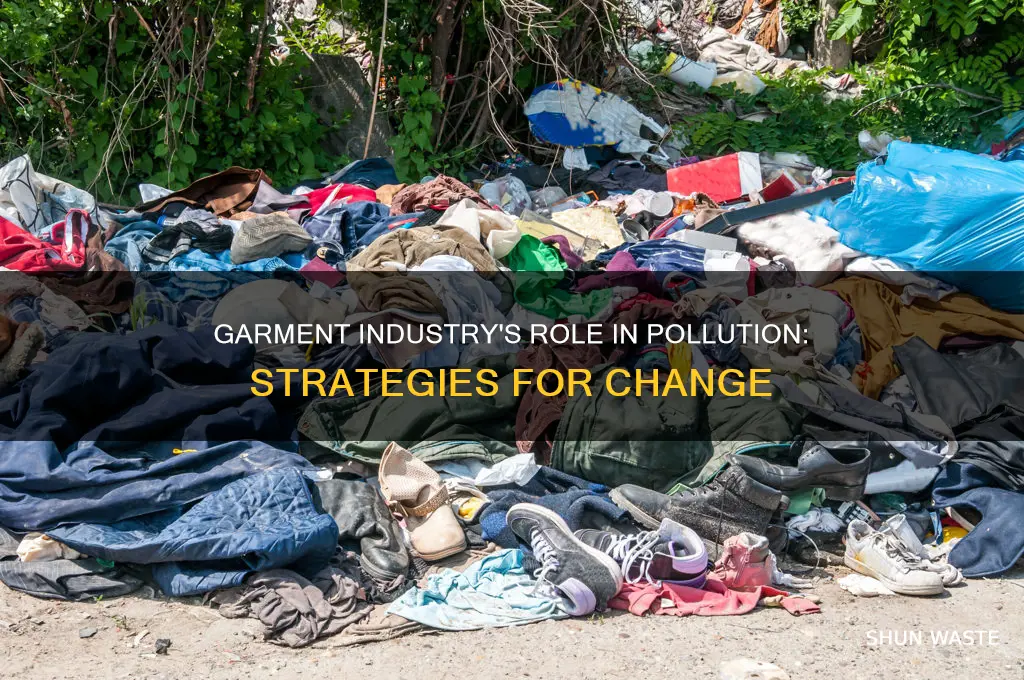

The garment industry is a significant contributor to environmental pollution, from the production and distribution of crops, fibres and garments to the use of apparel and footwear. The fashion industry produces 10% of all carbon emissions and is the second-largest consumer of the world's water supply. To make the industry more sustainable, all actors, from designers to manufacturers, critics and consumers, must get involved.

| Characteristics | Values |

|---|---|

| Water pollution | The garment industry is responsible for about 20% of global clean water pollution from dyeing and finishing products |

| Air pollution | The industry is a significant driver of greenhouse gas emissions |

| Soil pollution | Soil degradation is caused by the production and distribution of crops, fibres, and garments |

| Carbon emissions | The fashion industry produces 10% of all carbon emissions |

| Water consumption | The industry is the second-largest consumer of the world's water supply |

| Microplastics | A single laundry load of polyester clothes can discharge 700,000 microplastic fibres that can end up in the food chain |

| Fast fashion | Promotes many first washes, which release the majority of microplastics from textiles |

| Consumer behaviour | Consumers must become aware of what they buy, asking if the manufacturers used sustainable criteria to make the clothing |

What You'll Learn

Sustainable criteria for manufacturing clothing

The garment industry is a major contributor to environmental pollution, with the production and distribution of crops, fibres, and garments used in fashion all causing water, air, and soil degradation. The fashion industry is responsible for 10% of all carbon emissions and is the second-largest consumer of the world's water supply.

To make the garment industry more sustainable, all actors, from designers to manufacturers, critics, and consumers, must get involved. Consumers should ask if the manufacturers used sustainable criteria to make the clothing. This includes considering quality over quantity, as every additional year a garment is worn means less pollution.

Manufacturers should aim to reduce their carbon emissions and water consumption, as well as look for ways to recycle clothing and reduce waste. They can also use more sustainable materials and processes, such as using less water in the dyeing and finishing of products, and reducing the use of synthetic materials that release microplastics into the environment.

Critics and designers can also play a role in promoting more sustainable practices and raising awareness about the environmental impact of the garment industry. By working together, the industry can reduce its environmental impact and create a more sustainable future.

Burning Plastic Bags: Safe or Polluting?

You may want to see also

Reducing water pollution

The garment industry is a significant contributor to water pollution, with textile production estimated to be responsible for about 20% of global clean water pollution from dyeing and finishing products. The fashion industry is also a major consumer of water, and the production of garments can dry up water sources and pollute rivers and streams.

To reduce water pollution, the garment industry can take several steps. Firstly, manufacturers can adopt more sustainable practices, such as using less water-intensive processes and reducing the use of harmful chemicals in dyeing and finishing products. They can also invest in water treatment technologies to ensure that any wastewater released back into the environment is safe and does not contribute to pollution.

Secondly, designers can create clothing with sustainability in mind. This includes using more eco-friendly materials, such as organic cotton or recycled fabrics, and avoiding the use of harmful chemicals. Designers can also focus on creating timeless pieces that will remain in style for longer, reducing the need for frequent purchases and encouraging consumers to keep their clothing for longer.

Thirdly, consumers play a crucial role in reducing water pollution. By being mindful of their purchases, consumers can help reduce the demand for water-intensive and polluting practices. This includes buying only what they need, choosing quality over quantity, and supporting brands that prioritise sustainability. Consumers can also extend the lifespan of their clothing by repairing and repurposing items, rather than constantly buying new ones.

Finally, collaboration between all actors in the garment industry is essential for reducing water pollution. Manufacturers, designers, critics, and consumers must work together to promote sustainable practices and raise awareness about the environmental impact of the industry. By making conscious choices and advocating for change, the garment industry can significantly reduce its water pollution and contribute to a healthier planet.

Purifying Water: Removing Pollution, Restoring Nature's Balance

You may want to see also

Reducing carbon emissions

The garment industry is responsible for a significant amount of carbon emissions, water pollution, and plastic pollution. To reduce carbon emissions, the garment industry can take several steps:

Firstly, the industry can focus on reducing energy consumption and transitioning to renewable energy sources. This can be achieved by investing in energy-efficient technologies and processes, such as using renewable energy for manufacturing and distribution.

Secondly, the industry can promote sustainable practices throughout the supply chain. This includes using sustainable materials, such as organic or recycled fabrics, and implementing eco-friendly dyeing and finishing techniques to reduce water pollution.

Thirdly, the industry can encourage longer product lifespans by promoting quality over quantity. This can be done by educating consumers about the environmental impact of their purchases and encouraging them to buy fewer, higher-quality garments that will last longer. Additionally, promoting clothing repair, recycling, and donation can help extend the lifespan of garments and reduce the need for new production, thus lowering carbon emissions.

Finally, the industry can collaborate with designers, manufacturers, critics, and consumers to create a more sustainable future. By involving all stakeholders, the industry can develop innovative solutions and drive systemic change. This includes advocating for sustainable criteria in clothing production and raising awareness about the environmental impact of the garment industry.

By implementing these strategies, the garment industry can significantly reduce its carbon emissions and contribute to a greener and more sustainable future.

Thermal Pollution's Impact on Water Quality

You may want to see also

Reducing plastic pollution

The garment industry is a significant contributor to plastic pollution. Textile production is estimated to be responsible for about 20% of global clean water pollution from dyeing and finishing products. A single laundry load of polyester clothes can discharge 700,000 microplastic fibres that can end up in the food chain. The majority of microplastics from textiles are released during the first few washes. Fast fashion is based on mass production, low prices and high sales volumes that promote many first washes. Washing synthetic products leads to the accumulation of more than half a million tonnes of microplastics on the bottom of the oceans every year.

To reduce plastic pollution, the garment industry can take several steps. Firstly, manufacturers can adopt more sustainable practices, such as using sustainable criteria to make clothing and reducing the use of plastic in their products. They can also increase the recycling of clothing to make new clothes, as currently, less than one per cent of clothing is recycled. Designers can create clothing that is built to last, encouraging consumers to buy quality over quantity.

Critics can play a role by raising awareness about the environmental impact of the garment industry and promoting sustainable practices. Consumers can also make a significant difference by being mindful of their purchases. They can ask manufacturers about the sustainability of their products, repair and recycle clothing, and donate unwanted items. By extending the lifespan of garments, consumers can help reduce the demand for new clothing and, consequently, decrease plastic pollution.

Additionally, the garment industry can collaborate with environmental organisations to develop and implement sustainable practices. By working together, they can find innovative solutions to reduce plastic pollution, such as using alternative materials or developing more eco-friendly production methods.

Plastic Pollution: Cancer Risk and Environmental Hazard

You may want to see also

Reducing waste

The garment industry has a significant impact on the environment, contributing to water, air, and soil degradation. To reduce waste, the industry can take several steps:

Firstly, manufacturers should adopt more sustainable practices. This includes using sustainable criteria to make clothing, such as using less water and energy-intensive processes, and reducing the use of harmful chemicals in dyeing and finishing products. By implementing more eco-friendly methods, manufacturers can reduce their environmental footprint and minimise pollution.

Secondly, designers play a crucial role in reducing waste. They can create garments with longevity in mind, prioritising quality over quantity. By designing clothing that is built to last, designers can encourage consumers to purchase fewer items over time, reducing the overall demand for new clothes. Additionally, designers can explore innovative ways to recycle and repurpose old garments, giving them new life instead of ending up in landfills.

Thirdly, consumers have the power to drive change by making conscious choices. Before purchasing, consumers can ask about the sustainability practices of manufacturers and opt for clothing made with eco-friendly materials and processes. Consumers can also extend the lifespan of their garments by repairing, repurposing, or donating them instead of discarding them. Buying only what is necessary and combining garments creatively can also reduce waste significantly.

Lastly, collaboration between all stakeholders is essential. The garment industry comprises various actors, from designers to manufacturers, critics, and consumers. By working together, they can develop and promote sustainable practices throughout the industry. This includes advocating for policy changes, supporting sustainable initiatives, and raising awareness about the environmental impact of the garment industry.

By implementing these measures, the garment industry can significantly reduce waste and minimise its environmental impact. It is crucial to recognise that collective action is required to bring about meaningful change and create a more sustainable future for the industry and the planet.

Cities' Power to Legislate: Air Pollution Laws

You may want to see also

Frequently asked questions

The garment industry is a significant driver of greenhouse gas emissions and plastic pollution. It is responsible for about 20% of global clean water pollution from dyeing and finishing products, and 10% of all carbon emissions.

The industry must work towards sustainability, with all actors involved, from designers to manufacturers, critics, and consumers. Consumers must become aware of what they buy, asking if the manufacturers used sustainable criteria to make the clothing. They should also repair clothing, donate what they no longer use, and buy only what they need.

The pollution generated by garment production has a devastating impact on the health of local people, animals and ecosystems where the factories are located.

![Emission reduction Q & A-3R practice field manual of the factory (2003) ISBN: 4879732516 [Japanese Import]](https://m.media-amazon.com/images/I/51A4WbNKK4L._AC_UL320_.jpg)