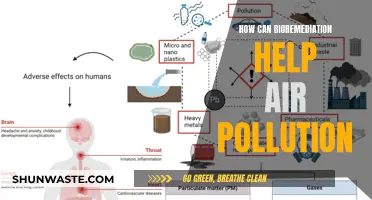

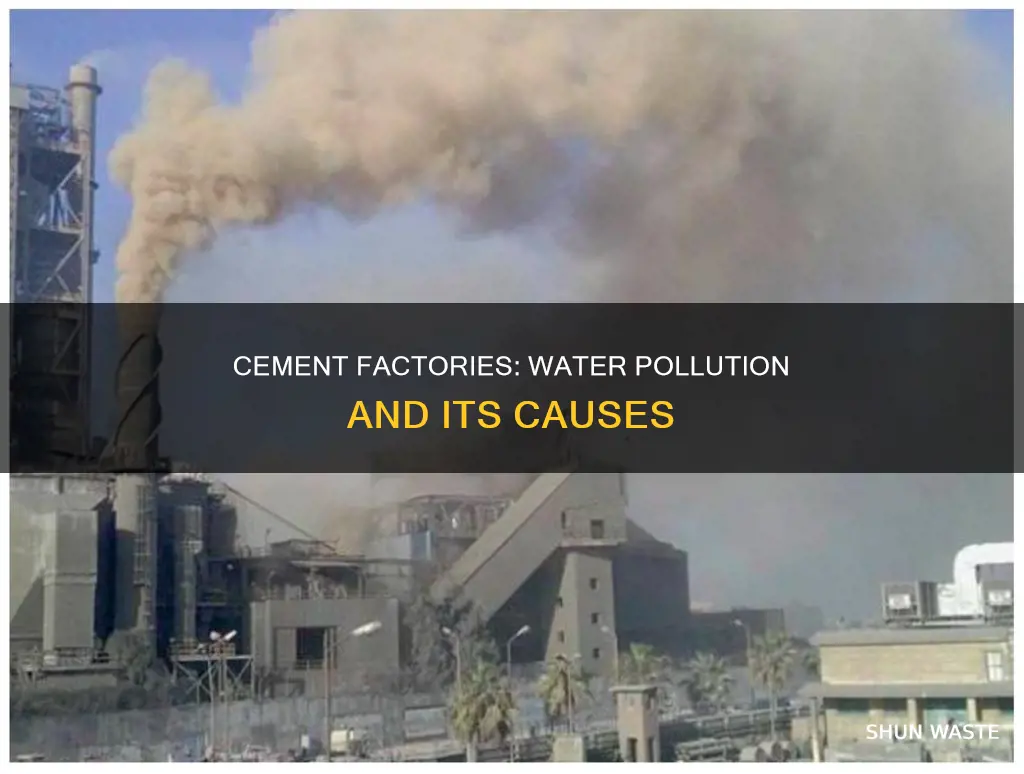

Cement is a key ingredient in concrete, the most widely used man-made material on the planet. The cement industry is the third-largest industrial source of pollution, emitting more than 500,000 tons per year of sulfur dioxide, nitrogen oxide, and carbon monoxide. These emissions have been linked to an array of health issues, including respiratory and cardiovascular diseases, lung cancer, and premature death.

The cement industry's environmental impact includes the release of greenhouse gases and pollutants, contributing to climate change, air and water pollution, and landscape disruption. These effects have a direct impact on biodiversity, human health, and overall environmental degradation.

Cement production requires substantial energy consumption, and the processes involved release large volumes of harmful emissions into the water.

| Characteristics | Values |

|---|---|

| Particulate matter | PM10, PM2.5 and PM1 |

| Nitrogen oxides | |

| Sulphur dioxide | |

| Carbon monoxide | |

| Carbon dioxide | |

| Chlorides | |

| Fluorides | |

| VOC emissions | |

| Heavy metals |

What You'll Learn

- Nitrogen oxides (NOx) emissions from cement factories can cause respiratory problems and contribute to global warming

- Sulphur dioxide (SO2) emissions from cement production can aggravate respiratory diseases and contribute to acid rain

- Carbon monoxide (CO) emissions from cement plants can cause harmful health effects by reducing oxygen delivery to the body's organs and tissues

- Particulate matter (PM) emissions from cement facilities are significant, and cement is considered the world's most serious pollutant

- Fugitive emissions from cement manufacturing are difficult to trace and unknowingly contribute to ambient air pollution

Nitrogen oxides (NOx) emissions from cement factories can cause respiratory problems and contribute to global warming

Nitrogen oxides (NOx) are among the primary emissions of the cement industry, along with carbon monoxide, carbon dioxide, sulphur dioxide, and small quantities of heavy metals. NOx is a catch-all term for oxides of nitrogen, typically consisting of 95% nitric oxide (NO) and 5% nitrogen dioxide (NO2).

NOx emissions from cement factories can have detrimental effects on both environmental and human health. When NOx reacts with water vapour in the atmosphere, it forms nitric acid, contributing to acid rain. Acid rain harms soil health and kills plants, including crops that provide food. NOx is also implicated in the formation of photochemical smog through the production of ozone in the troposphere. Smog poses a significant health risk to individuals with respiratory conditions, such as asthma, and has been linked to premature deaths.

The production of NOx in cement kiln systems occurs through three primary processes: Thermal NOx, Fuel NOx, and Prompt NOx. Thermal NOx is formed through the conversion of N2 in the air at high temperatures. Fuel NOx is produced when nitrogen in the fuel oxidises during combustion. Prompt NOx, which is negligible in cement kilns using modern burners, occurs when carbon radicals in the flame oxidise N2.

To reduce the harmful effects of NOx emissions, it is essential to implement measures to minimise their release into the atmosphere. This can be achieved through the optimisation of production processes, the adoption of cleaner technologies, and the utilisation of alternative fuels and raw materials. Additionally, continuous emissions monitoring systems can help track and manage NOx emissions from cement factories.

Pollution Challenges in City Planning: A Ground-Level View

You may want to see also

Sulphur dioxide (SO2) emissions from cement production can aggravate respiratory diseases and contribute to acid rain

Sulphur dioxide (SO2) is a colourless gas with a pungent odour that can cause an irritating sensation similar to shortness of breath. It is a major air pollutant and is released during cement production, largely determined by the sulphur content of the raw materials used.

The production of cement is responsible for a notable proportion of global CO2 emissions, and it is also a significant emitter of other harmful substances, including SO2. In the UK, for example, the manufacture of cement resulted in 3,700 metric tons of SO2 emissions in 2017, a significant decrease from 42,200 metric tons in 1990.

SO2 emissions from cement factories can have detrimental effects on both the environment and human health. As a precursor to acid rain, SO2 contributes to environmental degradation. Additionally, exposure to SO2 can aggravate respiratory diseases. Cement production also releases particulate matter, which, according to the World Health Organization (WHO), can cause respiratory and cardiovascular diseases, lung cancer, and premature death.

The high temperatures required for cement production, often achieved through the combustion of fossil fuels, are a significant source of various air pollutants, including SO2. The burning of fossil fuels, such as coal, oil, or natural gas, releases SO2 as a byproduct. Furthermore, the calcination of limestone, a crucial step in cement production, also emits SO2 due to the decomposition of calcium carbonate.

To mitigate the environmental and health impacts of SO2 emissions, it is essential to adopt sustainable practices in the cement industry. This includes reducing the clinker content in cement, improving energy efficiency, and transitioning to renewable energy sources. By implementing such measures and utilizing emission monitoring systems, it is possible to minimize the negative consequences of SO2 emissions from cement production.

How Storm Surges Can Cause Air Pollution

You may want to see also

Carbon monoxide (CO) emissions from cement plants can cause harmful health effects by reducing oxygen delivery to the body's organs and tissues

Carbon monoxide (CO) is one of the primary emissions from cement plants, alongside nitrogen oxides (NOx), sulphur dioxide (SO2), and carbon dioxide (CO2). While the cement industry is vital to the global economy, it is also one of the most polluting.

CO emissions from cement plants can have harmful health effects by reducing oxygen delivery to the body's organs and tissues. This is due to the high combustion temperatures and fuel combustion processes used in cement production. The environmental impact of these emissions is also significant, contributing to global warming and climate change.

To reduce the harmful health and environmental effects of CO emissions, the cement industry must implement strategies to cut carbon emissions. This includes improving energy efficiency, switching to lower-carbon fuels, promoting material efficiency, and advancing innovative near-zero emission production methods.

Additionally, the development and deployment of new technologies, such as carbon capture and storage (CCS), are essential to reducing CO emissions from cement plants and achieving net-zero emissions targets. International collaboration and supportive policies from governments are also crucial in addressing this global issue.

Pollution's Impact on Digestion: A Health Concern?

You may want to see also

Particulate matter (PM) emissions from cement facilities are significant, and cement is considered the world's most serious pollutant

Cement manufacturing is a significant contributor to air pollution, with the sector accounting for around 7% of global carbon emissions. Particulate matter (PM) emissions from cement facilities are a major concern, and the industry is considered one of the world's most serious polluters.

Cement production is a multi-step process, and fugitive emissions—pollutants that escape from an unknown source—are a critical issue. Fugitive emissions are challenging to trace and control, and they contribute significantly to ambient air pollution.

The various stages of cement production, from mining to packaging, release pollutants such as dust or PM, nitrogen oxides (NOx), sulfur oxides (SOx), carbon oxides, and methane. These emissions have severe impacts on human health and the environment.

To address these emissions, various air pollution control measures are implemented in the cement industry. Technological advancements, such as electrostatic precipitators, baghouses, and emerging solutions like advanced filtration systems and carbon capture technologies, play a crucial role in reducing PM and gaseous emissions.

The cement industry's sustainability challenges are significant, and conventional pollution control equipment has limitations. Integrating innovative technologies with regulatory frameworks is essential to effectively reduce the sector's environmental footprint and protect human health and the planet.

Ocean Pollution: Harming Humans, Destroying Marine Ecosystems

You may want to see also

Fugitive emissions from cement manufacturing are difficult to trace and unknowingly contribute to ambient air pollution

Fugitive emissions from the cement industry are a critical concern. These emissions are challenging to manage because they are released from unclear sources, making them difficult to trace and control. They are produced during every stage of the cement manufacturing process and significantly contribute to ambient air pollution.

The cement manufacturing process involves multiple steps, each of which generates fugitive emissions. Firstly, raw materials, primarily limestone, are mined from quarries through activities such as drilling, blasting, crushing, transportation, and stockpiling, all of which emit particulate matter and carbon dioxide. Secondly, during the raw material preparation stage, the raw materials are mixed and ground using dry, wet, or semi-dry methods, leading to fugitive particulate matter emissions during grinding and transportation to the kiln.

The third stage is kiln processing, where the raw materials are combusted to form clinkers, or complex spherical nodules. This stage involves drying or preheating, melting, and clinker cooling. Calcination, which involves burning the raw mix at high temperatures, releases carbon dioxide, SOx, NOx, carbon monoxide, and hydrocarbons. These emissions arise from the burning of the mixture and the fuel used.

The final stage is cement milling, where the clinkers are ground into a fine powder, and certain chemicals are added to set the cement. This stage also emits particulate matter, SOx, and NOx. Additionally, throughout the manufacturing process, VOCs are released during other associated industrial processes.

The problem of fugitive emissions in the cement industry is exacerbated by the fact that many cement factories continue to have excessive emissions despite installing pollution control technologies. This results in significant fines, and in some cases, the shutdown of factories for exceeding pollution standards. The high energy requirements of cement production, predominantly met by fossil fuels, further contribute to the industry's carbon footprint and air pollution.

To address these issues, it is essential to adopt a comprehensive approach that integrates technological advancements and regulatory frameworks. Implementing advanced filtration technologies, such as electrostatic precipitators and fabric filters, can significantly reduce particulate matter emissions. Additionally, adopting alternative fuels with lower pollutant contents and optimizing energy efficiency can minimize harmful gas emissions.

Stringent emission standards and incentives for adopting best practices are crucial for encouraging the cement industry to reduce its environmental impact. Continuous monitoring devices and real-time data play a vital role in providing transparency, ensuring compliance, and enabling industries to make informed decisions to mitigate their environmental footprint.

Air Pollution's Soil Loss: A Troubling Connection

You may want to see also

Frequently asked questions

The cement industry affects water sources in several ways. Firstly, it requires significant water consumption, impacting water availability for other uses. Secondly, the industry discharges untreated or inadequately treated wastewater into rivers and other water bodies, contaminating them with pollutants such as heavy metals, suspended solids, and high levels of nutrients like phosphate and nitrate. These pollutants can lead to eutrophication, increased water pH, and oxygen depletion, harming aquatic ecosystems and rendering water unfit for drinking and domestic use.

Contaminated water from cement factories can cause skin irritation and cholera in humans. Additionally, the presence of heavy metals and other toxic pollutants in water sources can lead to neurological problems, asthma, respiratory diseases, and even premature death.

Cement factories can implement several measures to reduce water pollution. Firstly, they should treat their wastewater adequately before discharging it into water bodies, ensuring that it meets regulatory standards. Secondly, they can optimise their water usage and adopt water-saving technologies to reduce their water consumption. Finally, they can explore alternative raw materials and fuels with lower pollutant contents to minimise the release of harmful substances into water sources.

![Emission reduction Q & A-3R practice field manual of the factory (2003) ISBN: 4879732516 [Japanese Import]](https://m.media-amazon.com/images/I/51A4WbNKK4L._AC_UL320_.jpg)