic filters.

Examples include biofiltration, incineration/thermal oxidation, chemical scrubbing devices, and adsorption.