Scrubbers are an effective tool in the fight against rising carbon emissions and the release of acidic chemicals into the atmosphere. They are filters that use a scrubbing fluid, absorbent material, and other methods to remove chemical and particulate contaminants from emissions, thereby lowering the amount of pollution released through manufacturing and the burning of fossil fuels. Wet scrubbers are the most common type of scrubber, and they use a scrubbing liquid to separate the contaminations from the mixture so that decontaminated gas can be released back into the atmosphere. They are highly effective, removing over 90% of flue gases emitted by a coal exhaust. They are also versatile, cost-effective, and low maintenance, making them a popular choice for industries to stay compliant with environmental laws.

| Characteristics | Values |

|---|---|

| How scrubbers work | Use liquid solvents to remove pollution from air or liquid |

| Type of liquid used | Water or water-based solvent |

| Pollutants scrubbers can remove | Organic and inorganic pollutants, including volatile organic compounds, particulate matter, hazardous air pollutants, carbon dioxide, and acid gases |

| Efficiency | Removal efficiency of over 90% |

| Advantages | Cost-effective, versatile, low maintenance, small operating costs, manageable option for companies to comply with environmental protection laws |

| Disadvantages | Susceptible to operating problems if pressure differential, liquid flow, and gas flow are not kept constant |

| Industries that use scrubbers | Electricity production, industry emissions, transportation, and diesel engines |

What You'll Learn

- Wet scrubbers remove chemical and particle waste from polluted gases

- Wet scrubbers are purifiers that use scrubbing liquid to separate contaminations from gases

- Wet scrubbers are more versatile and effective than dry scrubbers

- Wet scrubbers are used in most production and electricity generation plants

- Wet scrubbers are a cost-effective method for controlling emissions

Wet scrubbers remove chemical and particle waste from polluted gases

Wet scrubbers are an effective method for removing chemical and particle waste from polluted gases. They are purifiers that use a scrubbing liquid, usually water, to separate contaminations from gases. This allows the decontaminated gas to be released back into the atmosphere.

Wet scrubbers are highly effective, with most absorbers having removal efficiencies of over 90%. They are also versatile, able to remove a wide range of pollutants, including organic and inorganic pollutants, particulate matter, volatile organic compounds, hazardous air pollutants, and inorganic fumes, vapours, and gases. This versatility makes them ideal for treating vapours from industries that produce multiple types of contamination.

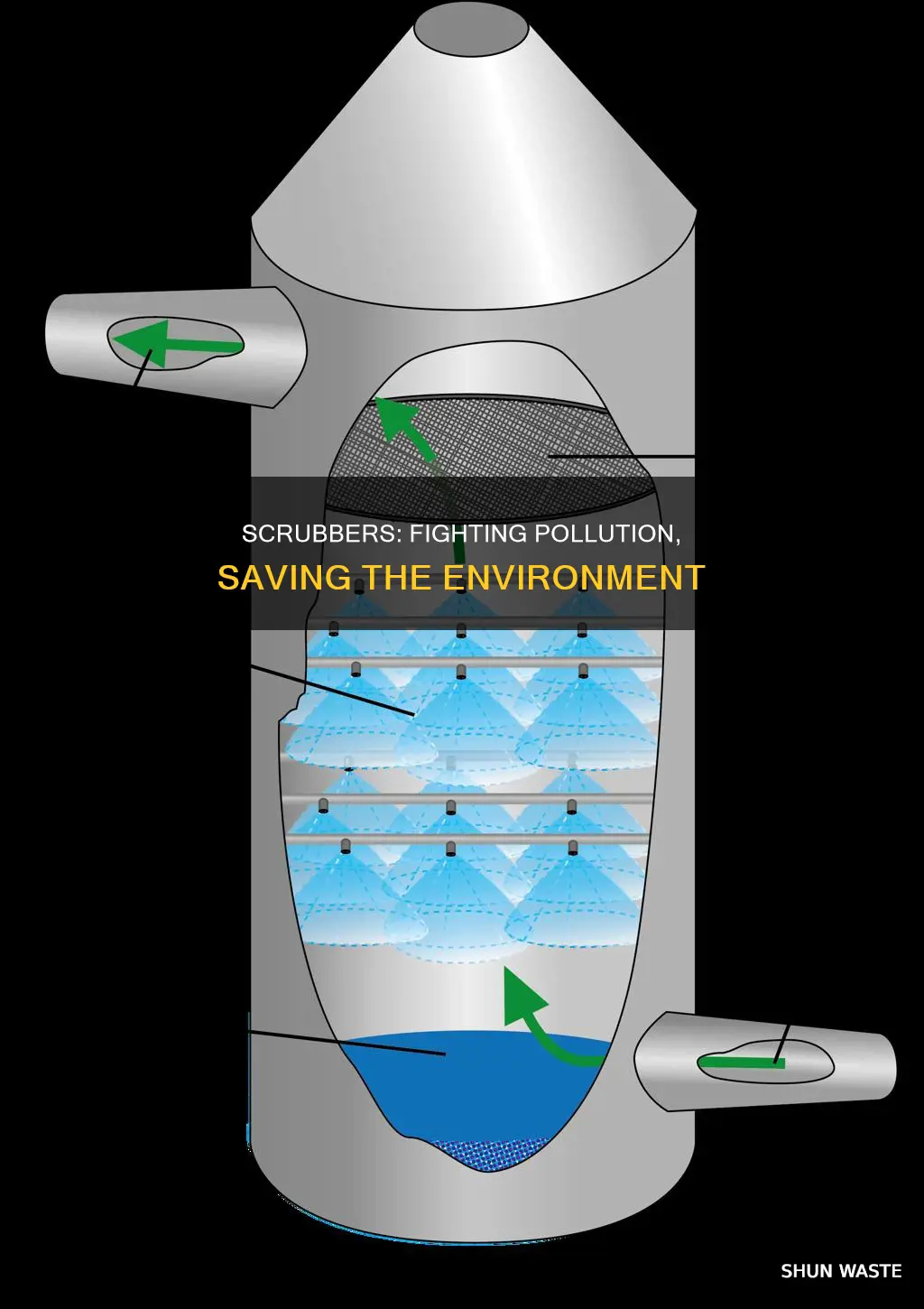

Wet scrubbers work by passing the contaminated gas through a packed bed and downward-flowing solvent sprays. The pollutants are collected in the solvent droplets, and the gas passes through a mist eliminator to capture any remaining droplets before being released. The large surface area of the packed bed allows for intimate contact between the liquid and gas stream, facilitating the absorption of pollutants.

The effectiveness of a wet scrubber depends on factors such as the solvent's composition, the liquid flow rate, and the target gas velocity. The solvent's electric charge is critical, as it determines which inorganic pollutants the solvent can bind with. The liquid flow rate, or the liquid-to-gas ratio, affects the volume of droplets available to capture pollutants. A higher liquid flow rate generally improves efficiency. The target gas velocity, or the speed of the contaminated gas, impacts the number of collisions and impaction events, which results in captured pollutants.

Wet scrubbers are commonly used in industries such as electricity production, industrial manufacturing, and wastewater treatment facilities, where they play a vital role in reducing air pollution and protecting human health and the environment.

Simple Ways to Reduce Air Pollution and Breathe Better

You may want to see also

Wet scrubbers are purifiers that use scrubbing liquid to separate contaminations from gases

Scrubbers are purifiers that remove chemical or particle waste from polluted gases. Wet scrubbers, the most common type of industrial purifier, use a scrubbing liquid to separate contaminations from gases.

Wet scrubbers are an effective technology for controlling harmful airborne pollutants and odours in process exhaust streams. They are industrial scrubbers that use water or other liquids to remove gas pollutants and odours from exhaust streams. Wet scrubbers are more effective than dry scrubbers in removing pollutants. They are also more versatile and cost-effective, eliminating more than 99% of airborne particulate matter.

Wet scrubbers work by absorbing pollutants with water or a water-based solvent. The contaminated gas enters at the bottom of the scrubber and passes upward through the packed bed and downward-flowing solvent sprays. The pollutants are collected in the solvent droplets, and the gas passes through a mist eliminator to capture any remaining droplets before being released.

Wet scrubbers can remove a wide range of different air pollutants, including inorganic fumes, vapours, and gases, volatile organic compounds, particulate matter, and hazardous air pollutants. They are necessary to minimise the environmental impact of industrial activities and to comply with governmental environmental protection laws.

Wet scrubbers have several advantages, including relatively low pressure drop, high mass-transfer efficiencies, adjustable packing height or type, low capital cost, small space requirements, and the ability to collect particulate matter and gases simultaneously. They are commonly used in most production and electricity generation plants, as well as in the transportation and diesel engine sectors.

Reducing Light Pollution: Strategies for a Brighter Tomorrow

You may want to see also

Wet scrubbers are more versatile and effective than dry scrubbers

Wet scrubbers are a highly versatile and cost-effective method of removing harmful pollutants from the air. They are particularly effective at removing acid gases and contaminants, and can eliminate over 99% of airborne particulate matter.

Wet scrubbers work by passing contaminated gas through a liquid, which absorbs the pollutants. The liquid used is usually water, but other liquids such as dimethylaniline or amines can be used for gases with low water solubility. The liquid is often charged, either positively or negatively, to ensure binding and removal of the contaminants.

Wet scrubbers are highly versatile as they can be used to remove a wide range of pollutants, including organic and inorganic compounds, hazardous air pollutants, particulate matter, and volatile organic compounds. They are also effective at removing pollutants from a variety of industries, including food and agriculture, chemical, aluminium, and steel mills.

Wet scrubbers are more effective than dry scrubbers as they can remove a wider range of pollutants and achieve a higher level of pollutant removal. Dry scrubbers, on the other hand, use a dry reaction material such as alkaline slurry to remove acids from gases. While dry scrubbers are more cost-effective and require less maintenance, they are not able to remove as many pollutants as wet scrubbers.

Wet scrubbers are an essential tool in the fight against air pollution and are highly effective at removing harmful contaminants from the air. Their versatility and effectiveness make them a popular choice for many industries looking to reduce their environmental impact.

Trees: Nature's Water Purifiers and Pollution Fighters

You may want to see also

Wet scrubbers are used in most production and electricity generation plants

Wet scrubbers are the most common type of industrial purifier. They are used to purify vapours and gases to acceptable levels before releasing them into the environment. They are highly effective at removing chemical and particle waste from polluted gases. Wet scrubbers use a scrubbing liquid, usually water, to separate contaminations from the mixture so that decontaminated gas can be released back into the atmosphere.

Wet scrubbers are also used to remove sulphur emissions from coal plants. They are large towers in which aqueous mixtures of lime or limestone are sprayed through the emissions exiting a coal boiler. The lime or limestone absorbs some of the sulphur from the flue gas, reducing the formation of acid rain.

Wet scrubbers are highly versatile and can be built in numerous configurations. They can be designed to collect particulate matter and/or gaseous pollutants. They can achieve high removal efficiencies for either particles or gases, and in some cases, they can achieve a high removal efficiency for both pollutants in the same system.

Wet scrubbers are often the only single air pollution control device that can remove both particulate matter and gases. They are particularly effective at removing inorganic fumes, gases, and odours. They can also remove volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

Wet scrubbers are a cost-effective method for controlling emissions and complying with governmental environmental protection laws. They have relatively low maintenance and operating costs compared to other pollution-minimizing solutions. They also have small space requirements, making them a manageable option for most companies.

Reducing Plastic Pollution: Practical Steps for a Greener Tomorrow

You may want to see also

Wet scrubbers are a cost-effective method for controlling emissions

Wet scrubbers are an effective method for controlling emissions and reducing air pollution. They are commonly used in industrial settings to remove chemical and particle contaminants from emissions, lowering the amount of pollution released into the atmosphere. Wet scrubbers use a scrubbing liquid, usually water, to absorb and separate contaminants from the gas stream, allowing decontaminated gas to be released back into the environment.

Wet scrubbers offer a contained and efficient solution for eliminating unwanted air contaminants. They can remove a wide range of pollutants, including organic and inorganic compounds, particulate matter, hazardous air pollutants, and volatile organic compounds. The versatility of wet scrubbers makes them suitable for various industries, including electricity production, industry emissions, and transportation.

One of the key advantages of wet scrubbers is their cost-effectiveness. They have relatively low capital costs for initial setup and lifetime maintenance. The operating costs of wet scrubbers are also relatively small, making them a manageable option for companies to comply with governmental environmental protection laws. The use of wet scrubbers can help companies avoid the costly fines and penalties associated with violating environmental regulations, such as the U.S. Clean Air Act (CAA).

Wet scrubbers are designed to maximize efficiency while minimizing energy consumption. They utilize large surface areas and specific flow patterns to facilitate intimate contact between the liquid and gas streams, optimizing the absorption process. Additionally, wet scrubbers have low pressure drops, which help to reduce energy usage and improve purification efficiency.

The design of wet scrubbers can vary depending on the specific application and the type of contaminants being targeted. Different scrubbing liquids and packing materials can be used to optimize the removal of particular pollutants. Wet scrubbers are also available in vertical and horizontal configurations, allowing for flexibility in terms of space requirements and filtration specialization.

Overall, wet scrubbers are a cost-effective and efficient solution for controlling emissions and reducing pollution. Their versatility, effectiveness, and relatively low operating costs make them a popular choice for industries aiming to comply with environmental regulations and reduce their environmental impact.

Cars: Reducing Pollution, Saving the Planet

You may want to see also

Frequently asked questions

Scrubbers are purifiers that remove chemical or particle waste from polluted gases. Wet scrubbers are the most common type of industrial purifier and they use a scrubbing liquid to separate the contaminations from the mixture so that decontaminated gas can be released back into the atmosphere.

Wet scrubbers use a liquid solvent to remove pollution from air or liquid. The contaminated gas enters at the bottom of the scrubber and passes upward through a packed bed and downward-flowing solvent sprays. The pollutants are collected in the solvent droplets, and before the gas leaves the scrubber, it passes through a mist eliminator to capture any droplets.

Wet scrubbers can remove organic and inorganic pollutants, including those that cause illness, deplete the ozone or disrupt ecosystems. They can also remove volatile organic compounds, particulate matter, hazardous air pollutants, and flue gases.

Scrubbers are versatile and effective, with a high rate of success in filtering multiple types of pollutants. They are also typically low maintenance and have relatively small operating costs, making them a cost-effective and manageable option for companies to comply with governmental environmental protection laws.

Wet scrubbers are used in most production and electricity generation plants as this is where the majority of air contamination comes from. They can also be used to reduce carbon emissions from compression-based engines, such as those found in diesel vehicles.