Air pollution is a serious issue that can lead to severe illnesses. While there are commercially available air quality sensors on the market, they can be expensive. Fortunately, it is possible to make your own air pollution detector at home. This device will allow you to determine the air quality in your environment and detect pollutants such as ozone, particulate matter, carbon monoxide, and sulfur dioxide. In this project, we will walk you through the steps to build your own air pollution detector using inexpensive sensors and basic circuitry. By the end of this guide, you should have a functional detector that will help you monitor your exposure to harmful pollutants and take control of your health.

| Characteristics | Values |

|---|---|

| Purpose | To provide a cost-efficient means of determining air quality |

| Focus | Five components of the Environmental Protection Agency's Air Quality Index: ozone, particulate matter, carbon monoxide, sulfur dioxide, and nitrous oxide |

| Additional sensors | Town gas sensor, temperature and humidity sensor |

| Calibration | Against known pollution sources; sensor data sheets and prior research used for approximations |

| Detection method | Infrared LED and a photodetector to measure scattering off small airborne particulates |

| Output | Digital output signals; +5V signal when no particles detected, low-voltage pulse when particles detected |

| Circuitry | Circuit diagram provided in the source |

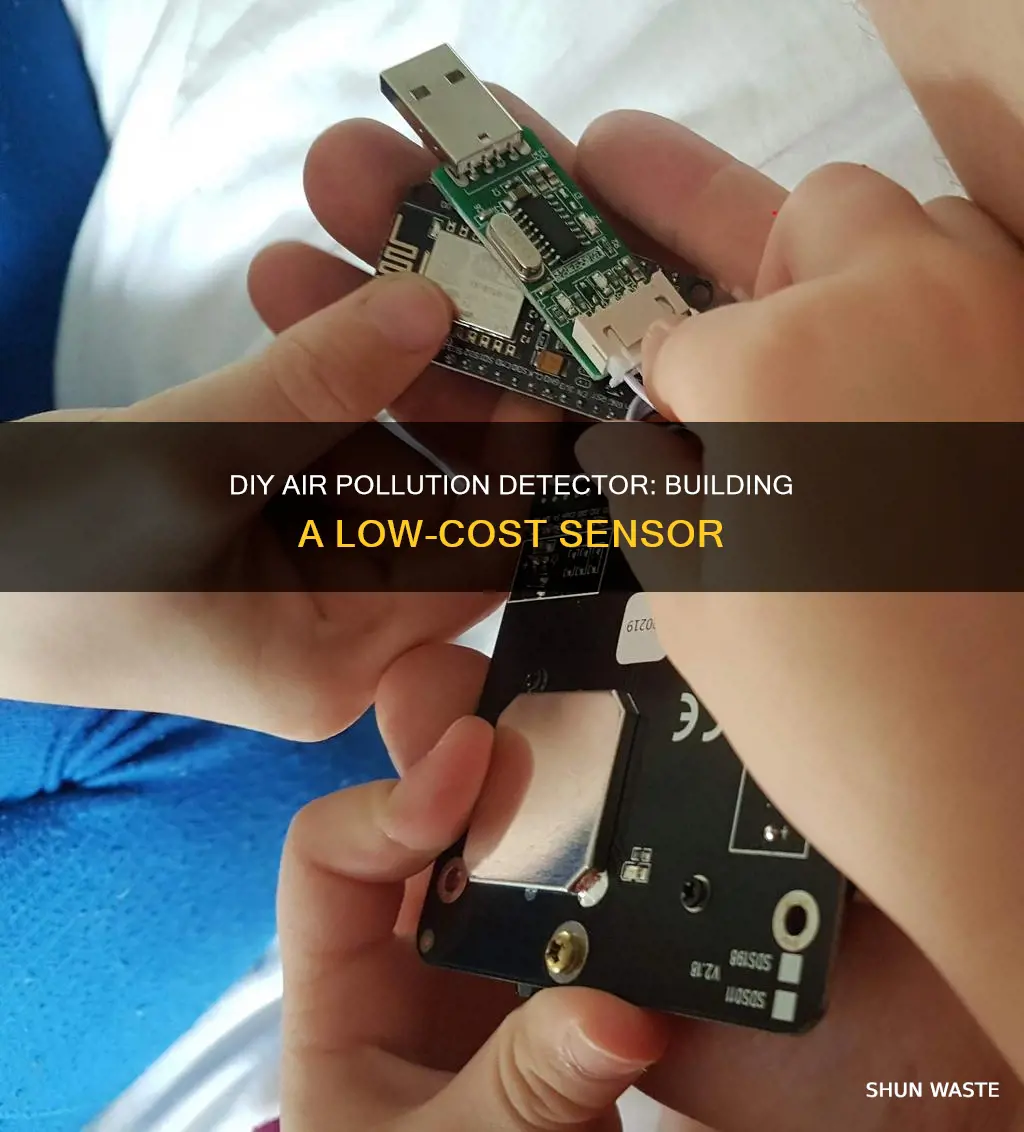

| Hardware | Intel Edison mounted on an Arduino Breakout board |

| Gas sensor | MQ-2; detects LPG, i-butane, methane, alcohol, hydrogen, smoke, etc. |

| Sensitivity | R in air/Rin typical gas >=5 Sensitive |

| Voltage | 3.3 - 5 volts |

| Display | LCD |

| Wearability | Can be attached to clothing or worn as a standalone patch (necklace or bracelet) |

Laser scattering

To achieve this, a constant flow fan blows fine particles or dust into the laser beam inside the sensor. Photodetectors are placed at specific positions to receive the scattered light and generate an electrical signal through the photoelectric effect. The circuit then amplifies this signal, providing data on the concentration of fine particles. This method is particularly useful for detecting particles with an aerodynamic diameter greater than 1 micrometre.

Additionally, laser scattering has been used in Lidar (laser radar) techniques to remotely observe atmospheric particulates, providing valuable data for air pollution monitoring. The development of high-power tunable lasers has made laser detection of pollution an attractive option for practical applications. For instance, spectroscopic analysis is a technique that uses lasers to identify and quantify specific gaseous constituents in the atmosphere.

Air Pollutants: Understanding the Different Types of Contaminants

You may want to see also

Gas-sensitive resistors

For example, the MQ-2 and MQ-9 gas sensors use gas-sensitive resistors (SnO2) to detect toxic gases like propane, butane, LPG, and carbon monoxide. These sensors are similar to the MiCS detectors, which use surface-mount sensors MiCS-2614 and MiCS-2714 to detect ozone and nitrogen dioxide, respectively. The sensing resistor is connected between the pins (G) and (K) on the circuit board, with a resistance of around 10-20 kΩ.

Another example is the Grove - HCHO Sensor, which is a semiconductor VOC gas sensor. It uses the VOC sensor WSP2110, which changes conductivity with the concentration of VOC gases in the air. This sensor can detect gases like toluene, methanal, benzene, alcohol, and acetone, and has a very high sensitivity and stability, being able to detect gas concentrations of up to 1ppm.

When building an air pollution detector using gas-sensitive resistors, it is important to calibrate the sensors with known concentrations of target gases to ensure accuracy. Additionally, the correct resistor values must be used, such as R1 = 1K, R2 = 2K, R6=100K or 1M, and R7=1K. The resistors are typically soldered to the circuit board, along with other components like transistors and capacitors, to create a functional air pollution detector.

Burning Cardboard: Polluting the Air?

You may want to see also

Calibration

Step 1: Understanding Calibration Techniques

There are two main types of calibration techniques for air pollution detectors:

- Calibration with Known Concentrations: This method involves exposing the sensor to known concentrations of target gases or pollutants. By comparing the sensor's response to these known concentrations, you can adjust and calibrate the device accordingly. This technique is commonly used with inexpensive sensors that vary significantly from component to component.

- Calibration through Co-location: This technique utilizes a reference station or instrument to provide data for comparison. By co-locating your air pollution detector with a reference instrument, you can calibrate it against the data provided by the reference source. This method is useful when dealing with complex or proprietary sensors.

Step 2: Selecting the Right Calibration Tools

Choose the appropriate calibration tools and equipment based on the type of air pollution detector you are using. For example, if you are working with gas sensors, you might need a certified calibration gas cylinder (ISO 6141, NIST) connected through a gashood. Ensure that you follow the manufacturer's guidelines or instructions for specific tool requirements.

Step 3: Preparing the Calibration Environment

Create a controlled environment to perform the calibration. This environment should simulate the conditions in which the air pollution detector will be deployed. Consider factors such as temperature, humidity, and pressure, as these variables can interfere with sensor measurements. Try to minimize any external factors that may impact the calibration process.

Step 4: Collecting Baseline Data

Before calibrating, collect baseline data by placing the detector in the controlled environment without any pollutants or gases present. This step helps establish a reference point for the calibration process. Record the sensor's response, including any initial readings or outputs.

Step 5: Introducing Known Concentrations

Gradually introduce known concentrations of target gases or pollutants into the controlled environment. Start with lower concentrations and gradually increase them to cover the full range of detection for your device. Record the sensor's response at each concentration level, including voltage outputs, resistance values, or any other relevant measurements.

Step 6: Adjusting and Refining

Compare the sensor's response to the known concentrations introduced. Adjust the sensor measurements accordingly to match the reference values. This step may involve altering sensitivity settings, applying calibration factors, or using specialized software to refine the sensor performance. Refer to the manufacturer's instructions or seek technical support for specific adjustment procedures.

Step 7: Validation and Testing

After calibration, validate the accuracy of your air pollution detector by conducting tests in controlled environments with known pollutant concentrations. Compare the sensor's readings against the known values to ensure that the calibration was successful. Repeat the calibration process if discrepancies or inaccuracies are observed.

Additional Considerations:

- Regular Calibration: Sensors may require periodic calibration to maintain accuracy. Fluctuations in temperature, humidity, and other environmental factors can impact sensor performance over time.

- Factory Calibration: Some sensors, such as the Kunak AIR stations, come with factory calibration. These sensors are pre-calibrated and certified, eliminating the need for initial calibration. However, periodic calibration may still be necessary due to sensor drift or changing environmental conditions.

- Data Interpretation: After collecting data from your air pollution detector, refer to government standards and guidelines, such as the US EPA Technical Assistance Document, to interpret the data accurately.

Dubai's Air Pollution: A Serious Concern?

You may want to see also

Circuitry

The circuitry of an air pollution detector is a crucial component that enables the device to accurately measure and interpret air quality data. Here is a detailed explanation of the circuitry involved in assembling an air pollution detector:

The detector typically uses an infrared LED and a photodetector or a photodiode to measure the scattering of light off small airborne particulates. The infrared LED emits a focused beam of light, which interacts with the particles in the air. The photodetector then captures the scattered light, and internal circuitry converts this light data into digital output signals. The low-pulse occupancy percentage, which represents the fraction of time the output signal is low, is directly proportional to the concentration of particulate matter in the air.

For gas detection, MQ-2 and MQ-9 sensors, similar to MiCS detectors, are commonly employed. These sensors utilize a gas-sensitive resistor (SnO2) to detect toxic gases and maintain an optimal sensing temperature with an internal heating element. The circuitry for the MQ-9 sensor differs slightly from the MiCS sensors, as it uses a transistor instead of a resistor to regulate heater power. When connecting the MQ-2 sensor, pins marked A should be connected to 5V power, pin G to ground, and pin S to ground in series with a 47 kΩ resistor. As for the MQ-9 sensor, pin A connects to the transistor, pin B to 5V power, pin G to ground, and pin S to ground in series with a 10 kΩ resistor.

Additionally, the Shinyei PPD42 Dust Sensor is another popular choice for collecting data about particulate matter. This sensor has two signal outputs: one for small particulate matter and the other for larger particulate matter. The detector requires a power supply of +5V and ground to function properly. The overall circuit diagram will provide a comprehensive understanding of the connections between the sensors and the Arduino board.

It is important to note that the circuitry and calibration of the air pollution detector are intricate processes. Referring to detailed guides, diagrams, and instructions is essential to ensure the accuracy and safety of the device.

Air Pollution: A Cause for Nosebleeds?

You may want to see also

Sensor types

The type of sensor you choose for your air pollution detector will depend on the type of air pollution you want to detect. Here are some of the most common types of sensors used in air pollution detectors:

- Gas Sensors: Gas sensors are used to detect the presence of harmful gases in the air, such as LPG, i-butane, methane, alcohol, hydrogen, smoke, ozone, carbon monoxide, sulfur dioxide, and nitrogen dioxide. The MQ-2 gas sensor, for example, has an operation voltage of 3.3 - 5 volts and is sensitive to a range of gases. Gas sensors typically use a combination of infrared LEDs and photodetectors to measure scattering off of small airborne particulates, with the photodetector output converted into digital output signals.

- Dust Sensors: Dust sensors measure the density of dust particles in the air. One example is the Shinyei PPD42 dust sensor, which outputs a low-voltage pulse when it detects particles. The fraction of time that the output signal is low, or the "low-pulse occupancy percentage," is proportional to the concentration of particulate matter in the air.

- Particulate Matter Sensors: These sensors focus on detecting and measuring particulate matter, which includes a range of airborne particles such as dust, pollen, and smoke. They may use lasers to measure the cloudiness of the air, similar to how dust particles can be seen indoors in sunlight.

- Town Gas Sensors: Town gas sensors are used to detect gas leaks or the presence of flammable gases.

- Temperature and Humidity Sensors: These sensors are important because temperature and humidity can impact the performance of other sensors, particularly gas sensors.

It is important to note that sensors may require calibration against known pollution sources to ensure accuracy. Additionally, wearable sensors are also an option, allowing users to monitor their personal air quality and health.

US States With the Cleanest Air Revealed

You may want to see also

Frequently asked questions

An air pollution detector is a device that uses sensors to detect, monitor, and report specific air pollutants like particulate matter (PM) or carbon dioxide, as well as environmental factors such as temperature and humidity.

Building your own air pollution detector can be a cost-efficient way of determining air quality. It can also be a fun DIY project, allowing you to customise the device to your specific needs and gain a deeper understanding of your environment.

The sensors you use will depend on the specific pollutants you want to detect. For example, if you want to detect particulate matter, you can use a Shinyei PPD42 dust sensor or a laser scattering sensor. If you want to detect carbon dioxide, you can use an MH-Z19 sensor or a non-dispersive infrared sensor. For volatile organic compounds (VOCs), you can use an MP503 sensor, and for ozone, you can use an MQ131 sensor.

In addition to choosing the right sensors, you will need to consider the circuitry and calibration of your device. You will also need to design a case or enclosure for your device, which can be done using CAD software and materials such as transparent acrylic.