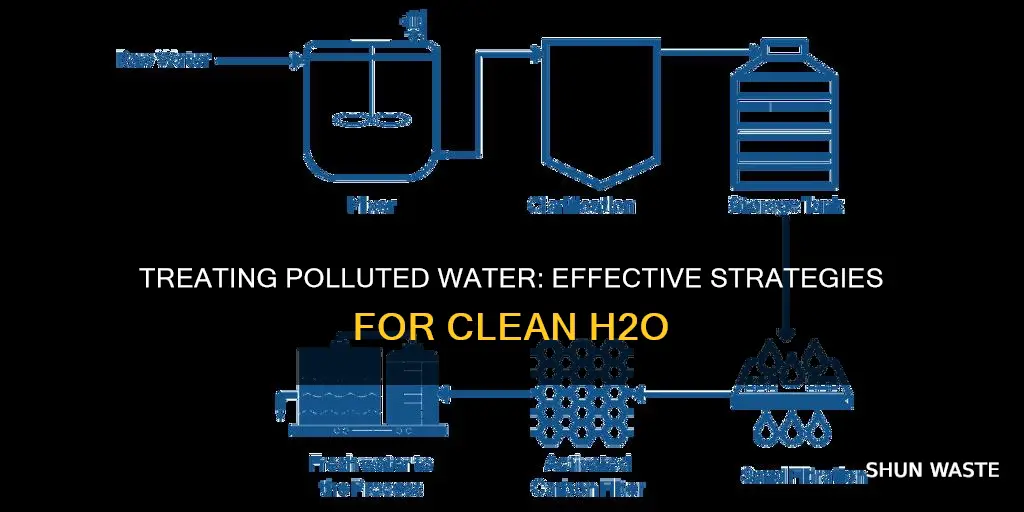

Water pollution is a pressing issue that has detrimental effects on both the environment and human health. It is caused by the introduction of various contaminants into water bodies, including sewage discharges, industrial and agricultural activities, and urban runoff. To combat this issue, wastewater treatment methods are employed to remove or reduce the concentration of impurities, making the water suitable for specific purposes such as drinking, irrigation, or recreational activities. The treatment process involves multiple stages, including primary, secondary, and advanced treatments, utilizing physical, biological, and chemical processes to eliminate solids, organic matter, bacteria, and other pollutants. The success of wastewater treatment relies on proper infrastructure, management plans, and legislation, with the ultimate goal of protecting our environment and ensuring safe water usage.

Characteristics of Treating Polluted Water

| Characteristics | Values |

|---|---|

| Water Sources | River, Lake, Wells, Bottled Water |

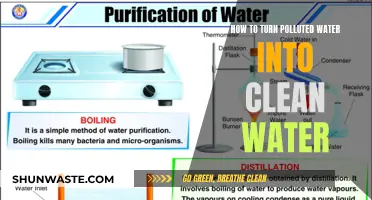

| Water Treatment Methods | Boiling, Filtering, Disinfection, Bleach, Iodine, Water Disinfection Tablets |

| Contaminants | Nutrients, Pathogens, Bacteria, Viruses, Fertilizers, Pesticides, Metals, Solvents, Grease, Oil, Chemical, Sewage, Sludge, Arsenic, Fluoride, Lead |

| Water-related Diseases | Diarrhea, Cholera, Giardia, Typhoid, Legionnaires' disease, Dengue Fever, Schistosomiasis |

| Water Pollution Causes | Farms, Industrial Wastewater, Sewage Treatment Facilities, Natural Disasters, Fossil Fuels, Septic Systems, Chemical Spills, Illegal Dumping |

| Prevention | Understanding Water Sources, Treating Wastewater, Managing Urban, Industrial, and Agricultural Wastewater, Watershed Restoration, EPA Standards and Regulations |

| Challenges | Inadequate Infrastructure, Climate Change, Water Scarcity, Population Growth, Demographic Changes, Urbanization, Lead in Drinking Water |

What You'll Learn

Sewage treatment plants

The construction of centralised sewage treatment plants began in the late 19th and early 20th centuries, primarily in the United Kingdom and the United States. The main idea behind these plants was to treat sewage before discharging it into bodies of water, as simply diluting sewage in large bodies of water was insufficient for densely populated areas.

Wastewater treatment plants in the United States process approximately 34 billion gallons of wastewater every day. This wastewater comes from homes and businesses and contains various pollutants, including nitrogen and phosphorus from human waste, food, and certain soaps and detergents. It is important to treat these pollutants effectively, as they can have detrimental effects on the environment if released into local water bodies without proper treatment.

To ensure the efficient removal of pollutants, sewage treatment plants may employ optimisation techniques and technology upgrades. This includes strategies to reduce nitrogen and phosphorus loads, as well as pretreatment processes for industrial wastewater to prevent toxic chemicals from interfering with biological treatment processes. Proper maintenance of septic systems is also crucial to prevent the release of elevated levels of nitrogen and phosphorus into local water bodies or groundwater.

Water Pollution: Human Impact and Our Responsibility

You may want to see also

Septic tank systems

The treated liquid effluent is typically disposed of in a septic drain field, which provides further treatment. However, groundwater pollution can still occur. To prevent this, a code of practice has been developed by organizations like the Environmental Protection Agency to regulate the planning and construction of new septic tanks, secondary treatment systems, septic drain fields, and filter systems. For example, direct discharge of septic tank effluent into groundwater is prohibited in Ireland, while indirect discharge via unsaturated subsoil is permissible.

There are several types of septic systems, each with its own advantages and disadvantages. Sand filter systems, for instance, provide a high level of treatment for nutrients and are suitable for sites with high water tables or close proximity to water bodies. However, they are more expensive than conventional septic systems. Gravel/stone systems, on the other hand, are relatively large in overall footprint and may not be suitable for all residential sites or conditions.

Aerobic Treatment Units (ATUs) mimic the processes of a municipal sewage plant but on a smaller scale. They inject oxygen into the treatment tank, increasing natural bacterial activity and providing additional treatment for nutrients in the effluent. Some ATUs also have pretreatment and final treatment tanks, including disinfection, to further reduce pathogen levels.

Constructed wetlands are another type of septic system that mimics the treatment processes of natural wetlands. Wastewater flows from the septic tank and enters a wetland cell, where it is treated by microbes, plants, and other media that remove pathogens and nutrients. This system can work via gravity flow or pressure distribution.

To maintain a healthy septic system, regular maintenance and the use of septic tank treatment liquids or additives are important. These liquids contain billions of enzyme-producing bacteria that break down organic solids, prevent clogs, eliminate odors, and reduce the time between septic tank pump-outs.

Water Quality: Pollution's Impact and Our Future

You may want to see also

Ozone treatment

Ozone water treatment, also known as ozonation, is an alternative sanitizing technology to common conventional disinfectants. It is a powerful disinfectant and has been used commercially as a water treatment system since 1904. Ozone is a strong oxidizing agent, capable of killing bacteria and viruses in water, and is particularly effective in treating wastewater and sewage systems that contain carbon-based and organic chemicals, as well as other water pollutants.

Ozone is a more effective disinfectant than chlorine, as it can eliminate germs, chlorine, iron, and bacteria, as well as improve the colour, taste, and odour of water. It is also 12 times more soluble in water than chlorine, allowing for a quicker disinfection process.

However, there are some disadvantages to using ozone. Firstly, it is a highly reactive and toxic substance, and can form carcinogenic by-products. It also has a high cost and requires significant maintenance. Additionally, ozone breaks down rapidly, especially at higher temperatures or in alkaline (high pH) conditions, which can make it difficult to control.

To use ozone effectively, it is important to understand its properties and potential drawbacks. When using ozone to disinfect water, it is crucial to ensure a high enough concentration to eliminate all germs and bacteria. The ozone dosage can be adjusted by changing the distance between the ozonisation equipment and the water surface, as well as the treatment duration and temperature.

Water Pollution: Destroying Nature's Balance

You may want to see also

Chlorination

Chlorine is added to raw water to eliminate algae and other forms of aquatic life, preventing problems in the later stages of water treatment. It also helps to control biological growth, remove iron and manganese, improve taste and odour, and remove colour from the water. Chlorine inactivates microorganisms by damaging their cell membranes, disrupting cell respiration and DNA activity, which are necessary for their survival.

The U.S. Environmental Protection Agency (EPA) regulates the amount of chlorine in drinking water to ensure it is safe for human consumption. While the levels used for disinfection are unlikely to cause long-term health effects, during water treatment, chlorine can combine with organic matter to form disinfection byproducts (DBPs), which can have negative health effects after regular, long-term exposure. Therefore, public water systems that use chlorination must regularly test their treated water to ensure DBP levels are within acceptable limits.

Rainwater's Pollution: Nature's Tears or Our Future?

You may want to see also

Constructed wetlands technology

Constructed wetlands are a low-cost, low-maintenance, ecologically sustainable, and robust technology for treating polluted water. They are designed to replicate the functions of natural wetlands, which have been used informally for wastewater treatment for hundreds of years.

Constructed wetlands use natural processes involving wetland vegetation, soils, and their associated microbial assemblages to improve water quality and remove contaminants from discharge. They are particularly effective for treating industrial wastewater, municipal wastewater, stormwater, and agricultural wastewater.

There are two main types of constructed wetlands: subsurface flow and surface flow. Both are constructed on top of an impermeable basin that is placed in the ground. Subsurface flow wetlands purify water under the surface of the soil and are filled with porous soils and sand. Water is purified vertically through the soil and collected in pipes in the underlying basin, or it can move diagonally through the soil layer.

The design and planning process for constructed wetlands is complex and requires an interdisciplinary team of experts in various fields, including chemistry, hydrology, soil science, plant biology, and environmental engineering. The sizing and placement of specific systems within the treatment chain are determined by the chemical and physical characteristics of the principal contaminants that need to be removed.

Constructed wetlands offer multiple benefits, including improved water security and access, climate change adaptation, biodiversity, and reduced water treatment costs. They also create green spaces that provide habitats for wildlife and can enhance the recreational, educational, and aesthetic value for local communities.

Air and Water Pollution: Government Regulation and Control

You may want to see also