Caprolactam is an organic compound with the formula (CH2)5C(O)NH. It is a colourless solid and a lactam (a cyclic amide) of caproic acid. The global demand for this compound is high, with approximately five million tons per year being used to make Nylon 6 filament, fibre, and plastics. The production of caprolactam can result in nitrous oxide as a byproduct, which is a highly potent greenhouse gas. While nitrous oxide emissions from caprolactam production are unregulated in most countries, caprolactam itself was previously listed as a hazardous air pollutant in the US under the Clean Air Act. It was removed from the list of hazardous air pollutants in 1996, with OSHA establishing permissible exposure limits for caprolactam vapour to address the health effects associated with exposure.

| Characteristics | Values |

|---|---|

| Description | Caprolactam (CPL) is an organic compound with the formula (CH2)5C(O)NH. It is a colourless solid lactam (a cyclic amide) of caproic acid. |

| Use | The majority of caprolactam is used to make Nylon 6 filament, fiber, and plastics. |

| Global Demand | Approximately five million tons per year. |

| Hazardous Air Pollutant | Caprolactam was listed as a hazardous air pollutant under the Clean Air Act of 1990. However, it was delisted in 1996. |

| Health Effects | Exposure to caprolactam vapor can cause eye, upper respiratory tract, and skin irritation. High vapor levels occur at elevated temperatures, and exposure can result in a bitter taste in the mouth, nervousness, epistaxis, and upper respiratory tract congestion. |

| Production By-Product | The production of caprolactam can generate nitrous oxide as a by-product, a highly potent greenhouse gas. |

What You'll Learn

- Caprolactam was removed from the list of hazardous air pollutants in 1996

- Caprolactam is an organic compound with the formula (CH2)5C(O)NH

- Caprolactam is a colourless solid at room temperature

- Caprolactam is used to make Nylon 6 filament, fibre, and plastics

- Caprolactam production can result in nitrous oxide as a by-product

Caprolactam was removed from the list of hazardous air pollutants in 1996

Caprolactam, an organic compound with the formula (CH2)5C(O)NH, is a colourless solid lactam (a cyclic amide) of caproic acid. It is predominantly used to make Nylon 6 filament, fibre, and plastics. The Clean Air Act amendments of 1990 initially identified 189 hazardous air pollutants (HAPs) for regulation, and caprolactam was among them. However, in June 1996, the Environmental Protection Agency (EPA) removed caprolactam from the list of HAPs. This decision was published in the Federal Register on June 18, 1996 (61 FR 30816).

The removal of caprolactam from the HAPs list in 1996 was likely influenced by several factors. Firstly, the EPA is responsible for regulating emissions of hazardous air pollutants under the Clean Air Act. Since 1990, the EPA has modified the list through rulemaking, and in the case of caprolactam, it was determined that it no longer met the criteria for a hazardous air pollutant. Additionally, the production processes and emission control technologies for caprolactam may have improved, reducing the overall emissions and associated risks.

Another factor to consider is the health effects associated with caprolactam exposure. While caprolactam vapour can cause eye, upper respiratory tract, and skin irritation, these effects occur primarily at elevated temperatures. With the implementation of exposure limits and safety measures, the risks associated with caprolactam exposure can be mitigated. Furthermore, the EPA's decision to remove caprolactam from the HAPs list may have been based on advancements in scientific understanding and risk assessment methodologies.

It is worth noting that the removal of caprolactam from the list of HAPs does not mean it is no longer regulated or monitored. The EPA continues to have the authority to regulate and set exposure limits for substances, even if they are not on the HAPs list. Additionally, other environmental and health regulations may still apply to caprolactam, ensuring its production and use are managed to minimise potential impacts.

Since the removal of caprolactam from the HAPs list in 1996, the EPA has continued to periodically review and update the list. For example, in 2022, the EPA added 1-bromopropane to the list of HAPs under the Clean Air Act, demonstrating their ongoing commitment to addressing hazardous air pollutants and protecting human health and the environment.

Refineries: The Dark Side of Air Pollution

You may want to see also

Caprolactam is an organic compound with the formula (CH2)5C(O)NH

Caprolactam, an organic compound, is described by the formula (CH2)5C(O)NH. It is a colourless solid lactam (a cyclic amide) of caproic acid. The global demand for this compound is high, at approximately five million tons per year. The majority of caprolactam produced is used to make Nylon 6 filament, fibre, and plastics.

The compound was first described in the late 1800s when it was prepared by the cyclization of ε-aminocaproic acid, which is the hydrolysis product of caprolactam. The world demand for caprolactam was estimated to reach five million tons per year by 2015. Of the caprolactam produced, 90% is used to make filament and fibre, 10% is used for plastics, and a small amount is used as a chemical intermediate.

Due to its commercial importance, numerous methods have been developed for its production. It is estimated that 90% of all caprolactam is synthesised from cyclohexanone, which is first converted to its oxime. Treatment of this oxime with acid induces the Beckmann rearrangement to produce caprolactam. The immediate product of this acid-induced rearrangement is the bisulfate salt of caprolactam, which is then neutralised with ammonia to release the free lactam and cogenerate ammonium sulfate.

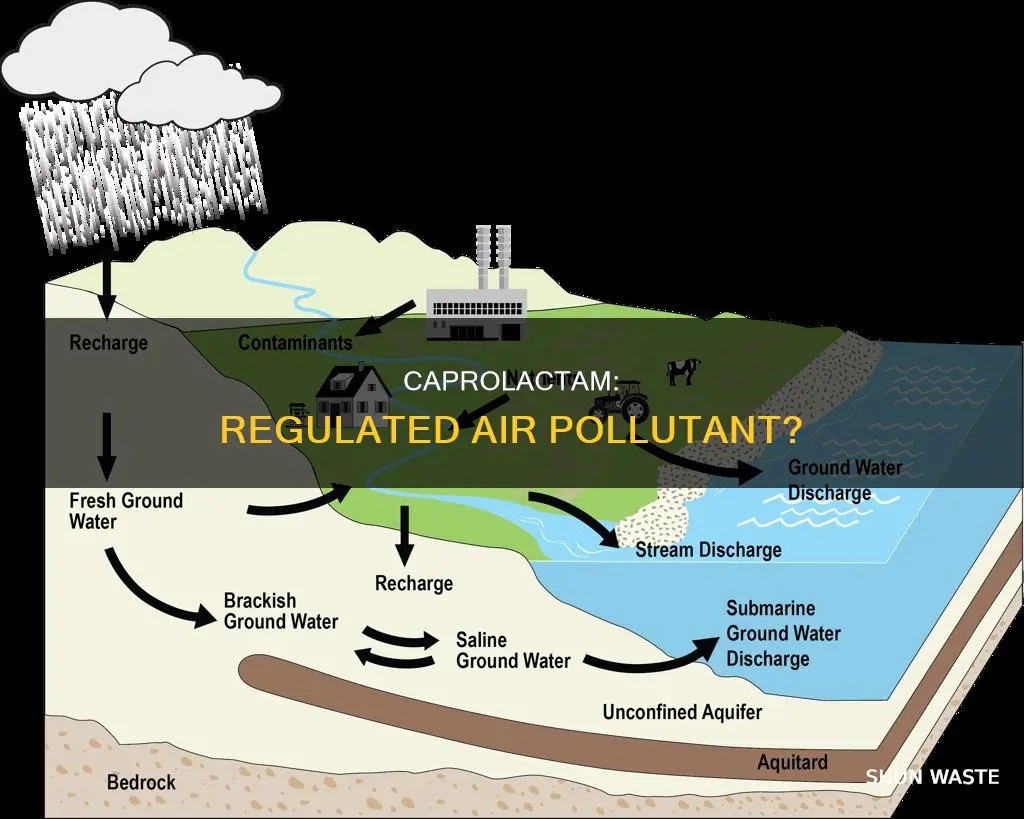

The industrial production of caprolactam can result in nitrous oxide as a by-product, a highly potent greenhouse gas. While nitrous oxide emissions from this process are unregulated in most countries, they can vary significantly depending on the production method and the use of emission abatement technology.

Human-Caused Air Pollution: Impacting Our Environment and Health

You may want to see also

Caprolactam is a colourless solid at room temperature

Caprolactam, an organic compound with the formula (CH2)5C(O)NH, is a colourless solid at room temperature. It is a lactam (a cyclic amide) of caproic acid. The global demand for this compound is high, with an estimated demand of five million tons per year. The majority of caprolactam produced is used to make Nylon 6 filament, fibre, and plastics.

Caprolactam was once considered a hazardous air pollutant. Under the Clean Air Act, the Environmental Protection Agency (EPA) is required to regulate emissions of hazardous air pollutants. The original list included 189 pollutants, and caprolactam was among them. However, in 1996, caprolactam was delisted as a hazardous air pollutant. This decision was made through a rulemaking process, and it is important to note that the EPA has the authority to amend the list as necessary.

The production of caprolactam can result in the release of nitrous oxide as a by-product, which is a highly potent greenhouse gas. The amount of nitrous oxide emitted during caprolactam production can vary significantly depending on the specific processes and technology used. While nitrous oxide emissions from caprolactam production are largely unregulated, some countries, such as Germany, have taken steps to estimate and address these emissions.

Despite being delisted as a hazardous air pollutant, caprolactam can still pose health risks. Exposure to caprolactam vapour can cause eye, upper respiratory tract, and skin irritation. OSHA (Occupational Safety and Health Administration) has established exposure limits for caprolactam vapour to protect workers from these health risks. These limits include a Time-Weighted Average (TWA) of 5 ppm (parts per million) and a Short-Term Exposure Limit (STEL) of 10 ppm.

In summary, caprolactam is a colourless solid at room temperature with various industrial applications. While it is no longer considered a hazardous air pollutant, efforts are made to minimise the production of by-products and to protect workers from potential health risks associated with caprolactam vapour exposure.

Chicago's Air Pollution: A Serious Concern?

You may want to see also

Caprolactam is used to make Nylon 6 filament, fibre, and plastics

Caprolactam is a colourless, odourless solid with the chemical formula (CH2)5C(O)NH. It is a lactam (a cyclic amide) of caproic acid. The global demand for caprolactam is high, estimated at five million tons per year, and it is mainly used to make Nylon 6 filament, fibre, and plastics.

Nylon 6 is a synthetic fibre that is generally white but can be dyed in a solution bath prior to production for different colour results. It has a density of 1.14 g/cm3 and a melting point of 215°C. Nylon 6 is made through the ring-opening polymerization of caprolactam. When caprolactam is heated to about 533 K in a nitrogen atmosphere, the caprolactam ring breaks and undergoes polymerization. The molten mass is then passed through spinnerets to form Nylon 6 fibres.

Caprolactam is the only monomer used in the production of Nylon 6. The process of converting caprolactam to Nylon 6 involves heating caprolactam to around 250°C with 5-10% water. This causes the carbonyl oxygen in caprolactam to react with the water molecule, leading to a series of reactions that result in the formation of Nylon 6.

The commercial significance of caprolactam has led to the development of various production methods. It is estimated that 90% of caprolactam is synthesised from cyclohexanone, which is first converted to its oxime. Another method involves the formation of oxime from cyclohexane using nitrosyl chloride, which is less expensive but accounts for only 10% of world production.

While caprolactam has important industrial applications, its production can result in the emission of nitrous oxide, a highly potent greenhouse gas. These emissions are unregulated in most countries and are not included in the European Union Emissions Trading System. In the past, caprolactam was listed as a hazardous air pollutant by the U.S. Clean Air Act of 1990 but was later removed from the list in 1996.

Air Pollution's Burden: Measuring Exposure's Impact

You may want to see also

Caprolactam production can result in nitrous oxide as a by-product

Caprolactam (CPL) is an organic compound with the formula (CH2)5C(O)NH. It is a colourless solid and a lactam (a cyclic amide) of caproic acid. The global demand for this compound is high, estimated at five million tons per year, with 90% of caprolactam produced being used to make Nylon 6 filament and fibre, and 10% for plastics. The remaining small amount is used as a chemical intermediate in the synthesis of various pharmaceutical drugs.

Due to its commercial significance, numerous methods have been developed for the production of caprolactam. It is estimated that 90% of all caprolactam is synthesised from cyclohexanone, which is first converted to its oxime. The treatment of this oxime with acid induces the Beckmann rearrangement to yield caprolactam. The immediate product of this process is the bisulfate salt of caprolactam, which is then neutralised with ammonia to release the free lactam and cogenerate ammonium sulfate.

The production of caprolactam can result in nitrous oxide as a by-product. Nitrous oxide is a highly potent greenhouse gas, and emissions can vary significantly due to different production processes and inconsistent use of emission abatement technology. The conventional production process of caprolactam can result in the release of nitrous oxide, carbon dioxide, sulfur dioxide, and non-methane volatile organic compounds. While modified processes aim to reduce ammonium sulfate by-products, they still involve NH3 oxidation and consequent nitrous oxide emissions.

Nitrous oxide emissions from caprolactam production are unregulated in most countries and are not included in the European Union Emissions Trading System. However, technologies exist that can abate these emissions, similar to those used in nitric acid nitrous oxide abatement activities. These include secondary and tertiary controls, which reduce nitrous oxide directly after its formation in the oxidation reactor.

Methane's Hazardous Air Pollutant Status: What You Need To Know

You may want to see also

Frequently asked questions

No, caprolactam was removed from the list of hazardous air pollutants in 1996.

Caprolactam (CPL) is an organic compound with the formula (CH2)5C(O)NH. It is a colourless solid and a lactam (a cyclic amide) of caproic acid.

Caprolactam is used to make Nylon 6 filament, fiber, and plastics. 90% of caprolactam produced is used for filament and fiber, while 10% is used for plastics.

Exposure to caprolactam vapor can cause eye, upper respiratory tract, and skin irritation. Workers exposed to the vapor reported a bitter taste in the mouth, nervousness, epistaxis, and upper respiratory tract congestion.

The production of caprolactam can generate nitrous oxide, a potent greenhouse gas, as a byproduct. While nitrous oxide emissions from caprolactam production are unregulated in most countries, the EPA regulates the emission of hazardous air pollutants in the US.