Steel is an alloy of iron, carbon, and manganese, with trace amounts of other elements. It is one of the most commonly used metals worldwide, with innumerable applications. The process of making steel involves two primary methods: Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF). However, the production of steel has significant environmental implications. It is a major contributor to air, water, and soil pollution, releasing harmful emissions and consuming substantial energy, which leads to increased greenhouse gas emissions. The areas closest to steel plants bear the brunt of the pollution generated, and the emissions from steel production have far-reaching effects on ecosystems and human health. While steel is highly sustainable due to its strength and recyclability, the industrial processes involved in its production have made it one of the main drivers of climate change.

| Characteristics | Values |

|---|---|

| Air emissions | CO, SOx, NOx, PM2, coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur, coke dust, SO2, and NOx |

| Water emissions | Water used to cool coke after baking becomes contaminated with coke breezes and other compounds |

| Solid waste | Slag, the largest portion of iron-making by-products, is sold to the construction industry |

| Greenhouse gas emissions | Steel production accounts for 6.5% of global CO2 emissions and 30% of U.S. greenhouse gas emissions in 2021 |

| Health hazards | The molten metals used in steel-making emit electromagnetic, infrared, and ultraviolet radiation, which can be hazardous to workers' health |

| Environmental impact | Acid rain, soil composition changes, water body contamination, vegetation damage, and climate change |

Greenhouse gas emissions

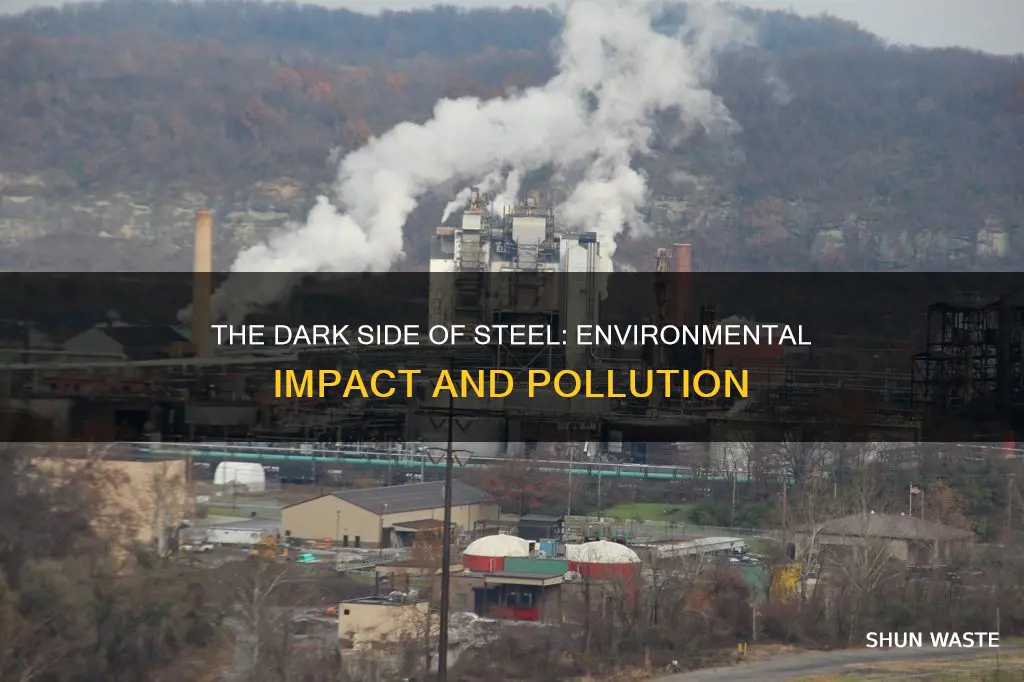

Steel production affects air quality and worsens atmospheric conditions. The industrial processes involved in steel production release greenhouse gases, particulate matter, and volatile organic compounds into the air. These pollutants cause serious harm to human health and the environment. The areas closest to the steel plants are the most affected by the pollution generated during steel manufacturing. The emission of fine particulate matter (PM2.5 and PM10), nitrogen oxides (NOx), and sulphur dioxide (SO2) are among the most harmful pollutants.

The production of coke, a raw material essential for steel manufacturing, is one of the major sources of pollution. Air emissions from coke ovens include coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur, and coke dust. Water used to cool coke after baking also becomes contaminated, although it can be easily reused and filtered.

The steel industry is a significant contributor to global CO2 emissions, with 6.5% derived from iron and steel production. The total CO2 emissions from the iron and steel sector have risen over the past decade due to increasing steel demand. To achieve net-zero emissions by 2050, substantial cuts in CO2 emissions are essential. Short-term reductions can be achieved through energy efficiency improvements and increased scrap collection for scrap-based production. However, the technical potential for energy efficiency improvements is limited, and the supply of scrap is finite.

To achieve more substantial reductions in emissions intensity, new technologies and processes must be adopted. These include electricity-based production, hydrogen usage, and carbon capture and storage (CCUS). The use of renewable electricity, low-carbon hydrogen, and CO2 infrastructure can lessen the carbon intensity of steelmaking. Innovative technologies for primary steel production, such as the H2-DRI route and CCUS-equipped routes, are expected to account for more than 8% of primary production by 2030.

In Europe, steel producers are actively developing decarbonization strategies and running pilot plants to assess different production technologies. These include efficiency programs that optimize raw materials, increase fuel injection, and utilize coke oven gas as an energy source. Green hydrogen-based DRI production, in combination with electric arc furnaces (EAFs), offers a technically proven method for nearly emission-free steel production.

Air Conditioners: Polluting Palm Beach's Air?

You may want to see also

Air pollution

Steel production releases a wide range of pollutants into the air, including particulate matter, volatile organic compounds (VOCs), and greenhouse gases. The industrial processes involved in steel production emit microscopic elements of solid and liquid substances, known as particulate matter, into the atmosphere. These particles can be inhaled and have serious impacts on human health, causing respiratory issues such as asthma, chronic bronchitis, and pulmonary diseases. They also contribute to climate change by trapping heat and altering weather patterns.

Volatile organic compounds (VOCs) are another significant pollutant emitted during steel processing, particularly in annealing and heat treatment. VOCs contribute to the formation of ground-level ozone, exacerbating air pollution and leading to photochemical smog. This type of pollution is especially harmful to human health and ecosystems in large urban areas. Additionally, the use of carbon-rich fuels, such as coke, a type of coal, releases naphthalene, a potentially carcinogenic substance, into the atmosphere.

The production of steel is energy-intensive, often relying heavily on fossil fuels, particularly coal. This dependence on fossil fuels makes the steel industry one of the major contributors to air pollution. The process of mining iron ore, the first step in steel production, involves blasting with coal, releasing pollutants such as sulfur oxides, particulate matter, and fugitive dust. The direct emissions from steel plants, including sulfur dioxide (SO2) and nitrogen oxide (NOx), have severe local impacts, affecting communities closest to the steel production sites.

To mitigate the environmental and health impacts of steel production, advanced technologies, and data analytics are being employed. Systems like Oizom and Kunak use sensors to detect and measure pollutants in real time, enabling timely responses to toxic gases and other harmful emissions. These technologies facilitate informed decision-making, aiding in the implementation of preventive measures and the improvement of production processes to reduce emissions and their environmental consequences.

While steel production has a significant impact on air pollution, ongoing research and the development of new technologies offer hope for reducing these emissions. For example, Arizona State University researchers are working on electrifying the steel manufacturing process to reduce environmental and health hazards. Additionally, the Clean Fuels and Products Shot initiative aims to decarbonize the fuel industry, including sectors like aircraft and marine fuels, which are challenging to decarbonize. These collective efforts demonstrate a commitment to finding sustainable solutions and mitigating the air pollution caused by steel production.

Hydropower's Pollution Paradox: Power vs. Pollution

You may want to see also

Water pollution

Steel production has a significant environmental impact. It is among the most carbon-intensive manufacturing processes, producing about 7% of carbon dioxide emissions globally. The steel industry is the largest consumer of energy in the world among industrial sectors.

The major sources of pollution from steel production include coking and iron-making. Coke production releases air emissions such as coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur, and coke dust. Water emissions come from the water used to cool coke after it has finished baking. This quenching water becomes contaminated with coke breezes and other compounds. While most pollutants can be removed by filtration, the water-intensive nature of the industry remains a concern, especially with decreasing freshwater sources.

To address these issues, researchers are working on developing hydrogen-plasma-smelting-reduction technology to reduce carbon emissions during steelmaking. This involves using hydrogen to replace carbon-emitting sources or ore to produce iron without emitting carbon dioxide. Electrification of steel manufacturing is also being explored to reduce potential hazards to workers and the environment from the electromagnetic, infrared, and ultraviolet radiation emitted during the manufacturing process.

Fabric Softeners: Are They Polluting Your Indoor Air?

You may want to see also

Solid waste

One of the key challenges in solid waste management in the steel industry is waste minimization. Despite efforts to reduce waste generation, the inherent nature of industrial processes results in solid waste as a by-product. For example, slag, the limestone and iron ore impurities collected during steelmaking, used to be considered waste but is now classified as a "by-product" due to its intensive reuse in the construction industry. Additionally, dust emissions, a common issue in steel plants, can be mitigated through slag treatment, as demonstrated by Baosteel's successful experience in saving space and energy while reducing dust emissions.

Recycling and reuse play a crucial role in solid waste management in the steel industry. Recycling helps prevent the waste of useful materials, reduce the consumption of raw materials, lower energy usage, and minimize air and water pollution associated with conventional waste disposal methods. Companies like Schnitzer Steel Industries Inc. have built successful businesses around recycling scrap metal and manufacturing finished steel products. Furthermore, the steel industry itself is actively recycling and incorporating steelmaking wastes back into their processes, such as using mill scale and slag in sintering and other industrial processes.

Some steel companies have implemented innovative projects under the "Wealth from Waste" initiative to transform solid waste into valuable resources. For instance, Jindal Steel and Power Limited (JSPL) has adopted the three R's: Recycle, Reduce, and Reuse. They temporarily store solid waste at the Parsada dump yard before transporting it to the sinter plant for further reuse. JSPL has also installed a bio-methanation plant in association with BARC, Mumbai, for bio-gas production using biodegradable waste from residential areas.

Overall, solid waste management in the steel industry presents opportunities for environmental improvement through waste minimization, hazardous waste management, resource recovery, and recycling and reuse initiatives. With the development of appropriate guidelines and technological interventions, the steel industry can make significant strides toward sustainable waste management practices.

Lyocell's Pollution Problem: Is This Fabric Eco-Friendly?

You may want to see also

Soil pollution

Steel production has a significant impact on the environment, including air, water, and soil pollution. While steel is a highly sustainable material due to its strength, longevity, and recyclability, its production process is highly polluting. It releases various pollutants into the air, including fine particulate matter, nitrogen oxides (NOx), sulphur dioxide (SO2), greenhouse gases, and volatile organic compounds. These emissions contribute to climate change and have detrimental effects on both human health and the environment.

Another study in Loudi City, Hunan Province, China, utilized magnetic and non-magnetic methods to assess the degree of heavy metal pollution in farmland soil irrigated with polluted river water near a steel plant. The results indicated enhanced magnetic concentration values in the upper arable soil layer, confirming that the pollution in the farmland soil was primarily due to irrigation with contaminated wastewater.

Furthermore, a study in South China revealed thallium (Tl) contamination in arable soils and vegetables around a steel plant. Thallium is a highly toxic rare element that can cause severe neurological damage or even death. The presence of thallium and other heavy metals in the soil and vegetables cultivated near the steel plant raised concerns about potential health risks for the local population consuming these vegetables.

To mitigate the environmental impact of steel manufacturing, the implementation of emission control technologies and the optimization of industrial processes are essential. The steel industry is working towards reducing its energy consumption and pollutant emissions through innovation, low-carbon technologies, and improved resource efficiency. Additionally, accurate and continuous air quality monitoring systems, such as those using advanced sensors, play a crucial role in detecting and controlling emissions, ensuring a safe working environment, and facilitating informed decision-making to minimize pollution.

Essential Oils: Air Pollution or Purely Natural?

You may want to see also

Frequently asked questions

Yes, making steel causes pollution. The industrial processes involved in steel production release greenhouse gases, particulate matter, and volatile organic compounds into the air.

The sources of pollution in steel production include iron making, coking, smelting of ores, and other processes. Coke production is one of the major pollution sources, releasing air and water emissions.

The environmental impacts of steel production include air emissions (CO, SOx, NOx, PM2), wastewater contaminants, hazardous wastes, and solid wastes. These pollutants contribute to climate change and cause serious harm to human health and the environment.