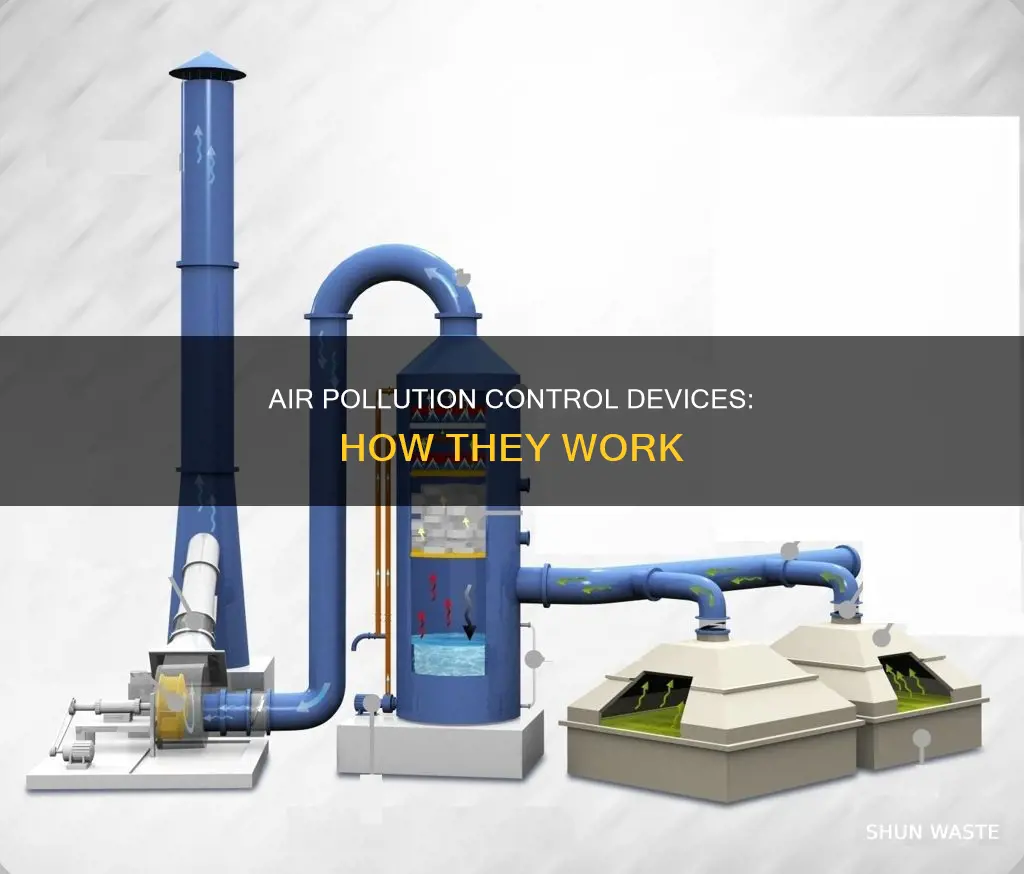

Air pollution control devices are a series of devices that work to prevent gaseous and solid pollutants from entering the atmosphere, primarily from industrial smokestacks. These devices are designed to remove particulate and gaseous pollutants from emissions of stationary sources, including power plants and industrial facilities. They are essential in industries such as woodworking, metal fabrication, cement production, pharmaceuticals, food processing, and agriculture. Common types of equipment for collecting fine particulates include cyclones, scrubbers, electrostatic precipitators, and baghouse filters. These devices can be separated into two broad categories: devices that control the amount of particulate matter escaping into the environment and devices that control acidic gas emissions.

| Characteristics | Values |

|---|---|

| Purpose | To reduce or eliminate the emission of substances that can harm the environment or human health |

| Types | Cyclone collectors, electrostatic precipitators, fabric filters, scrubbers, thermal oxidizers, mist collectors, selective catalytic reduction systems, air filters, baghouses, dust collection systems, carbon capture and storage |

| Factors influencing selection | Type of pollutant, control efficiency, temperature tolerance, resistance to corrosive materials, process compatibility, pollutant characteristics (e.g., corrosivity, reactivity, shape, density, size, and size distribution) |

| Function | Capture, collect, convert, or combust pollutants |

| Effectiveness | Depends on the percentage of emissions the device can collect, control, reduce, or eliminate |

Scrubbers

There are two main types of scrubbers: wet scrubbers and dry scrubbers. Wet scrubbers use a scrubbing liquid or solvent to remove contaminants from the air. Water is the most common solvent, but other solutions can be used to target specific compounds. Wet scrubbers can be designed in several ways, including spray tower scrubbers, orifice scrubbers, and venturi scrubbers. Spray tower scrubbers use a series of nozzles to spray water or another liquid downward, washing an upward-flowing airstream. Venturi scrubbers are the most efficient of the wet scrubbers, achieving efficiencies of more than 98% for particles larger than 0.5 μm in diameter.

Dry scrubbers, on the other hand, do not saturate the flue gas stream with moisture. They are used to remove acid gases, primarily from combustion sources. Dry scrubbers can be designed as dry sorbent injectors (DSIs) or spray dryer absorbers (SDAs). Spray dryer absorbers introduce flue gases into an absorbing tower where they come into contact with an atomized alkaline slurry. The acid gases are absorbed and react to form solid salts, which are then removed.

Wet scrubbers are highly effective at removing a wide range of pollutants, including organic and inorganic pollutants, and are often used to minimize environmental impact and human safety risks. They are particularly useful for removing harmful inorganic gases, such as chromic acid, hydrogen sulfide, and sulfur dioxide, as well as volatile organic compounds (VOCs) from the air.

Air Pollution: The Looming Crisis in the US

You may want to see also

Fabric filters

Air pollution control devices are a series of devices that work to prevent a variety of different pollutants, both gaseous and solid, from entering the atmosphere, primarily from industrial smokestacks. Fabric filters, also known as baghouses, are one such device. They are a fairly simple method of removing dust and particulate matter from gas streams using filter bags.

There are several types of fabric filters, including mechanical shakers, reverse air, and pulse jet. Mechanical shakers, as the name suggests, mechanically shake the bags to remove the dust. Reverse air fabric filters collect dust on the inside of the bags, and as the dust cake builds up and cuts off the inflow of dirty air, a reverse flow of clean air is used to remove the dust, causing the bags to partially collapse. Pulse jet fabric filters use short bursts of compressed air to clean the bags of dust buildup, and this can be done while the filter is still in operation.

A more sophisticated version of the fabric filter incorporates an automatic bag-shaking mechanism, which may be operated by mechanical, vibratory, or air-pulsed methods. A heavier fabric allows for higher face velocities and permits operation under more difficult conditions. The reverse-jet filter is a type of bag filter that can deal with high dust concentrations at high efficiencies in a compact unit.

Air Pollution Indicators: Understanding the Vital Signs

You may want to see also

Dust collectors

Air pollution control devices are a series of devices that work to prevent a variety of pollutants, both gaseous and solid, from entering the atmosphere, primarily from industrial smokestacks. Dust collectors are critical air pollution control devices that capture fine dust, powders, metal shavings, wood chips, and other airborne particles, improving air quality and protecting human health.

Baghouse collectors are highly effective at removing dust from the air, even when dust particles are tiny. They utilize cylindrical air filter fabrics to collect and remove dust and are suitable for high-volume dry dust collection applications. Cyclones use centrifugal force to separate, collect, and remove dry particulate matter from the air and are suitable for high-volume dust collection involving heavier dust and higher temperatures. They are different from other dust collectors as they do not use filters to collect the dust. Instead, the gas undergoes some vortex motion so that the gas acceleration is centripetal, and the particles move centrifugally towards the outside of the cyclone.

Pulse jet cleaning dust collectors are used for continuous-duty dust collection applications, while unit collectors are small and self-contained, consisting of a fan and some form of dust collector. They are suitable for isolated, portable, or frequently moved dust-producing operations. Wet dust collectors utilize liquid-gas or gas-liquid solutions to collect and remove solid and water-soluble gas pollutants and are suitable for explosive dust collection applications.

Overall, dust collectors play a crucial role in maintaining air quality and protecting human health in a variety of industries.

Air Pollution: Where is it Worst?

You may want to see also

Oxidizers

There are several types of oxidizers, each with unique characteristics and applications:

- Thermal Oxidizers: These are combustion systems that operate at high temperatures, typically between 1400°F and 1500°F. They are designed to oxidize hydrocarbon-based pollutants into CO2 and H2O, utilizing the principles of time, temperature, and turbulence for effective performance. Thermal oxidizers can be customized to handle high VOC concentrations and are commonly used in petrochemical and chemical airstream applications.

- Catalytic Oxidizers: These oxidizers use catalysts to facilitate the oxidation process, reducing the required temperature for the reaction to occur.

- Regenerative Thermal Oxidizers (RTOs): RTOs are designed to recycle heat from the facility's exhaust processing, using alternating heating and cooling patterns to break down VOCs and HAPs. They are known for their energy efficiency and are often more cost-effective than other types of oxidizers.

- Direct Fired Oxidizers: This type of oxidizer utilizes direct flame or thermal oxidation to treat exhaust gases. They are commonly used in applications where high temperatures and rapid oxidation are required.

The selection of a specific type of oxidizer depends on various factors, including the nature of the pollutants, airflow characteristics, and the unique requirements of the industry. Oxidizers play a crucial role in air pollution control, ensuring that harmful compounds are converted into less toxic byproducts, contributing to a cleaner environment and improved human health.

Gaya's Air Pollution: Causes and Concerns

You may want to see also

Electrostatic precipitators

Air pollution control devices are a series of devices that work to prevent various pollutants, both gaseous and solid, from entering the atmosphere, especially from industrial smokestacks. These devices can be categorised into two types: devices that control the amount of particulate matter escaping into the environment, and devices that control acidic gas emissions.

ESPs use static electricity to remove soot and ash from exhaust fumes before they exit the smokestacks. The basic design consists of a row of thin vertical wires and a stack of large flat vertical metal plates. The plates are spaced anywhere from 0.5 inches to 7 inches apart, depending on the application. The wires carry a large negative DC voltage, and the particles are electrically charged as they pass by, then migrate through the electrostatic field to a grounded collection electrode. The treated air then passes out of the precipitator and through a stack to the atmosphere.

There are four basic types of ESPs: plate and wire (dry), flat plate (dry), wet, and two-stage. Wet electrostatic precipitators (WESPs) are used to collect finer particulate matter than dry ESPs and are also used to collect aerosols. They are commonly used to remove liquid droplets, including oil, resin, tar, and sulfuric acid mist, from gas streams in industrial settings. Dry electrostatic precipitators, on the other hand, operate above the dew point of the gas stream to remove impurities from smoke and dust.

Air Pollution in Asia: A Deadly Premature Killer

You may want to see also

Frequently asked questions

Air pollution control devices are a series of devices that work to prevent various pollutants, both gaseous and solid, from entering the atmosphere, primarily from industrial smokestacks.

There are several types of air pollution control devices, each with unique pollutant removal mechanisms. The most common and effective solutions include scrubbers, dust collectors, oxidizers, and mist collectors.

Scrubbers are advanced air pollution control devices that remove pollutants from industrial exhaust gases by introducing a scrubbing liquid or sorbent into the exhaust stream. There are two main types of scrubbers: wet scrubbers and dry scrubbers.

Examples of oxidizers include thermal oxidizers, catalytic oxidizers, and regenerative thermal oxidizers (RTOs). These systems use high temperatures in the presence of oxygen to oxidize harmful compounds into non-toxic byproducts such as carbon dioxide and water vapour.

Electrostatic precipitators (ESPs) are air pollution control devices that use static electricity to collect and remove particulate matter, such as dust, from industrial emissions. ESPs use large transformers to produce an electrical potential difference, attracting the particulate matter towards the collection plates.