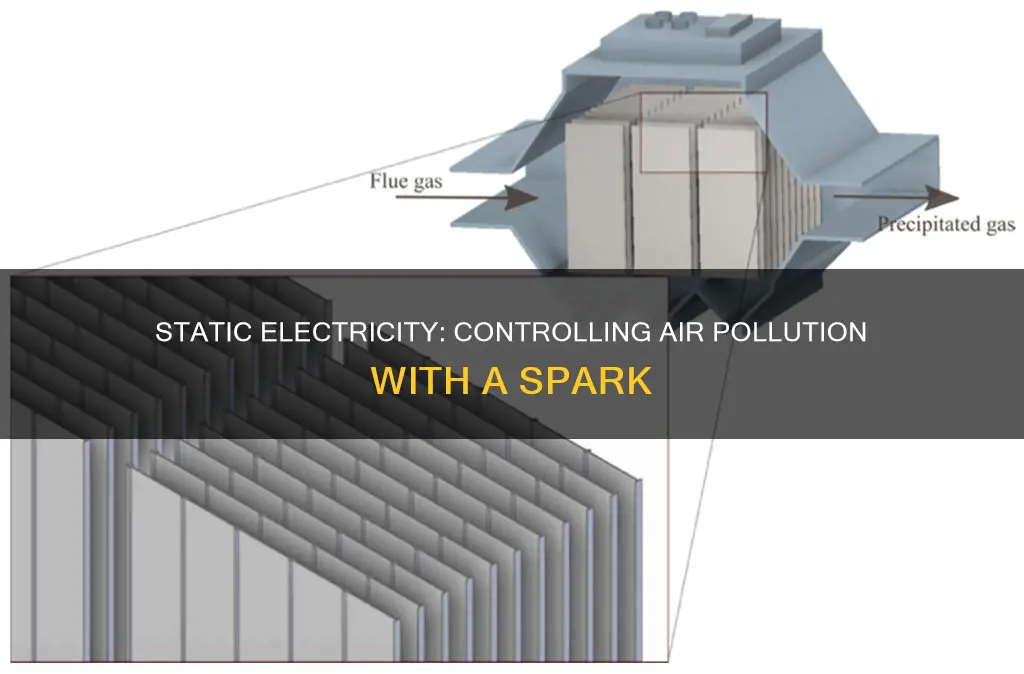

Static electricity is an important tool in the fight against air pollution. While it can be a nuisance in our daily lives, it has several beneficial applications, including in air pollution control. Electrostatic precipitators (ESPs) are a type of filter that uses static electricity to remove harmful particles from the air, such as those released by industrial facilities and power-generating stations. By applying a static charge to dirt particles in the air, they can then be collected on a plate with the opposite electrical charge, preventing them from being released into the atmosphere. This technology has been used to reduce pollution from factory smokestacks and improve air quality. ESPs are highly effective, capable of removing more than 99% of particulate matter, and have been an important solution for over a century.

| Characteristics | Values |

|---|---|

| How it works | Static electricity is applied to dirt particles in the air, which are then collected on a plate with the opposite charge |

| Devices | Electrostatic precipitators, air ionizers |

| Use cases | Factories use electrostatic precipitators to reduce pollution from smokestacks; air ionizers are used in homes to purify the air |

| Efficiency | Electrostatic precipitators have a collection efficiency of over 99% |

| Components | Gas distribution plates, discharge electrodes, collection surfaces, rappers |

| Types | Dry ESPs, wet ESPs |

What You'll Learn

- Electrostatic precipitators remove particles from gas streams by charging them and attracting them to collector plates of the opposite charge

- Electrostatic precipitators are also known as scrubbers and can remove over 99% of particulate matter

- Electrostatic precipitators are used in factories to reduce pollution from smokestacks

- Air ionizers use static electricity to purify the air in homes by attracting charged dust and smoke particles to a plate with the opposite charge

- The performance of electrostatic precipitators can be affected by particle resistivity

Electrostatic precipitators remove particles from gas streams by charging them and attracting them to collector plates of the opposite charge

Electrostatic precipitators (ESPs) are an effective way to control air pollution. They are used to remove harmful particles from gas streams, which would otherwise be released into the air at industrial facilities and power-generating stations.

An ESP works by using electrical energy to charge particles either positively or negatively. This is achieved by passing the dirty flue gas past two electrodes (electrical terminals), which can be in the form of metal wires, bars, or plates inside a pipe or smokestack. The first electrode is charged to a very high negative voltage, which gives the dirt particles a negative charge as they move past it. Further along, there is a second electrode consisting of metal plates charged to a high positive voltage. The negatively charged particles are then attracted to these positively charged collector plates, where they stick.

The collected particles can be removed from the collector plates in two ways: as dry material (dry ESPs) or washed from the plates with water (wet ESPs). In dry ESPs, the plates are cleaned by applying mechanical impulses or vibrations to knock the particles loose. Wet ESPs, on the other hand, are used when gas streams contain sticky particles with low resistivity, and the plates are rinsed with water. ESPs can achieve collection efficiencies greater than 99%, making them extremely effective at reducing air pollution.

The basic principle behind ESPs is the attraction between charged particles caused by static electricity. This technology has been used for over a century to reduce pollution from factory and power-plant smokestacks. By applying a static charge to dirt particles in the air and then collecting them on a plate with the opposite charge, ESPs help to maintain clean air while allowing industries to continue operating.

Pollution Masks: Safe for Exercise?

You may want to see also

Electrostatic precipitators are also known as scrubbers and can remove over 99% of particulate matter

Electrostatic precipitators (ESPs) are devices that use static electricity to remove harmful particles from the air, thus controlling air pollution. They are commonly used in industrial facilities and power-generating stations to reduce the amount of particulate matter released into the atmosphere.

ESPs work by using electrical energy to charge particles either positively or negatively. These charged particles are then attracted to collector plates carrying the opposite charge, where they can be collected and removed. The collector plates can be cleaned manually or automatically, depending on the type of ESP. There are two main types of ESPs: dry ESPs and wet ESPs. Dry ESPs use mechanical impulses or vibration to knock loose the collected particles, while wet ESPs rinse the plates with water.

The effectiveness of ESPs is influenced by particle resistivity, which affects the deposition and removal of particles from the collection plates. However, they have been shown to be extremely effective, with collection efficiencies greater than 99%. This makes them a valuable tool in the effort to reduce air pollution and improve air quality.

ESPs have been used for over a century to control pollution from factory and power-plant smokestacks. They are also known as "scrubbers" because they can snatch soot and ash from dirty air as it flows along a pipe. By removing these harmful particles, ESPs help to reduce pollution and improve the environment.

In addition to their use in industrial settings, some people also purchase air ionizers, which work on a similar principle to ESPs, to freshen and purify the air in their homes. These devices strip electrons from smoke molecules, dust particles, and pollen, charging them and then attracting them to a plate with the opposite charge. Over time, this helps to reduce the amount of pollution in the air.

Airborne Pathogens: Pollution's Impact on Health

You may want to see also

Electrostatic precipitators are used in factories to reduce pollution from smokestacks

Electrostatic precipitators are an ingenious application of static electricity, harnessing its ability to attract charged particles to control air pollution. These devices are employed in industrial settings, particularly factories, to mitigate the release of harmful pollutants from smokestacks.

At its core, an electrostatic precipitator utilises electrical forces to attract and capture particulate matter, such as soot and ash, present in the smoke emitted by factories. The fundamental principle behind this technology is the attraction between charged particles caused by static electricity. By imparting an electric charge to the smoke particles, they can be manipulated and collected, preventing their release into the atmosphere.

The process begins by applying a static charge to the dirt particles in the smoke. This is achieved by guiding the dirty flue gas, or smoke, past negatively charged electrodes, typically in the form of metal wires, bars, or plates. As the particles pass by, they acquire a negative charge themselves. Subsequently, the smoke, now consisting of negatively charged particles, encounters a second set of electrodes with a positive charge. These positively charged plates attract and capture the negatively charged soot particles, drawing them out of the air stream.

To maintain the efficiency of the precipitator, the collecting plates must be periodically cleaned to remove the accumulated soot. This can be done manually by brushing the plates or automatically through a process known as "rapping," which involves shaking or brushing the plates to dislodge the collected particles.

Electrostatic precipitators are highly effective in reducing air pollution, with reported removal efficiencies exceeding 99% for particulate matter. They play a crucial role in mitigating the environmental impact of industrial processes, ensuring that the air released from smokestacks is significantly cleaner and less harmful to the environment.

By leveraging the principles of static electricity, electrostatic precipitators offer a practical and innovative solution to the longstanding issue of air pollution from factories and industrial facilities. Through the strategic application of electrical charges, these devices capture and contain pollutants, contributing to a cleaner and more sustainable environment.

Coal Pollution: Deteriorating Our Atmosphere?

You may want to see also

Air ionizers use static electricity to purify the air in homes by attracting charged dust and smoke particles to a plate with the opposite charge

Electrostatic precipitators are a type of filter used to help control air pollution. They work by applying a static charge to dirt particles in the air, which are then attracted to a plate with the opposite charge, where they can be collected and removed. This process is used in industrial settings to reduce pollution from smokestacks, as well as in homes to improve air quality.

In the context of air ionizers, the devices use static electricity to strip electrons from smoke molecules, dust particles, and pollen in the air. These charged particles are then attracted to and stick to a plate within the device with the opposite charge. Over time, this process draws much of the pollution out of the air, improving indoor air quality.

It is important to note that charged particles can also stick to neutral surfaces, such as walls near the ionizer, which can make them dirty and difficult to clean. Additionally, electrostatic precipitators are not 100% effective, and some pollution may remain. However, they are still a valuable tool for reducing air pollution and improving air quality, with some devices capable of removing more than 99% of particulate matter.

Overall, air ionizers that utilize static electricity can be an effective way to purify the air in homes and reduce the presence of charged dust and smoke particles, contributing to a healthier and more comfortable indoor environment.

Contaminated Catch: Polluted Water's Impact on Edible Fish

You may want to see also

The performance of electrostatic precipitators can be affected by particle resistivity

Electrostatic precipitators (ESPs) are devices that use static electricity to remove fine particles, such as dust and smoke, from a flowing gas stream. They are commonly used in industrial settings to reduce air pollution. The basic principle behind ESPs is the use of an induced electrostatic charge to attract and collect particles on oppositely charged plates. This process is highly effective in removing pollutants from the air, with efficiency rates greater than 99%.

The performance of ESPs can be influenced by various factors, one of which is particle resistivity. Particle resistivity refers to the resistance of a particle to transferring an electrical charge. It is determined by the particle's chemical composition and the operating conditions of the flue gas, such as temperature and moisture. There are three main categories of particle resistivity: high, moderate (normal), and low.

Particles with high resistivity are difficult to charge and do not readily give up their charge once they reach the collection plate. This can lead to a buildup of negative charge on the plates, inhibiting the deposition of other particles. On the other hand, particles with low resistivity easily become charged and quickly release their charge to the collection plate. They take on the charge of the plate, bounce off, and become re-entrained in the gas stream. In both cases, the attractive and repulsive electrical forces that are crucial for efficient collection are diminished. ESPs function optimally with particles that exhibit moderate resistivity.

To optimize the performance of ESPs, it is essential to maintain particle resistivity within the moderate range. This can be achieved through various methods, including adjusting the temperature, introducing additional moisture, adding conditioning agents to the gas stream, or increasing the collection surface area. By doing so, the negative impacts of high and low resistivity can be mitigated, ensuring efficient particle collection and improved air pollution control.

Additionally, the physical design of the precipitator, the gas stream velocity, and the moisture content of the gas stream can also influence the performance of ESPs. It is important to consider these factors when designing and operating ESPs to ensure optimal efficiency in air pollution control.

How Can We Clean Our Water?

You may want to see also

Frequently asked questions

An electrostatic precipitator (ESP) is a filter that uses static electricity to remove harmful particles from the air. It does this by applying an electric charge to dirt particles in the air, which are then collected on a plate with the opposite charge.

Electrostatic precipitators use electrical energy to charge particles positively or negatively. These charged particles are then attracted to collector plates carrying the opposite charge. The particles are then removed from the collector plates as dry material or washed from the plates with water.

Electrostatic precipitators are used in industrial facilities and power-generating stations to reduce air pollution. Factories use them to reduce pollution coming from their smokestacks. They can also be purchased for home use to purify the air.