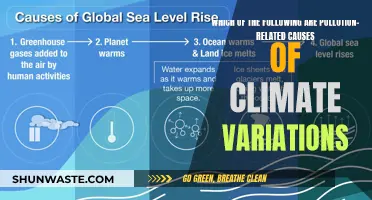

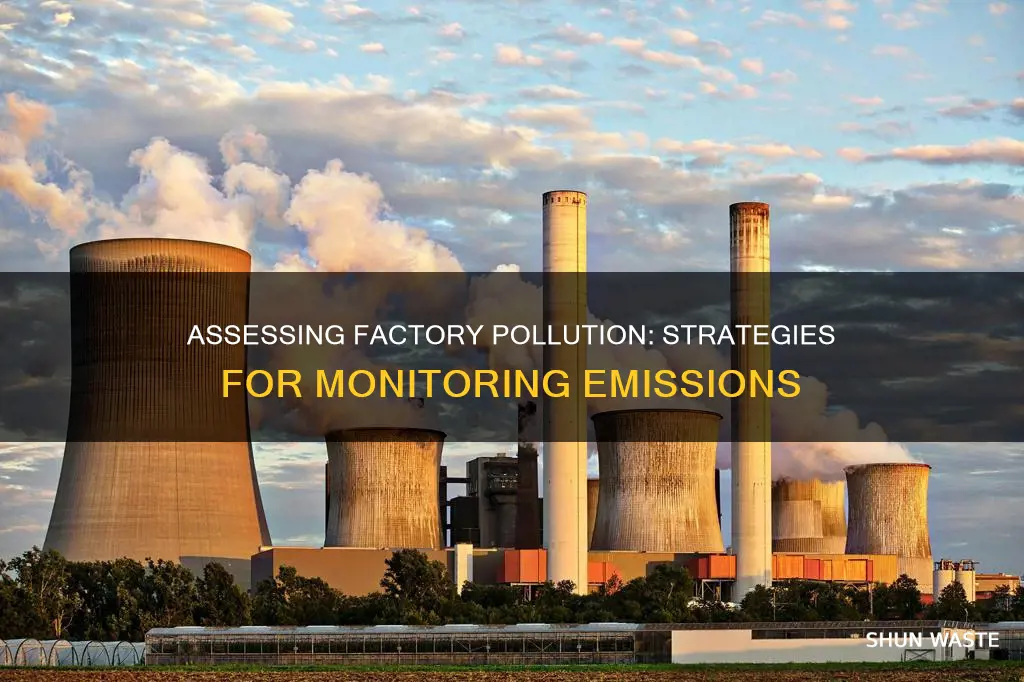

Factory pollution is a leading global environmental problem, contributing to air, water, and soil pollution, as well as waste generation and resource consumption. Factories emit carbon dioxide, carbon monoxide, carbon tetrachloride, and other harmful pollutants that can cause serious illnesses and contribute to climate change. To check and reduce factory pollution, it is crucial to analyze waste output, implement waste treatment processes, consider the location and impact of industrial sites, and enforce regulations with governmental oversight. Smart technology and data analytics also play a key role in monitoring and combating pollution.

| Characteristics | Values |

|---|---|

| Carbon-based pollutants | Carbon dioxide, carbon monoxide, carbon tetrachloride |

| Impact of carbon-based pollutants | Harm to the environment and human health |

| Air pollution sources | Factories, cars, trucks, and other vehicles |

| Air pollution prevention | Carpooling, using renewable energy sources, reducing carbon footprint |

| Water pollution sources | Dumping of chemicals or hazardous waste, industrial releases |

| Water pollution prevention | Environmental governance initiatives, regulations, enforcement of environmental legislation |

| Soil pollution sources | Soil toxicity, agricultural inputs |

| Soil pollution prevention | LCA methods, pollution prevention strategies |

| Impact of factory pollution | Health problems (e.g. irritation, headaches, asthma, increased risk of cancer), environmental damage |

| Pollution control | Laws and regulations, local/state/federal agencies, monitoring systems |

What You'll Learn

- Pollution certificates: Governments issue these to industries to certify they meet national standards for controlling pollution

- Location: Factories should be built away from ecologically sensitive areas, and climate/topography should be considered to reduce the spread of pollutants

- Energy sources: Using renewable energy sources to power factories reduces pollution and saves money in the long run

- Waste treatment: Treating waste through physical, chemical, or biological processes before disposal reduces its volume and toxicity

- Government regulations: Stringent environmental regulations, levies, and cap-and-trade systems can help decrease factory pollution

Pollution certificates: Governments issue these to industries to certify they meet national standards for controlling pollution

Governments issue pollution certificates to industries to certify that they meet national standards for controlling pollution. These certificates are a type of official document that verifies a factory complies with regulatory limits on emissions and waste management. They are typically linked to the type of industry and the scale of its operations. For example, in India, Micro, Small, and Medium Enterprises (MSMEs) may require a pollution certificate if their activities have the potential to generate pollution, such as manufacturing or chemical production.

To obtain a pollution certificate, businesses must first identify the specific pollution control requirements for their industry and location. This often involves checking with the local Pollution Control Board (PCB) for guidelines and registering on their official website. The application process usually requires a range of documents, including the factory layout, production process details, waste management plan, and environmental impact assessment. In some cases, businesses must also certify that they have a plan to reduce waste and submit reports on their efforts to minimise waste volume and toxicity.

The pollution certificate itself serves as verification that a factory's pollution levels are within permissible limits. It ensures that emissions from industrial operations meet the environmental standards set by regulatory authorities, thus minimising the harmful impact on air, water, and soil quality. This is particularly important for factories that discharge environmentally hazardous wastes, such as chemical wastes, smoke emissions, and medical wastes, which can have severe consequences for human health and the environment.

By issuing pollution certificates, governments can encourage industries to adopt more sustainable practices and reduce their environmental footprint. This helps to address the pressing issue of factory pollution, which is a leading contributor to air pollution and climate change worldwide.

Sound Pollution: Understanding Its Various Causes

You may want to see also

Location: Factories should be built away from ecologically sensitive areas, and climate/topography should be considered to reduce the spread of pollutants

Factories are a leading cause of pollution globally, and their emissions are polluting the air and causing problems with air quality worldwide. To check and control factory pollution, it is imperative to consider the location of these factories and maintain a safe distance from ecologically sensitive areas.

Ecologically Sensitive Zones (ESZ) are designated areas that aim to protect and conserve natural habitats for specific species, while also minimising the conflict between human activities and nature. These zones are typically established around natural parks and wildlife sanctuaries, creating a protective buffer to regulate and control potentially harmful activities. India, for instance, has over 600 ESZs declared across various states, including Uttar Pradesh, Haryana, and West Bengal. Within these zones, activities such as commercial wood usage, industrial operations, mining, and tourism are restricted. The discharge of solid or fluid waste, the production of hazardous substances, and any actions leading to pollution are also prohibited.

When deciding where to build factories, it is crucial to keep them away from these ecologically sensitive areas to prevent further environmental degradation. Additionally, the climate and topography of the region should be carefully considered to reduce the spread of pollutants. Topography plays a significant role in the distribution of air pollution. For instance, in low-lying areas like valleys, air pollutants tend to become trapped due to weaker winds, causing pollution levels to rise. This phenomenon is further influenced by temperature inversions, where a layer of warm air traps a layer of cooler air closer to the Earth's surface, disrupting the natural vertical mixing of air masses.

By understanding the intricate link between topography and air pollution, strategies can be developed to effectively control and mitigate the impact of pollution. This includes considering the wind direction and speed, as well as the potential for temperature inversions, when deciding on factory locations. Additionally, renewable energy sources and fuel economy standards can be promoted to reduce greenhouse gas emissions from factories, which contribute to global warming and climate change.

Air Pollution in China: Understanding the Complex Causes

You may want to see also

Energy sources: Using renewable energy sources to power factories reduces pollution and saves money in the long run

Factory pollution is a leading global environmental problem. Most air pollutants come from factories, and these pollutants lead to increased rates of asthma, allergies, and other respiratory issues. Factories also contribute to greenhouse gas emissions, with about 80% of total greenhouse gas emissions in America coming from power, coal, or industrial output.

To reduce factory pollution, we can use renewable energy sources to power factories. Renewable energy sources are naturally replenished and emit little to no greenhouse gases or pollutants into the air. Wind and solar energy, for example, require no water to operate and thus do not pollute water resources. In contrast, fossil fuels can have a significant impact on water resources, as coal mining and natural gas drilling can pollute sources of drinking water, and all thermal power plants consume water for cooling.

The use of renewable energy sources to power factories reduces pollution and saves money in the long run. Firstly, renewable energy sources reduce air pollution. For example, a study showed $2 billion in health benefits from wind power, with 29% and 32% of these health benefits connected to racial and ethnic minorities and low-income populations, respectively. In contrast, a study from Harvard estimated $74.6 billion in life cycle and public health costs associated with coal every year in the United States. Renewable energy sources also reduce water pollution, as they do not require water for cooling like many fossil fuel plants.

In addition to reducing pollution, renewable energy sources can also save money. While the upfront cost of investing in renewable energy can be high, the reduction of pollution and climate impacts alone could save the world up to $4.2 trillion per year by 2030. Renewable energy sources are also becoming increasingly inexpensive, and the International Energy Agency (IEA) states that cheap electricity from renewable sources could provide 65% of the world’s total electricity supply by 2030.

Overall, using renewable energy sources to power factories reduces pollution and saves money in the long run.

Solar Panels: Pollution Paradox and the Energy Transition

You may want to see also

Waste treatment: Treating waste through physical, chemical, or biological processes before disposal reduces its volume and toxicity

Factory pollution is a leading environmental concern, and it is imperative to address it to prevent further harm to the environment and human health. A significant aspect of factory pollution is the emission of harmful gases, such as carbon dioxide, carbon monoxide, and sulfur dioxide, which contribute to air pollution and climate change.

To mitigate the pollution caused by factories, it is essential to treat waste effectively before disposal. Waste treatment involves physical, chemical, or biological processes that reduce the volume and toxicity of waste. Here are some detailed examples of these processes:

Physical Treatment:

- Centrifugation: This process uses centrifugal force to separate different components of waste, allowing for the isolation of hazardous materials.

- Mechanical Collection: Collecting waste through mechanical means, such as using machinery to pick up and transport waste to designated areas.

- Coagulation: This process involves the addition of coagulants to waste to promote the aggregation of small particles into larger ones, making them easier to remove.

- Sedimentation: Allowing waste to settle in a sedimentation tank, causing solid particles to separate from liquids, facilitating their removal.

- Filtering: Using filters to separate solid particles from liquids or gases, ensuring that pollutants are captured before safe disposal.

Chemical Treatment:

- Acid and Base Treatment: Using acids or bases to alter the pH of waste, rendering it less hazardous. For example, lime (calcium oxide) can be used to treat acidic wastewaters.

- Oxidation and Reduction: Employing oxidizers or reducers to modify the oxidation state of pollutants, making them less harmful or easier to remove.

- Electrolytic Bath Purification: This technique uses electricity to remove impurities from metal finishing processes, achieving commercial success in the industry.

- Carbon Filtering: Carbon filters are used to isolate carbon compounds, effectively minimizing liquid, gaseous, and solid waste. They are commonly employed in industries to reduce their pollution footprint.

Biological Treatment:

- Vermifiltration: This process uses worms to reduce sludge waste and is considered one of the most important biofiltration mechanisms.

- Electrocoagulation-Biological Activated Carbon Filtering: This method combines electrocoagulation with biological activated carbon filtering to separate dyes from wastewater, specifically in the dye and textile industries.

How Pollution Turns Sunsets Orange

You may want to see also

Government regulations: Stringent environmental regulations, levies, and cap-and-trade systems can help decrease factory pollution

Government intervention is critical to reducing factory pollution. Here are several strategies that governments can employ:

Stringent Environmental Regulations

Governments can implement and enforce strict environmental regulations that all factories must abide by. These regulations can include mandatory waste reduction techniques, such as analyzing waste output and establishing recycling systems, to reduce the overall amount of waste generated. Factories can also be required to treat their waste before disposal, using physical, chemical, or biological methods to make it less harmful to the environment.

Levies

Governments can impose financial penalties on factories that emit pollutants or produce excessive waste. These levies serve as a disincentive for polluters, as they would have to pay a fixed amount for the pollution they cause. This approach not only provides an economic incentive to reduce pollution but also generates revenue that can be used for environmental restoration or protection initiatives.

Cap-and-Trade Systems

Cap-and-trade programs are market-based approaches where governments set a limit on the amount of pollution allowed and create a market for companies to buy and sell allowances. As the cap gets stricter over time, total pollution drops, and companies have a financial incentive to reduce emissions by cutting them in the most cost-effective ways. This system has been successfully implemented in California, contributing to a steady decline in the state's carbon dioxide pollution while also fostering economic growth.

Energy Consumption Regulations

Energy consumption is a significant contributor to factory pollution. Governments can encourage or mandate the use of renewable energy sources, such as solar or wind power, to reduce the environmental impact of factories. While the initial investment in greener energy sources may be high, it can lead to long-term cost savings and significantly reduce pollution levels.

Factory Site Planning and Impact Assessments

When approving new industrial sites, governments can enforce strict regulations that consider the potential impact on the surrounding environment. By evaluating factors such as climate and topography, governments can ensure that factory construction minimizes harm to important ecosystems. Additionally, regular environmental impact assessments can be mandated for existing factories to identify and address any negative consequences their operations may have on the natural ecosystem.

Oil Refineries: Pollution's Unseen Culprit?

You may want to see also

Frequently asked questions

There are a few ways to check and monitor pollution caused by factories. One way is to analyse the waste output of factories, which can include food waste, chemical waste, glass, paper, and other elements. Another way is to utilise smart technology, which can provide advanced analytics and insights about air quality in a given area. Governments can also check the European Industrial Emissions Portal, which offers detailed information on the largest industrial complexes in Europe, releases and transfers of regulated pollutants to air, water and soil, as well as waste transfers.

Factories emit a variety of pollutants, including carbon dioxide, carbon monoxide, carbon tetrachloride, benzene, formaldehyde, and sulfur dioxide, among others. These pollutants are released into the atmosphere and contribute to air pollution, which has severe consequences for human health and the environment.

Factory pollution has been linked to increased rates of asthma, allergies, and other respiratory issues. It is also a significant factor in climate change and has been associated with serious illnesses such as lung cancer, cardiac illnesses, and lung infections.

To reduce factory pollution, it is important to consider the location of industrial sites and their potential impact on the surrounding environment. Factories can also analyse their waste output and implement changes to make processes more efficient, such as upgrading equipment, reorganising inventory, and establishing recycling systems. Governments can enforce regulations and take action against industries that do not follow pollution protocols, while also rewarding companies that operate within guidelines.