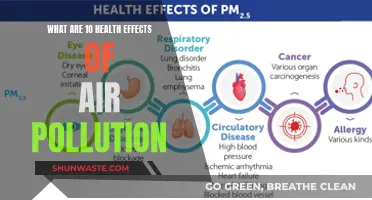

Air pollution from thermal power plants is a pressing issue, with plants contributing significantly to environmental pollution and emitting numerous hazardous pollutants. These pollutants, including mercury, arsenic, and nitrogen oxides, pose serious health risks, from acute breathing problems to cancer and even mental health issues. As a result, there is a critical need to control and reduce air pollution from these sources. This involves implementing technologies and standards to minimise emissions and their impact on human health and the environment. With global committees setting ambitious targets for emission reduction, the challenge is to adopt effective strategies to meet these goals and mitigate the adverse effects of thermal power plants on air quality.

| Characteristics | Values |

|---|---|

| Main sources of air pollution in thermal power plants | Mercury metal compounds, non-mercury metals, toxic gases, and particulate air contaminants |

| Harmful pollutants emitted from power plants | Arsenic, chromium, lead, formaldehyde, acid gases, dioxins, furans, soot, nitrogen oxides, sulfur dioxide, carbon dioxide, dust, heavy metals |

| Health risks | Cancer, eye, skin, and breathing passage damage, cardiovascular disease, kidney, lung, and nervous system damage, acute breathing difficulties, worsening of asthma, occupation-related cancers, damage to babies' and children's brains |

| Regulatory standards | Mercury and Air Toxic Standards (MATS), Clean Air Act, Minimum Achievable Control Technology (MACT) standard, Emission Collection and Monitoring Plan System (ECMPS) |

| Control methods | Use of less polluting fuel sources, more efficient combustion technologies, flue gas scrubbing, wet/dry/semi-wet flue gas pollution control processes, dust filtration or removal, injection of powdered activated carbon, Selective Non-Catalytic Reduction (SNCR), Selective Catalytic Reduction (SCR) |

| Challenges | Continuous improvement needed, difficulty in assessing emission rates of pollutants |

What You'll Learn

Mercury and Air Toxic Standards (MATS)

MATS specifically targets mercury emissions from coal and oil-fired power plants, which have been a significant source of air pollution. Mercury is a highly toxic neurotoxin that can cause irreversible damage to the human body, including blindness, deafness, and impaired coordination and speech. It is a potent chemical element that does not break down in the environment and can accumulate in the tissues of living organisms. As such, the regulation and reduction of mercury emissions are crucial to protecting public health.

The MATS rule was first introduced in 2011 by the Obama administration, aiming to limit emissions from over 580 coal and oil-fired power plants across the nation. These power plants were estimated to contribute significantly to mercury, acidic gas, and toxic metal emissions in the United States. The implementation of MATS was projected to bring about significant health benefits, including reducing premature deaths, heart attacks, and asthma attacks.

However, the journey towards establishing and upholding MATS has faced several challenges. Initially, the Bush administration did not set a MATS standard despite the EPA's determination in 2000 that regulating hazardous air pollutants was "appropriate and necessary". It wasn't until 2012 that the Obama administration took action and set the MATS rule, which took effect in 2015. The rule has since been challenged in court by states and industry groups, leading to ongoing legal battles and revisions to the standards.

Despite the challenges, the EPA has continued to defend and strengthen MATS. In 2023, the Biden administration reinstated and enhanced the MATS rule, particularly targeting power plants that burn lignite coal. Continuous emissions monitoring systems are now required at all coal power plants to ensure compliance with the standards. While progress has been made, there are still calls for further improvements to MATS to better protect public health and the environment from the devastating impacts of mercury and toxic air pollution.

What Are CFCs: Air Pollutants or Not?

You may want to see also

Using less polluting fuel sources

Fossil fuels are natural energy sources formed by the decomposition of organic matter buried deep within the Earth's crust over millions of years. They consist mainly of carbon-rich fuels such as coal, petroleum, and natural gas. Fossil fuels are used to generate electricity in thermal power plants, which burn these fuels to produce electricity.

Thermal power plants contribute significantly to greenhouse gas emissions, particularly nitrogen oxides, sulfur dioxide, carbon dioxide, dust, and heavy metals. To improve their environmental footprint, one of the three production stages that can be acted upon is the fuel source. Using less polluting and higher-quality fuel is essential to reducing emissions, except in the case of incinerators.

One alternative to fossil fuels is biomass, which is a renewable energy source derived from organic materials such as wood, crops, and waste residues. Biomass can be burned directly or converted into biofuels, providing a cleaner and more sustainable option for thermal power plants. Another option is natural gas, which is a fossil fuel but emits less pollution than coal when burned. Transitioning from coal to natural gas can significantly reduce nitrogen oxide and sulfur dioxide emissions, improving air quality.

Additionally, waste-to-energy technologies can be employed, where everyday waste is transformed into energy through incineration. While this approach may not reduce pollution, it can help manage waste disposal and divert waste from landfills, thereby reducing methane emissions.

By adopting less polluting fuel sources, thermal power plants can play a crucial role in reducing their environmental impact and contributing to global efforts to mitigate climate change.

Air Pollution: Understanding the Mechanics of Contaminated Air

You may want to see also

Flue gas depollution

One common method of flue gas depollution is the use of lime, which can absorb acid gases like fluorine, chlorine, and sulphur. As the lime dries, it turns into a dry powder, making it easy to eliminate these pollutants. This process is known as lime injection and can be done using milk of lime, which is a mixture of slaked lime and water. The milk of lime also increases the humidity rate of the fumes, reducing their temperature.

Another technique for flue gas depollution is the injection of urea directly into the flue gases to reduce NOx emissions. Urea is an ammonia derivative that can be easily manufactured industrially. This process, known as Selective Non-Catalytic Reduction (SNCR), is widely used in cement factories and incineration plants due to its simplicity. It involves spraying urea into the fumes at 900°C, achieving a 40-60% reduction in NOx. Alternatively, Selective Catalytic Reduction (SCR) is used in power plants, employing low-temperature heterogeneous catalysis to achieve up to 95% DeNox efficiency.

Additionally, flue gas treatment technologies have been developed to remove specific pollutants. For example, electrostatic precipitators and fabric filters can remove elemental and oxidized mercury from flue gases, with wet scrubbers being particularly effective for oxidized mercury. Dry scrubbers, when combined with a baghouse (a dust collection system), can remove up to 90% of mercury. While technologies for mercury and carbon dioxide removal have historically lagged, there is growing interest in improving these areas.

Overall, flue gas depollution is a critical aspect of reducing emissions from thermal power plants. By employing various technologies and techniques, such as lime injection, urea injection, and specialised flue gas treatment processes, operators can effectively reduce the release of harmful pollutants into the environment.

Improving Hong Kong's Air Quality: Strategies for Change

You may want to see also

SCR (Selective Catalytic Reduction)

Selective Catalytic Reduction (SCR) is an important emissions control technology used in coal, biomass, waste-to-energy, and gas-fired power plants. SCR is a process that removes NOx from flue gas emitted by power plant boilers, gas turbines, and other combustion sources. NOx refers to nitric oxide (NO), nitrogen dioxide (NO2), and other oxides of nitrogen, which can cause severe respiratory problems and other adverse environmental effects when released into the atmosphere.

The SCR process involves injecting ammonia (NH3) or urea into the exhaust gas upstream of a catalyst. The ammonia or urea reacts with NOx and oxygen (O2) to form nitrogen (N2) and water (H2O). The catalyst's active surface is typically made from a noble metal, base metal (titanium or vanadium) oxide, or a zeolite-based material. The geometric configuration of the catalyst body is designed for maximum surface area and minimum obstruction of the flue gas flow path to maximize conversion efficiency.

SCR technology is temperature-dependent, and the catalytic reaction is optimized at a specific temperature. The temperature requirements can pose challenges for some coal and gas-fired power plants, as operating requirements have changed with the addition of wind and solar power to the grid. However, natural gas may be easier to work with due to the absence of sulfur and particulate matter in the gas stream.

SCR has been widely adopted in various industries, including power plants, chemical processing plants, refineries, and municipal waste plants. It was first applied in thermal power plants in Japan in the late 1970s and has since been introduced in other regions, such as Europe and the United States, to meet emissions regulations and limits.

How Wind Impacts Air Pollution: A Complex Relationship

You may want to see also

Monitoring air quality

One method for monitoring air quality is through the use of modelling and indices. For instance, Upadhyaya and Dashore (2011) developed a fuzzy model for monitoring the Air Quality Index, which provides a comprehensive indicator of overall air quality. This model can be used to assess the impact of thermal power plants on air pollution by taking into account various parameters, such as pollutant concentrations and weather conditions.

Another approach to monitoring air quality is through the use of measurements and data collection. This involves deploying sensors and equipment to measure the concentrations of specific pollutants in the air, such as SO2, O3, NO2, CO2, CO, and CH4. These measurements can be taken at multiple locations around the thermal power plant, including at the plant's stack, property boundaries, and nearby communities. By continuously monitoring these pollutant levels, power plant operators can identify any exceedances of regulatory limits and take corrective actions to reduce emissions.

Satellite technology and ground-based measurements can also be combined to assess the impact of thermal power plants on air quality. This approach was used to study the Bandar Abbas thermal power plant in Iran, where satellite images and ground data were used to determine the Sea Surface Temperature, Total Organic Carbon, and Chemical Oxygen Demand as biological indices of environmental impact. Additionally, atmospheric measurements of pollutants were taken to understand the plant's contribution to air pollution.

To facilitate the reporting of air pollution data, regulatory agencies like the U.S. Environmental Protection Agency (EPA) have developed electronic tools. The EPA's Emission Collection and Monitoring Plan System (ECMPS) allows power plant operators to submit reports on their MATS (Mercury and Air Toxics Standards) progress conveniently. This system enables regulators to track power plant compliance with air pollution standards and ensure that appropriate controls are in place to reduce harmful emissions.

Air Pollution: 6 Common Questions Answered

You may want to see also

Frequently asked questions

The main sources of air pollution in thermal power plants are nitrogen oxides, sulfur dioxide, carbon dioxide, dust, heavy metals, and particulate carbon (soot).

Air pollution from thermal power plants poses significant health risks, including acute breathing difficulties, asthma, cancer, cardiovascular disease, and damage to the eyes, skin, kidneys, lungs, and nervous system. Mercury, a potent neurotoxin, can cause permanent brain damage in babies and children, leading to developmental delays and learning disabilities.

The U.S. Environmental Protection Agency (EPA) adopted the Mercury and Air Toxics Standards (MATS) in 2011, which aim to regulate emissions from all power plants. The Minimum Achievable Control Technology (MACT) standard is also used to set emission control standards. Globally, committees are setting targets for reducing emissions, with Europe implementing strict directives.

Technologies such as Selective Non-Catalytic Reduction (SNCR) and Selective Catalytic Reduction (SCR) are employed to reduce nitrogen oxide emissions. SCR is used in power plants for electricity production and involves a complex honeycomb system. Injection of powdered activated carbon is another method to reduce emissions by increasing pollutant absorption.

By using less polluting and higher-quality fuel sources, emissions can be reduced. Implementing more efficient combustion technologies can also minimize emissions during the combustion stage. Flue gas depollution techniques, such as using lime to absorb acid gases, are effective in reducing pollutants.