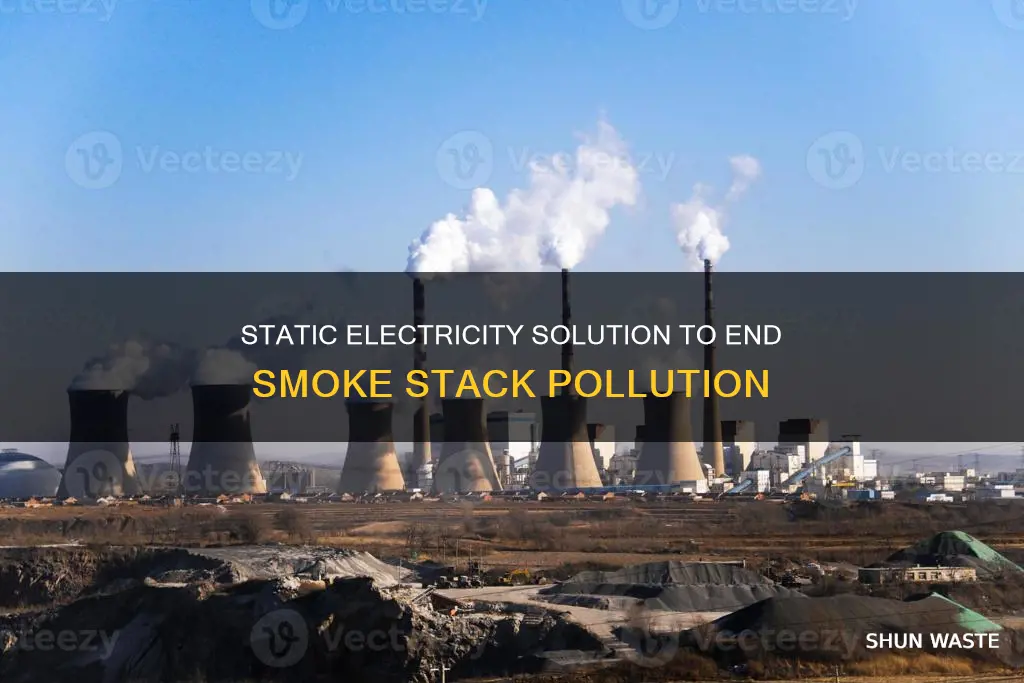

Static electricity can be harnessed to combat smoke stack pollution through the use of electrostatic precipitators, also known as scrubbers. These devices utilise static electricity to attract and capture soot and ash particles from dirty air emitted by smokestacks, significantly reducing pollution. The basic principle involves applying a static charge to the smoke particles, causing them to cling to oppositely charged collection plates or electrodes, thereby preventing them from escaping into the atmosphere. This technology has been effectively employed in industrial settings for over a century, playing a crucial role in mitigating pollution from factories and power plants.

| Characteristics | Values |

|---|---|

| Name of technology | Electrostatic smoke precipitators (ESP) |

| Other names | Scrubbers |

| How it works | Smoke is forced past two electrodes (metal wires, bars or plates) inside a pipe or smokestack. The first electrode is charged to a very high negative voltage, causing the dirt particles to pick up a negative charge. The second electrode is charged to a high positive voltage, attracting the negatively charged soot particles and causing them to stick to it. |

| Effectiveness | State-of-the-art precipitators remove over 99% of particulates in flue gas moving at typical speeds of 20cm per second. |

| Limitations | ESPs are not suitable for residential use due to the risk of ozone production, which is harmful to human health. They are also less effective with low-sulfur coal, which produces more ash and requires more energy to trap smoke. |

What You'll Learn

- Electrostatic smoke precipitators, or scrubbers, use static electricity to remove soot from smoke

- Smoke is given an electric charge and passes by electrodes of the opposite charge, causing the particles to cling to them

- Electrostatic precipitators are designed differently for varying amounts of pollution and types of dirt particles

- The effectiveness of electrostatic precipitators is impacted by the temperature and moisture content of the flue gas

- Electrostatic precipitators are not suitable for residential use due to the risk of ozone production

Electrostatic smoke precipitators, or scrubbers, use static electricity to remove soot from smoke

Electrostatic smoke precipitators, also known as scrubbers, are an effective way to remove soot from smoke. They use static electricity to attract and capture the microscopic particles of soot, which are unburned carbon, that are dispersed in hot, rising air.

The basic principle behind electrostatic smoke precipitators is similar to the static electricity experiment where you rub a balloon on a sweater to generate an electric charge that makes the two objects stick together. In the case of smoke, it is made up of tiny particles of soot suspended in a gas. By applying an electric charge to these particles, they can be attracted to and collected on a plate with the opposite electric charge, effectively removing them from the smoke.

The process begins by forcing dirty flue gas, the gas escaping from a smokestack, past two electrodes (electrical terminals) inside a pipe or smokestack. The first electrode is charged to a very high negative voltage, which causes the dirt particles to also become negatively charged as they move past. Further along, there is a second electrode consisting of metal plates charged to a high positive voltage. Since opposite charges attract, the negatively charged soot particles are then attracted to and stick onto the positively charged plates. Over time, the collecting plates need to be cleaned by either manually brushing them or using an automated mechanism.

Electrostatic smoke precipitators are highly effective at reducing pollution and can remove well over 99% of the particulates in flue gas. They are commonly used in industrial applications, especially for smoke, and their large size makes them more effective at removing particles from the air. However, they are not suitable for residential use due to the risk of ozone production, which can be harmful when inhaled.

Soil Pollution: Strategies for Control and Remediation

You may want to see also

Smoke is given an electric charge and passes by electrodes of the opposite charge, causing the particles to cling to them

Factories use electrostatic smoke precipitators, also known as scrubbers, to reduce smoke stack pollution. This technology has been around for over a century and is an effective way to remove soot and ash from dirty air.

Smoke is made up of tiny particles of soot, dispersed through hot, rising air. These particles are given an electric charge as they pass through a pipe or smokestack. This is achieved by forcing the dirty flue gas past two electrodes (electrical terminals), which are metal wires, bars, or plates. The first electrode is charged with a very high negative voltage, causing the dirt particles to also become negatively charged as they move past it.

Further along the pipe, there is a second electrode consisting of metal plates charged to a high positive voltage. Since opposite charges attract, the negatively charged soot particles are attracted to the positively charged plates and stick to them. Over time, the collecting plates need to be cleaned by either manually brushing them or using an automated mechanism.

This process of using static electricity to remove the soot from smoke is known as electrostatic smoke precipitation. It is a clever way to reduce pollution and improve the environment, ensuring that clean hot air emerges from the smokestack.

Noise Pollution and Insomnia: A Troubling Link?

You may want to see also

Electrostatic precipitators are designed differently for varying amounts of pollution and types of dirt particles

The design of electrostatic precipitators varies depending on the amount of pollution and types of dirt particles present. These factors influence the specific configuration, materials, and operating conditions required for effective pollution control. Here are some ways in which electrostatic precipitators are designed differently to address varying pollution levels and particle types:

- Gas Composition and Temperature: The composition and temperature of the gas stream play a crucial role in the design of electrostatic precipitators. Different industries produce flue gases with varying compositions, including nitrogen, carbon monoxide, nitrogen oxides, and sulfur dioxide. The temperature of the gas stream can range from above the dew point to as high as 400 °C in steel industry applications. These factors influence the choice of materials and the operating parameters of the precipitator.

- Particle Characteristics: The size, resistivity, and stickiness of the dirt particles impact the design of electrostatic precipitators. Smaller particles may require different electrode configurations or the use of two-stage precipitators to ensure sufficient charging time. Particles with very high or very low resistivity can be challenging to handle, and precipitators work best with particles of moderate resistivity. Sticky particles may necessitate the use of sealed plate precipitators to prevent leakage.

- Pollution Levels: The amount of pollution and the concentration of dirt particles in the gas stream affect the design of electrostatic precipitators. High levels of pollution or high soot concentration can lead to corona discharge closure, reducing the efficiency of the precipitator. In such cases, pre-treatment of the gas stream or the use of multiple precipitators may be necessary.

- Electrode Configuration: Electrostatic precipitators can have different electrode configurations, such as plate-wire, flat plate, or tubular designs. The choice of configuration depends on the volume of gas, particle characteristics, and the specific application. Plate-wire precipitators are suitable for large volumes of gas, while flat plate precipitators are effective for particles with high resistivity and small diameters. Tubular precipitators are ideal for controlling hazardous gases.

- Single-Stage vs. Two-Stage: Electrostatic precipitators can be designed as single-stage or two-stage units. Single-stage precipitators have parallel electrode configurations, with the charging and collection processes occurring in the same section. Two-stage precipitators are arranged in series, allowing more time for particle charging and reducing back corona. Two-stage precipitators are often used for low-volume and smaller-scale applications.

- Dry vs. Wet Precipitators: Dry electrostatic precipitators are used for collecting particles from dry environments, such as ash or cement. Wet electrostatic precipitators are designed to remove pollutants from wet gas streams, such as resin, oil, tar, and paint. They are particularly effective for capturing wet, sticky, or flammable particles and are commonly used in industrial settings to remove liquid droplets.

- Scalability: The level of pollution and the volume of gas being treated also influence the scalability of electrostatic precipitators. For higher pollution levels or larger gas volumes, larger precipitators or multiple units may be required. Very large power plants may have multiple precipitators, while residences typically use a single, smaller unit.

- Maintenance Considerations: The design of electrostatic precipitators should also take into account maintenance requirements, especially when dealing with sticky or corrosive particles. Regular cleaning of the collection plates and other components is essential to maintain efficiency and prevent system failures. Rapper coils or other vibration mechanisms may be incorporated into the design to facilitate the removal of accumulated particles.

Farming with Polluted Water: Sustainable Option for Oxygen-Deprived Farms?

You may want to see also

The effectiveness of electrostatic precipitators is impacted by the temperature and moisture content of the flue gas

The effectiveness of electrostatic precipitators (ESPs) is influenced by the temperature and moisture content of the flue gas, which in turn affects the resistivity of the particles being collected. ESPs work by applying a high-voltage direct current to charge particles, moving them to collecting surfaces, and then removing them. The resistivity of particles, or their resistance to transferring charge, is a critical factor in the collection process.

Temperature plays a significant role in the resistivity of particles. As temperature increases, resistivity tends to decrease. This is particularly important for particles with high resistivity, which are difficult to charge and require higher voltages to initiate corona generation. On the other hand, low-resistivity particles can become charged more easily but may also lose their charge rapidly, making it challenging to collect them on the collection plates. Adjusting the temperature can help reduce high resistivity.

Moisture content in the flue gas is another factor that affects particle resistivity. Increasing the moisture content, whether by spraying water or injecting steam into the ductwork preceding the ESP, generally leads to a decrease in resistivity. However, it is important to maintain gas conditions above the dew point to prevent corrosion issues in the ESP or downstream equipment.

The relationship between temperature, moisture content, and particle resistivity is complex and depends on various factors such as particle size, chemical composition, and other flue gas characteristics. ESPs work optimally under normal resistivity conditions, where particles do not rapidly lose their charge upon reaching the collection plates and can be effectively dislodged through rapping or vibrating.

By understanding and controlling the temperature and moisture content of the flue gas, operators can optimize the performance of ESPs and improve their effectiveness in reducing smoke stack pollution.

Air Pollutants: Understanding Their Impact and Our Health

You may want to see also

Electrostatic precipitators are not suitable for residential use due to the risk of ozone production

Electrostatic precipitators (ESPs) are filterless devices that use an electrical charge to remove air pollutants. They are highly effective in industrial settings, especially in removing fumes, oil, grease, and smoke. However, they are not suitable for residential use due to the risk of ozone production.

Ozone (O3), also known as smog, is a gas molecule composed of three oxygen atoms. It is harmful to human health, particularly for those with respiratory conditions such as asthma. Ozone aggressively attacks lung tissue, causing inflammation and damage to the airways.

ESPs emit ozone as a result of the electrical charging process. The charging and collection of particulate matter can lead to the production of ozone, which can adversely affect the health of individuals in enclosed spaces. While two-stage precipitators, which have separate charging and collection sections, can minimize ozone production, it is still a concern for residential use.

In addition, ESPs designed for industrial settings may not be as effective in residential spaces. They are typically designed to handle large volumes of gas and heavy dust loads, whereas residential air purification requires a more targeted approach.

Furthermore, ESPs can be challenging to maintain in a residential setting. The collection plates need to be cleaned periodically to remove accumulated particulate matter. In industrial settings, this can be done through automated processes, but in a home, it may require manual cleaning, which can be messy and time-consuming.

Therefore, while ESPs are highly effective in industrial air pollution control, they are not recommended for residential use due to the health risks associated with ozone production, as well as their large size and maintenance requirements.

Car Manufacturers: Reducing Pollution, Saving the Planet

You may want to see also

Frequently asked questions

Static electricity can be used to charge smoke particles, which are then attracted to and stick to a plate with the opposite charge, preventing them from escaping into the atmosphere.

Electrostatic precipitators, also known as scrubbers, use static electricity to remove soot from smoke. Dirty air is forced past two electrodes with opposite charges, causing the dirt particles to stick to the second electrode. The collecting plates then need to be shaken to empty away the soot.

Static electricity is an effective way to reduce pollution from smokestacks and has been used in industry for over a century. It can also be used in residential settings to improve air quality, although there are some health concerns associated with the release of ozone.

While static electricity can help reduce pollution, it is not 100% effective and some pollution will still remain. Additionally, electrostatic precipitators can be challenging and messy to clean, as the dust and smoke particles collect directly inside the appliance.